Tea stir-frying device capable of controlling temperature

A technology for controlling temperature and frying tea, which is applied in the field of temperature-controllable tea-frying devices, which can solve problems such as poor production quality stability, low efficiency, and high labor intensity, and achieve the effect of improving quality, improving efficiency, and ensuring rapid dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

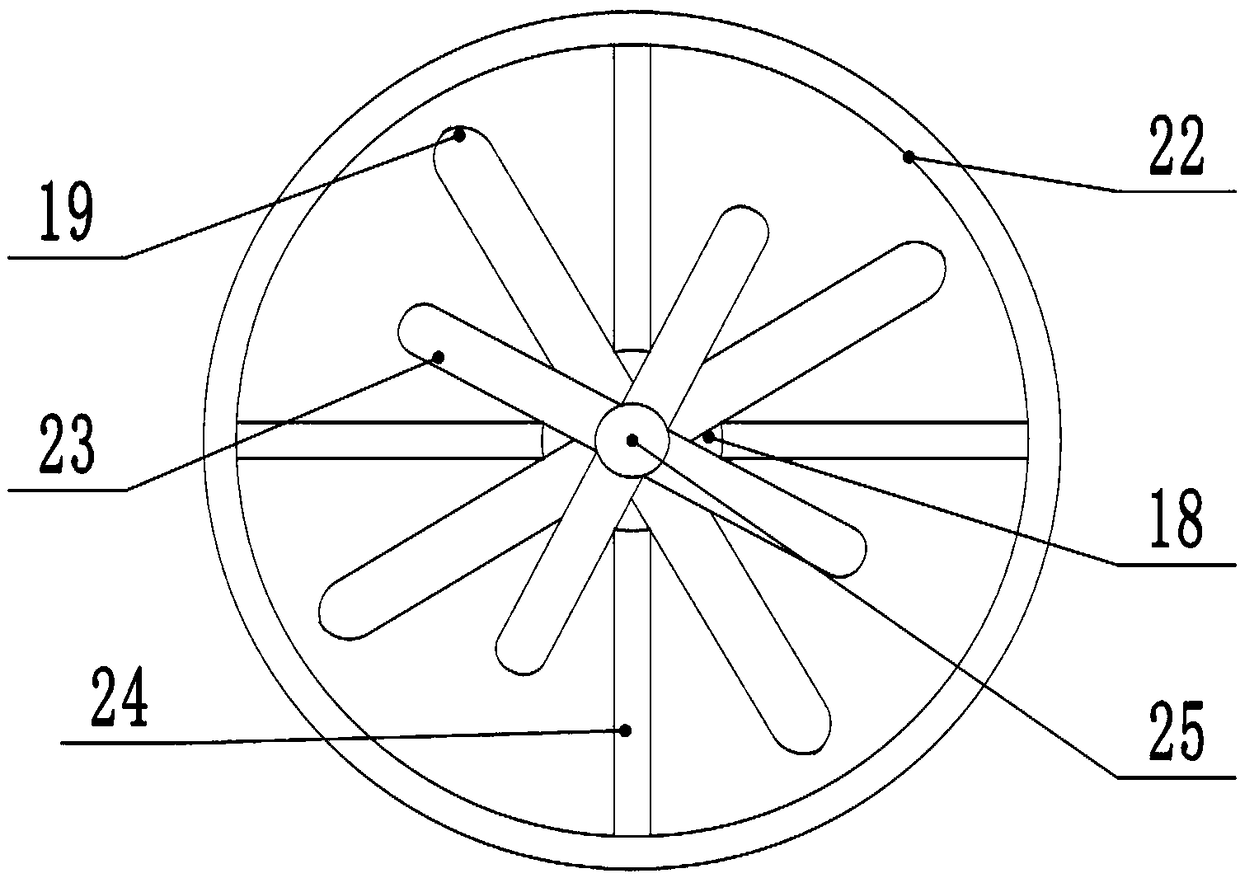

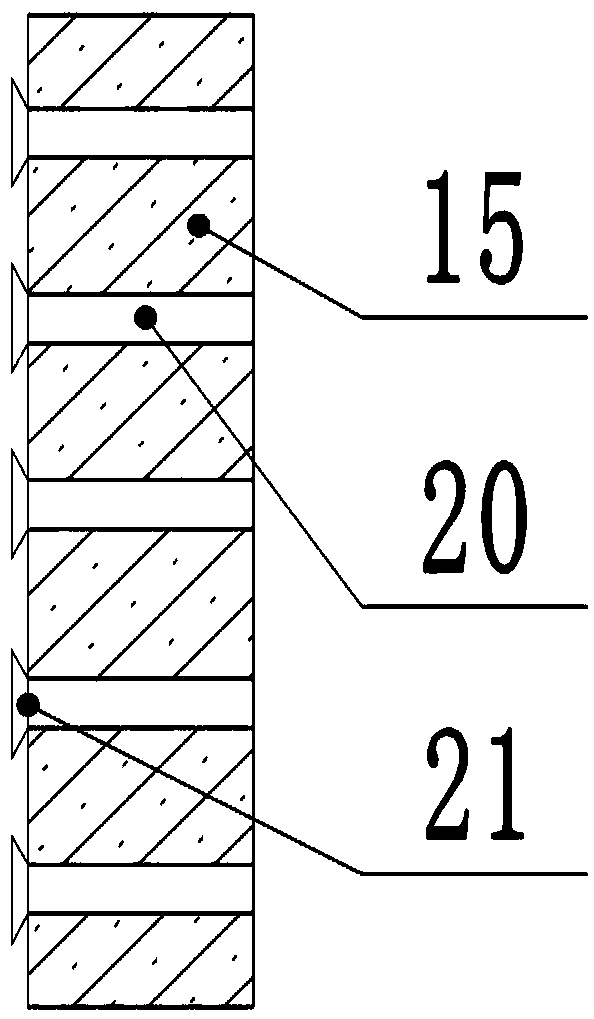

[0022] see figure 1 , a temperature-controllable tea-frying device, comprising: a column 1, a foot 2, a tie rod 3, a tea-frying machine shell 4, a tea-frying bowl 15, a middle support frame 16, and a hopper 22, and the column 1 is fixedly installed Above the ground, the lower end of the column 1 is provided with an anchor 2, and the anchor 2 is made of rubber shock-absorbing and non-slip, which can effectively reduce the noise generated by the vibration. The middle of the column 1 is provided with a tie rod 3, and the tie rod 3 is an aluminum alloy steel pipe, which can effectively improve the ability of the device to resist the impact of radial loads, thereby improving the stability of the device. The upper end of the column 1 is welded with a tea frying machine shell 4, and the tea frying machine shell 4 is stainless steel The tank body has a feeding port on the top, and a feeding hopper 22 is arranged at the upper end of the shell 4 of the tea frying machine. The lower end ...

Embodiment 2

[0025]Further, the second rotating shaft 10 is made of high manganese alloy steel material after heat treatment to improve the toughness of the material, and the surface is shot peened to increase surface hardness and reduce roughness, thereby improving wear resistance and corrosion resistance.

Embodiment 3

[0027] Preferably, the heater 14 is also in the shape of an inverted arch, with a heating block inlaid inside, which changes the disadvantages of traditional bottom heating, and can simultaneously heat the bottom and the side, improving efficiency and ensuring uniform heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com