Automatic production line for fresh bamboo shoots

An automatic production line and technology of bamboo shoots, applied in food processing, peeling of vegetables or fruits, food science, etc., can solve the problems of high labor intensity, low production efficiency, cumbersome and other problems of workers, and achieve good freshening effect and high cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

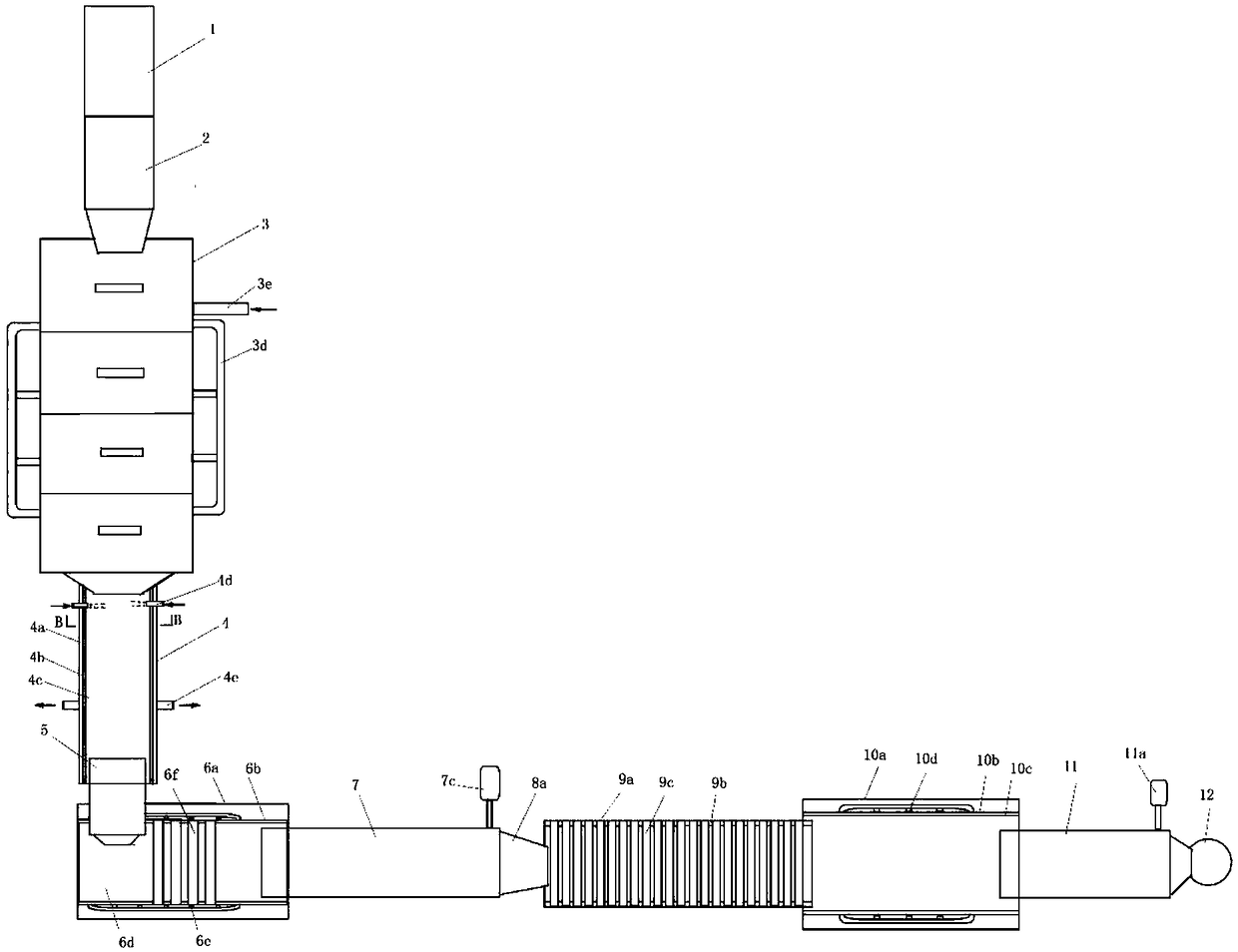

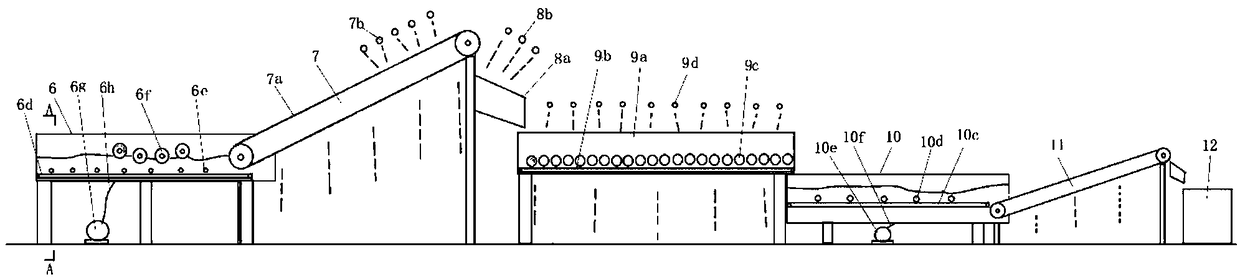

[0022] Such as Figure 1 to Figure 5 As shown, the fresh-keeping bamboo shoots automatic production line of the present invention comprises the horizontal feeding conveyor 1, the first climbing feeding conveyor 2, the closed continuous bamboo shoot casing 3, the cooling tank 4, the second climbing conveyor 5 arranged in sequence , Scrubbing tank 6, climbing type thinning conveying cleaning machine 7, flipping cleaning mechanism, desilting cleaning tank 9, air bubble cleaning tank 10, filter water conveyor 11. For better visibility, figure 1 The first cleaning spray pipe 5a, the secondary cleaning spray pipe 7b, the three cleaning spray pipe 8b, and the four cleaning spray pipe 9d are not shown in the drawing.

[0023] The closed continuous bamboo shoots cooking box 3 includes a closed box body 3b with a top cover 3a, a cooking conveying chain plate 3c arranged in the box body, a steam pipeline 3d for delivering steam to the box body, a water inlet pipe 3e and a water outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com