Haptic feedback device

A tactile feedback, initial position technology, applied in the direction of instrument, electrical digital data processing, user/computer interaction input/output, etc., can solve the problems of complex production process, slow response speed, large energy loss, etc., to achieve the transmission effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

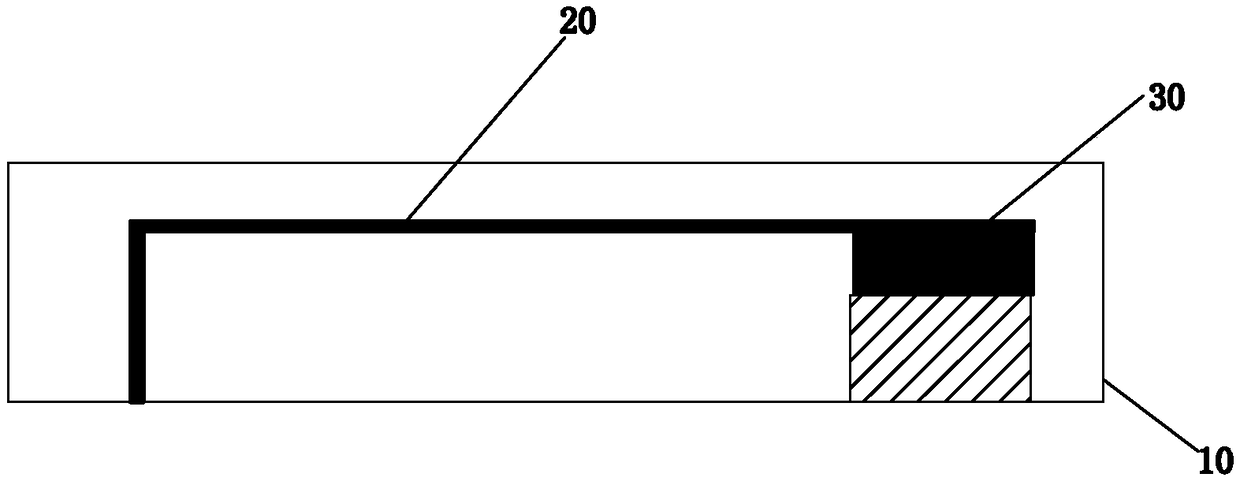

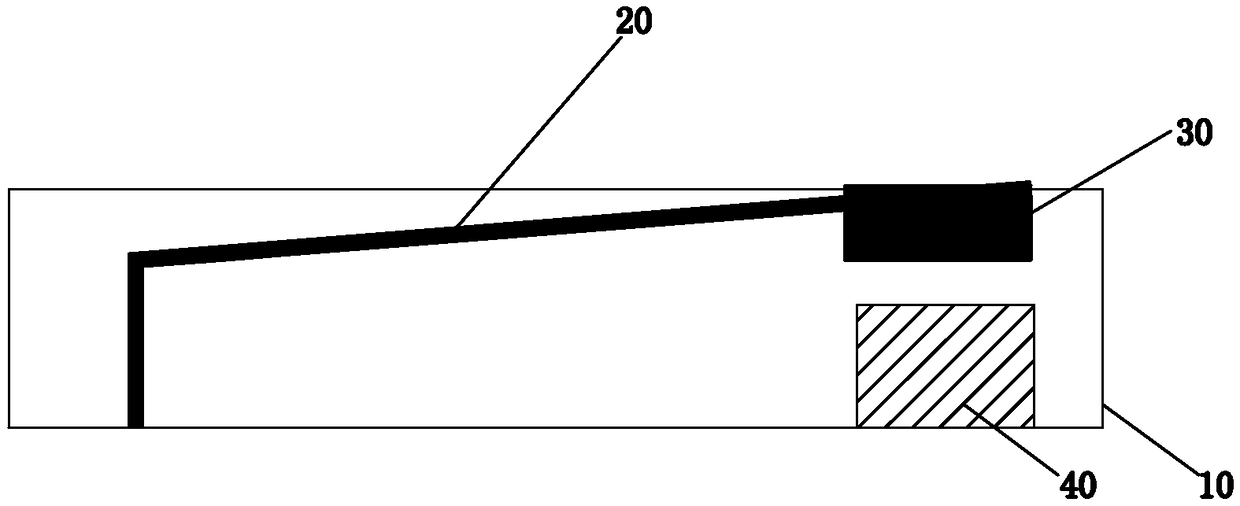

[0019] Please check Figure 1 to Figure 2 , a preferred embodiment of the tactile feedback device, the tactile feedback device includes a housing 10 , an elastic substrate 20 , a mass 30 and a laminated piezoelectric ceramic 40 .

[0020] The casing 10 has a rectangular shape.

[0021] The laminated piezoelectric ceramics 40 are fixed on the inner bottom surface of the casing 10 . In this embodiment, the laminated piezoelectric ceramic 40 is in the shape of a square.

[0022] In this embodiment, the laminated piezoelectric ceramic 40 is fixed to the inner bottom surface of the housing 10 by glue bonding or fitting or pressing.

[0023] The mass block 30 is affixed to one end of the elastic substrate 20 and moves between the initial position and the impact position, the other end of the elastic substrate 20 is affixed in the housing 10, and the mass block 30 abuts against the stacked On the top surface of the piezoelectric ceramic 40, the laminated piezoelectric ceramic 40 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com