Preparation method of n and s double-doped graphene-graphene nanoribbon aerogels

A graphene nanobelt and graphene technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of effective specific surface area loss, reduce specific capacitance, etc., achieve enhanced reactivity and conductivity, and improve electrical conductivity performance, improve the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

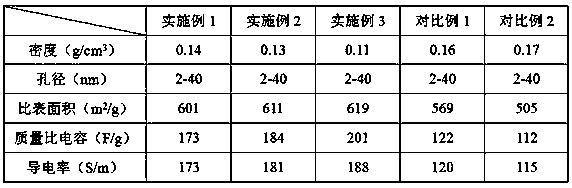

Examples

preparation example Construction

[0021] Preparation of graphene oxide nanoribbons:

[0022] (A) In 36 mL of concentrated H 2 SO 4 0.15 g of multi-walled carbon nanotubes (MWCNTs) was added to the solution, and after magnetic stirring for 2 h, 4 mL of H 3 PO 4 , continue stirring for 15 min; add 1.2 g KMnO 4 Then, it was transferred to an oil bath at 65 °C and stirred for 2 h. After the reaction was completed and cooled to room temperature, 100 mL of ice water (containing 5 mL of 30% H 2 o 2 ), let stand for 14 h;

[0023] (B) After standing still, pour off the supernatant, filter the remaining solution with a 220 µm microporous membrane, wash twice with 6 mL of 20% HCl; redisperse the solid obtained by suction in a 60 mL ultra Stir in pure water for 2 h and then sonicate to obtain a uniformly dispersed solution, which is added to 40 mL of 30% HCl and allowed to stand for 14 h;

[0024] (C) Suction filter with the same filter membrane and redisperse the obtained product in 40 mL of anhydrous methanol a...

Embodiment 1

[0027] A preparation method of N and S double-doped graphene-graphene nanoribbon airgel, specifically comprising the following steps:

[0028] (1) Preparation of graphene oxide nanobelts;

[0029] (2) Preparation of graphene oxide;

[0030] (3) Mix 50 mg of graphene oxide nanoribbons prepared in step (1) with 50 mg of graphene oxide prepared in step (2), add 50 mL of deionized water, and obtain a mixed solution with a concentration of 2 mg / mL after ultrasonication ;

[0031] (4) Add 0.5 mg of pyrrole and 0.5 mg of thiophene to the mixture obtained in step (3), and conduct a hydrothermal reaction at a reaction temperature of 165°C for 5 hours to obtain a hydrogel;

[0032] (5) Put the hydrogel obtained in step (4) into 2M KNO 3 In the solution, a second hydrothermal reaction is carried out, the reaction temperature is 120°C, the reaction time is 3h, after cooling to room temperature, it is filtered, washed and freeze-dried;

[0033] (6) The product obtained after freeze-dry...

Embodiment 2

[0035] A preparation method of N and S double-doped graphene-graphene nanoribbon airgel, specifically comprising the following steps:

[0036] (1) Preparation of graphene oxide nanobelts;

[0037] (2) Preparation of graphene oxide;

[0038] (3) Mix 50 mg of graphene oxide nanoribbons prepared in step (1) with 50 mg of graphene oxide prepared in step (2), add 50 mL of deionized water, and obtain a mixed solution with a concentration of 2 mg / mL after ultrasonication ;

[0039] (4) Add 0.5 mg of pyrrole and 0.5 mg of thiophene to the mixture obtained in step (3), and conduct a hydrothermal reaction at a reaction temperature of 180°C for 3 hours to obtain a hydrogel;

[0040] (5) Put the hydrogel obtained in step (4) into 2M KNO 3 In the solution, a second hydrothermal reaction is carried out, the reaction temperature is 130°C, and the reaction time is 2h. After cooling to room temperature, it is filtered, washed and freeze-dried;

[0041] (6) The product obtained after freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com