Tunnel type intelligent vegetable planting machine

A smart planting and tunnel-type technology, applied in planting methods, transplanting machinery, applications, etc., can solve problems such as the inability to realize the combination of technology and nature, high planting costs, and waste of water resources, so as to increase vegetable output and increase Effects of safety and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

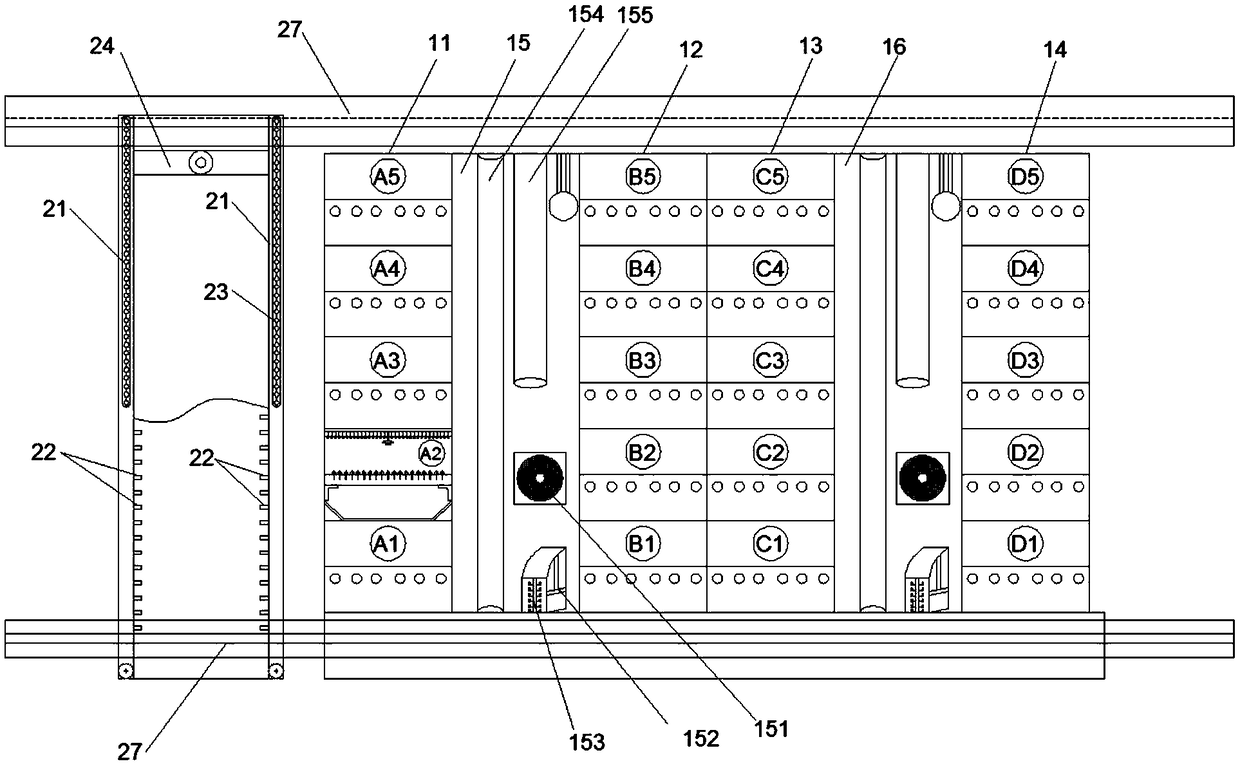

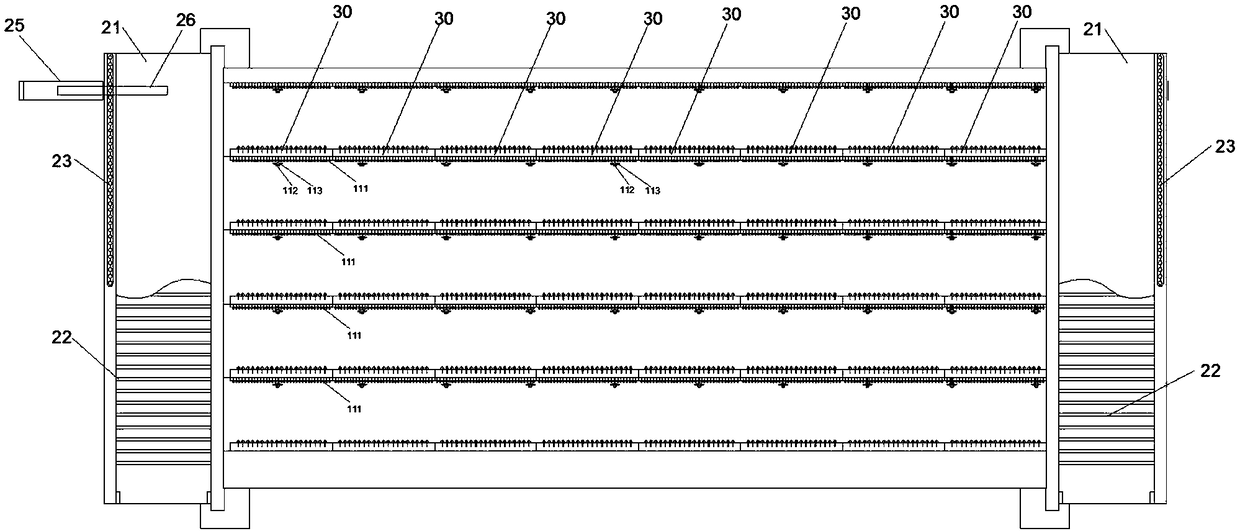

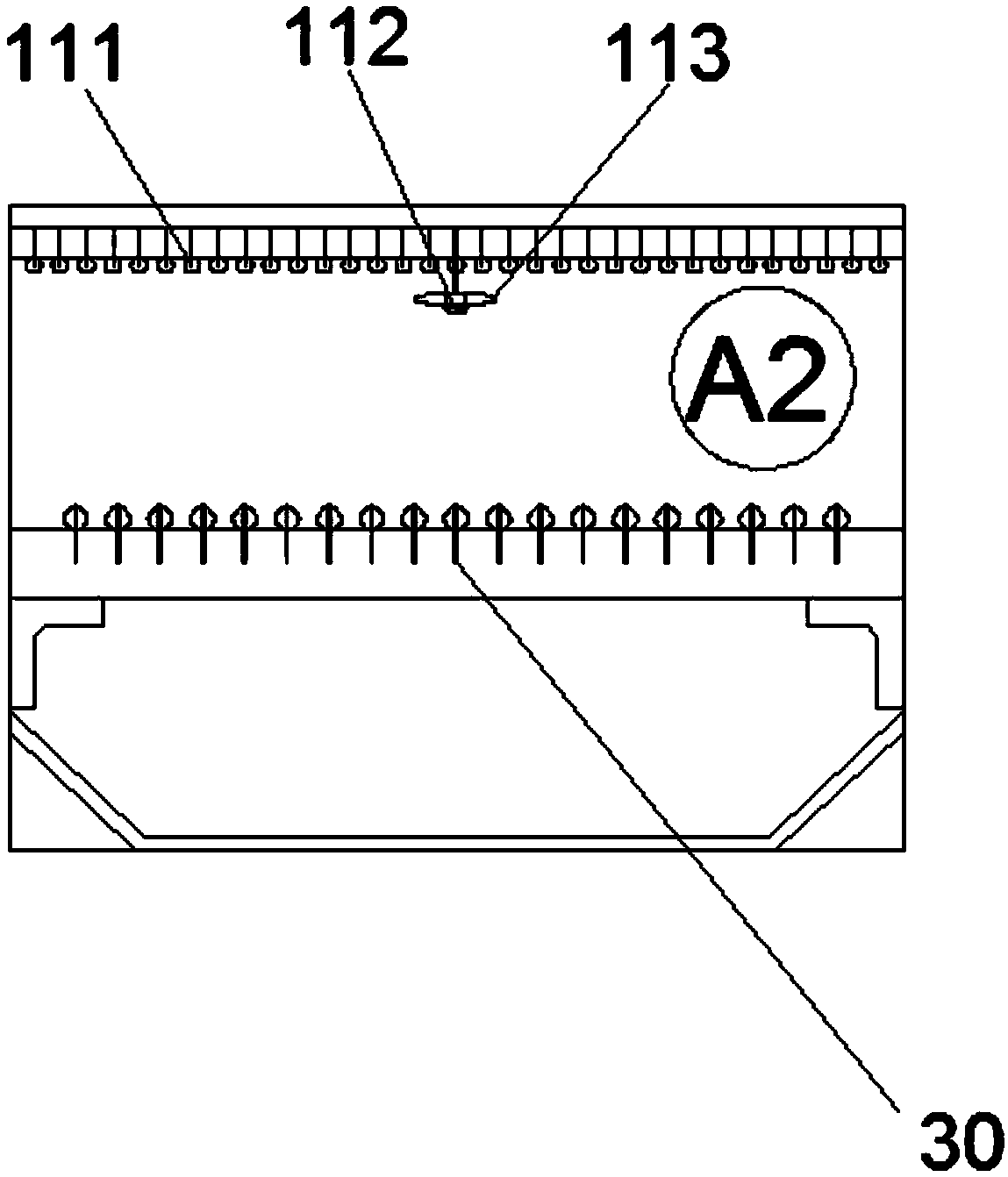

[0026] The present invention will be further described below in conjunction with specific drawings.

[0027] Such as Figure 1-3 As shown, a tunnel-type vegetable planting machine is provided, including 4 rows of planting rooms, numbered respectively as row A planting room 11, B column planting room 12, C column planting room 13 and D column planting room 14, and each row of planting rooms is set There are 5 small cuboid planting chambers, numbered from bottom to top according to Xy, where X=column number; y=row number. which is:

[0028] A row of rectangular parallelepiped small planting chambers includes from bottom to top: A1-A5;

[0029] The small cuboid planting chambers in row B include from bottom to top: B1-B5;

[0030] The cuboid-shaped small planting chambers in column C include: C1-C5 from bottom to top;

[0031] The small cuboid planting chambers in row D include from bottom to top: D1-D5;

[0032] For the convenience of description, the cuboid-shaped planting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com