Energy-saving low-noise gas steaming furnace

A low-noise, gas-fired technology, applied in the field of energy-saving and low-noise gas steam ovens, can solve problems such as noise, low heating efficiency, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

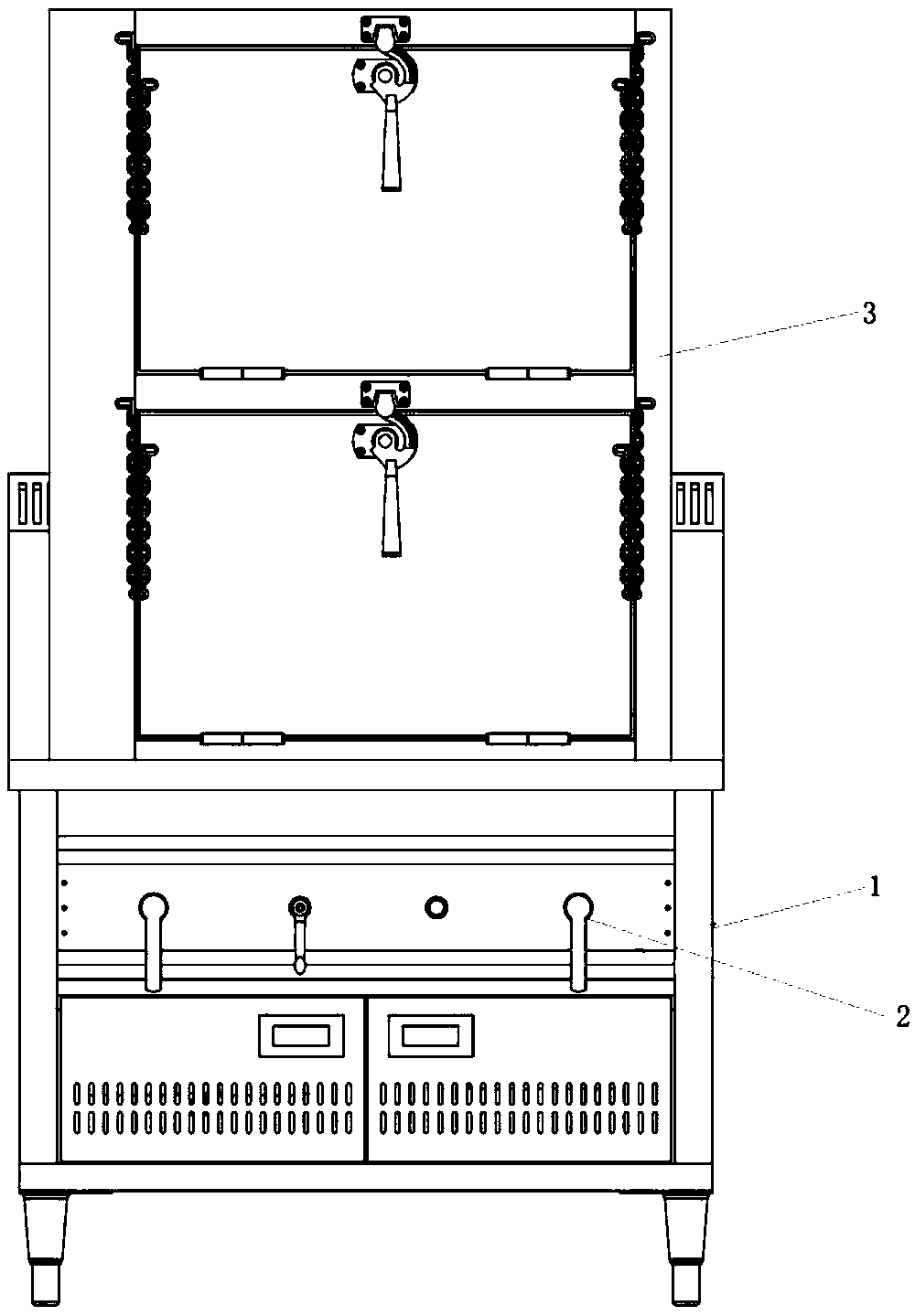

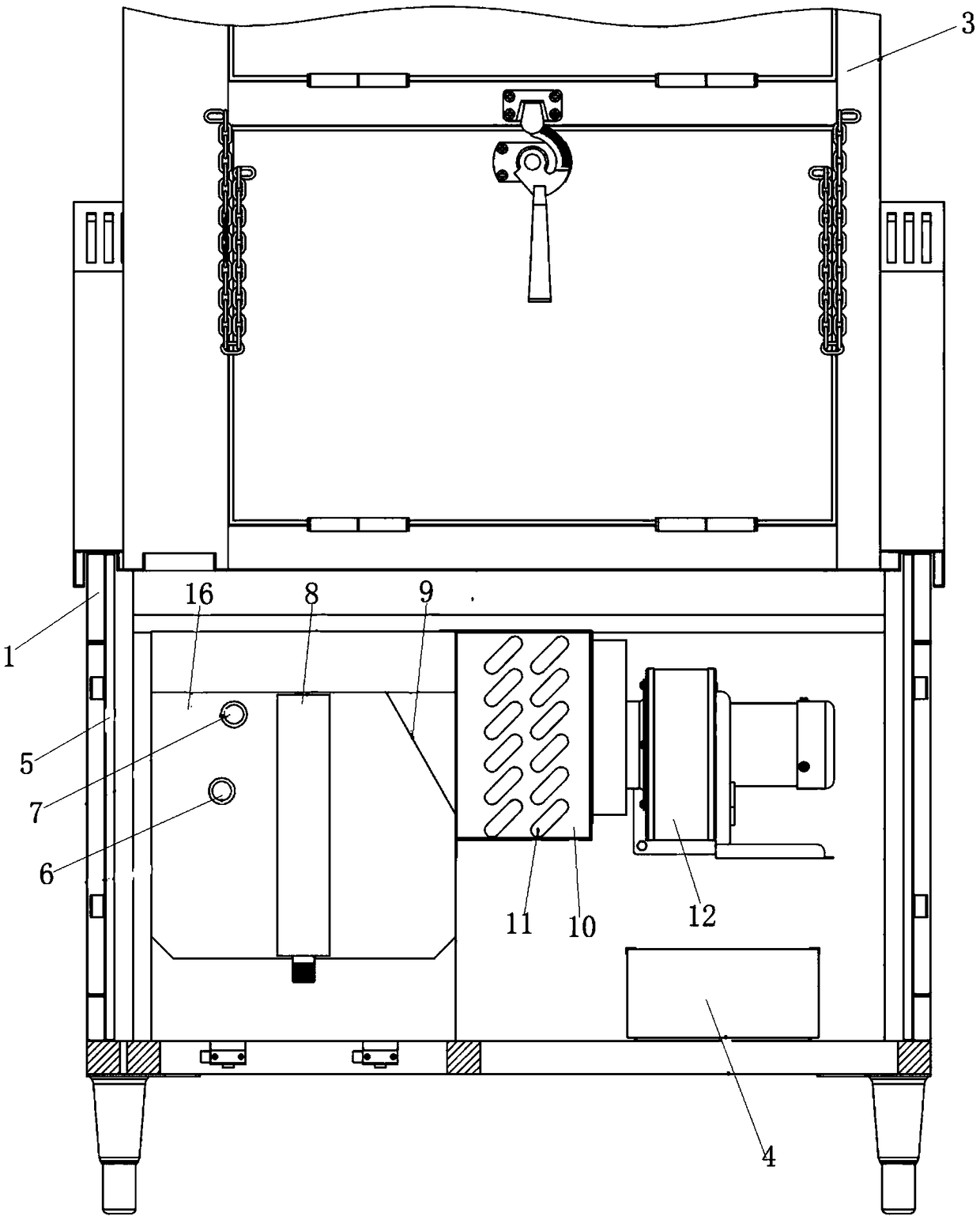

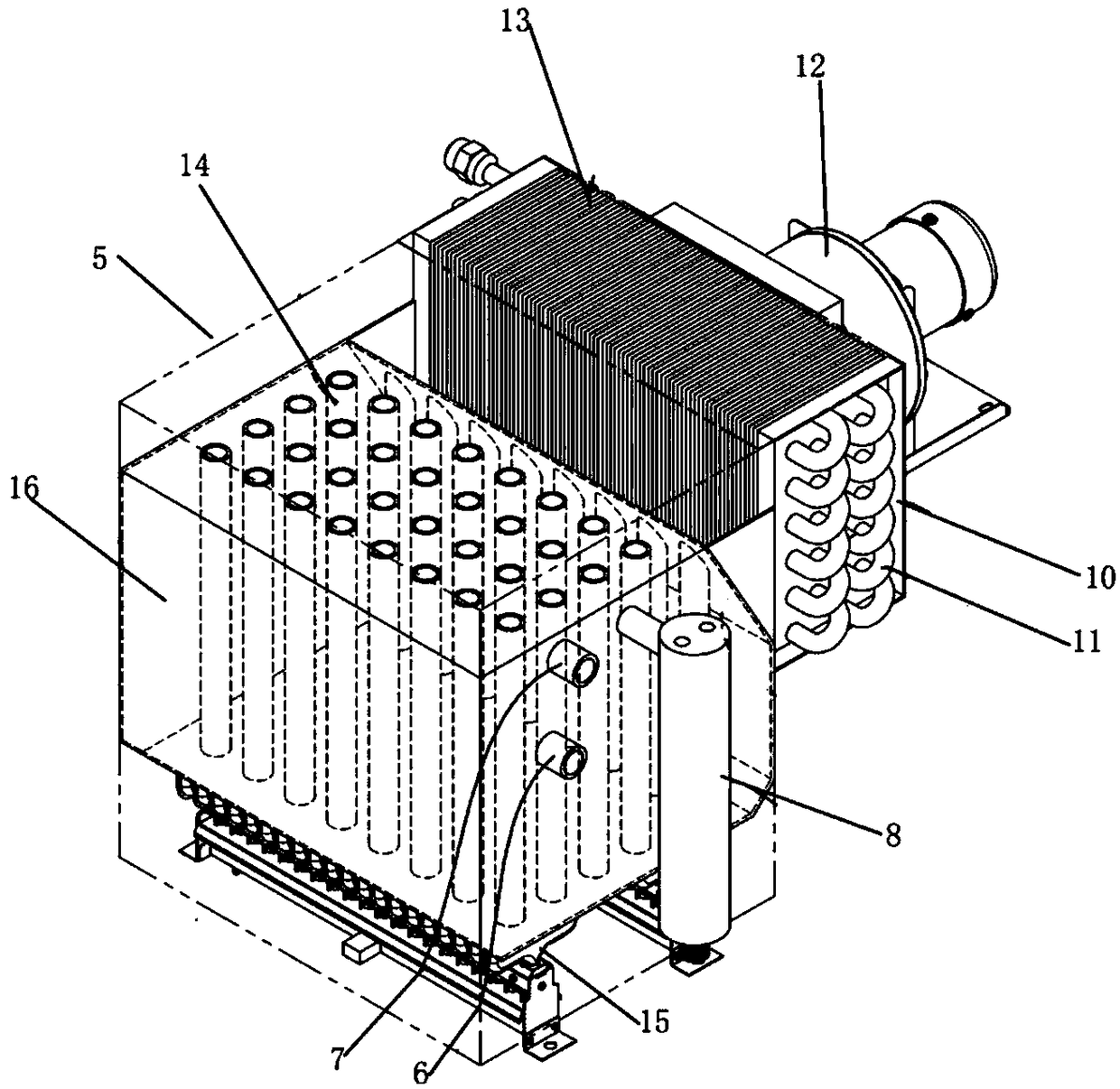

[0019] Such as figure 1 and figure 2 As shown, the present invention is an energy-saving and low-noise gas stove. The gas steam oven includes a furnace body, a heating unit 20, a recovery unit 30 and an alarm device. The furnace body comprises a hollow furnace base 1, a control part 2, a power supply box 4 and a steam box 3, the control part 2 is arranged on the side of the furnace base 1, and the power supply box 4 is arranged in the inside of the furnace base 1 and is connected with the furnace base 1. The control part 2 is electrically connected, the steam box 3 is arranged on the top of the furnace base 1 and communicates with the inside of the furnace base 1, the alarm device includes a pipeline, and the pipeline is provided with a valve, and finally passes through the The pipes are connected to the gas steamer.

[0020] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com