Preparation method of g-C3N4 coated metal nano composite with core-shell structure

A nanocomposite, core-shell structure technology, applied in the field of nanomaterial preparation, can solve the problems of application limitation and expensive equipment, and achieve the effects of shortened reaction time, rapid reaction and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

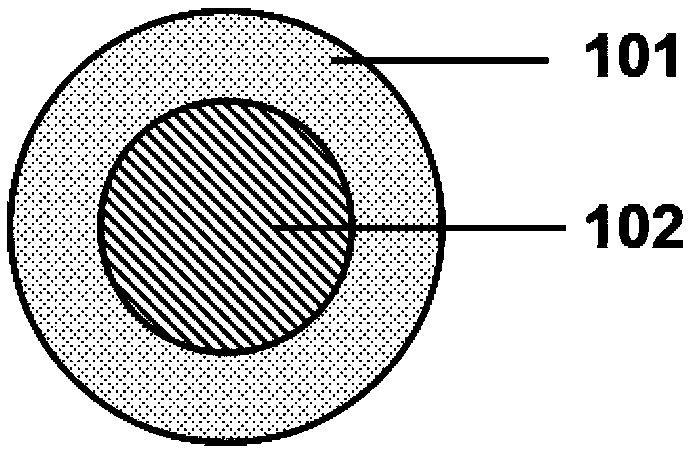

[0032] figure 1 For the coating type g-C in the method of the present invention 3 N 4 / Schematic diagram of the structure of the metal nanocomposite. Such as figure 1 As shown, the core-shell coating material nanoparticles include: a carbonitride shell layer 101 coated on the outside; an inner metal core layer 102, and Fe nanoparticles are selected in this embodiment.

[0033] The carbonitride shell layer 101 is generally g-C 3 N 4 , or carbon-nitrogen compounds of similar composition.

[0034] The metal core 102 can be prepared by direct current arc method, and its particle diameter is 1 to 300 nm.

[0035] Further, the nanoparticles 102 in this example are prepared using hydrogen gas and argon gas, and cooled with cooling water, and the particle diameter of the metal nanoparticles is 1 to 200 nm.

[0036] Simultaneously, the present invention provides above-mentioned embodiment preparation method:

[0037] figure 2 Coated g-C shown 3 N 4 / Flowchart of the prepar...

Embodiment 2

[0050] figure 1 For the coating type g-C in the method of the present invention 3 N 4 / Schematic diagram of the structure of the metal nanocomposite. Such as figure 1 As shown, the core-shell coating material nanoparticles include: a carbonitride shell layer 101 coated on the outside; an inner metal core layer 102, and Co nanoparticles are selected in this embodiment.

[0051] The carbonitride shell layer 101 is generally g-C 3 N 4 , or carbon-nitrogen compounds of similar composition.

[0052] The metal core 102 can be prepared by direct current arc method, and its particle diameter is 1 to 300 nm.

[0053] Further, the nanoparticles 102 in this example are prepared using hydrogen gas and argon gas, and cooled with cooling water, and the particle diameter of the metal nanoparticles is 1 to 200 nm.

[0054] Simultaneously, the present invention provides above-mentioned embodiment preparation method:

[0055] figure 2 Coated g-C shown 3 N 4 / Flowchart of the prepar...

Embodiment 3

[0067] figure 1 For the coating type g-C in the method of the present invention 3 N 4 / Schematic diagram of the structure of the metal nanocomposite. Such as figure 1 As shown, the core-shell coating material nanoparticles include: a carbonitride shell layer 101 coated on the outside; and a metal core layer 102 inside, and Ni nanoparticles are selected in this embodiment.

[0068] The carbonitride shell layer 101 is generally g-C 3 N 4 , or carbon-nitrogen compounds of similar composition.

[0069] The metal core 102 can be prepared by direct current arc method, and its particle diameter is 1 to 300 nm.

[0070] Further, the nanoparticles 102 in this example are prepared using hydrogen gas and argon gas, and cooled with cooling water, and the particle diameter of the metal nanoparticles is 1 to 200 nm.

[0071] Simultaneously, the present invention provides above-mentioned embodiment preparation method:

[0072] figure 2 Coated g-C shown 3 N 4 / Flowchart of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com