Dedusting cotton fluffing device

A technology of plucking cotton and purification devices, which is applied in transportation and packaging, disperse particle filtration, textiles and papermaking, etc. It can solve problems such as dust generation and impact on the working environment, achieve removal of peculiar smell and dust, protect the working environment, and increase cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

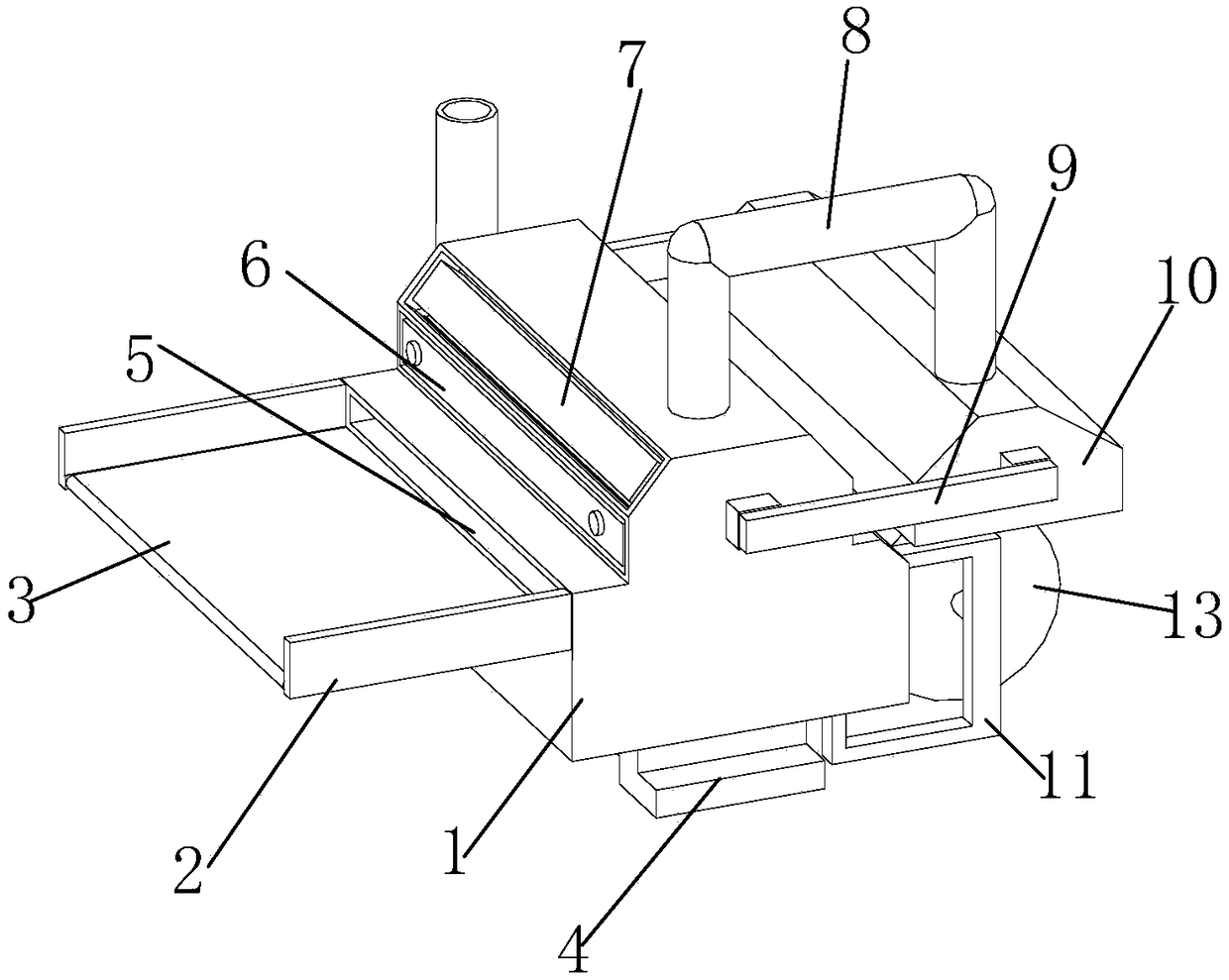

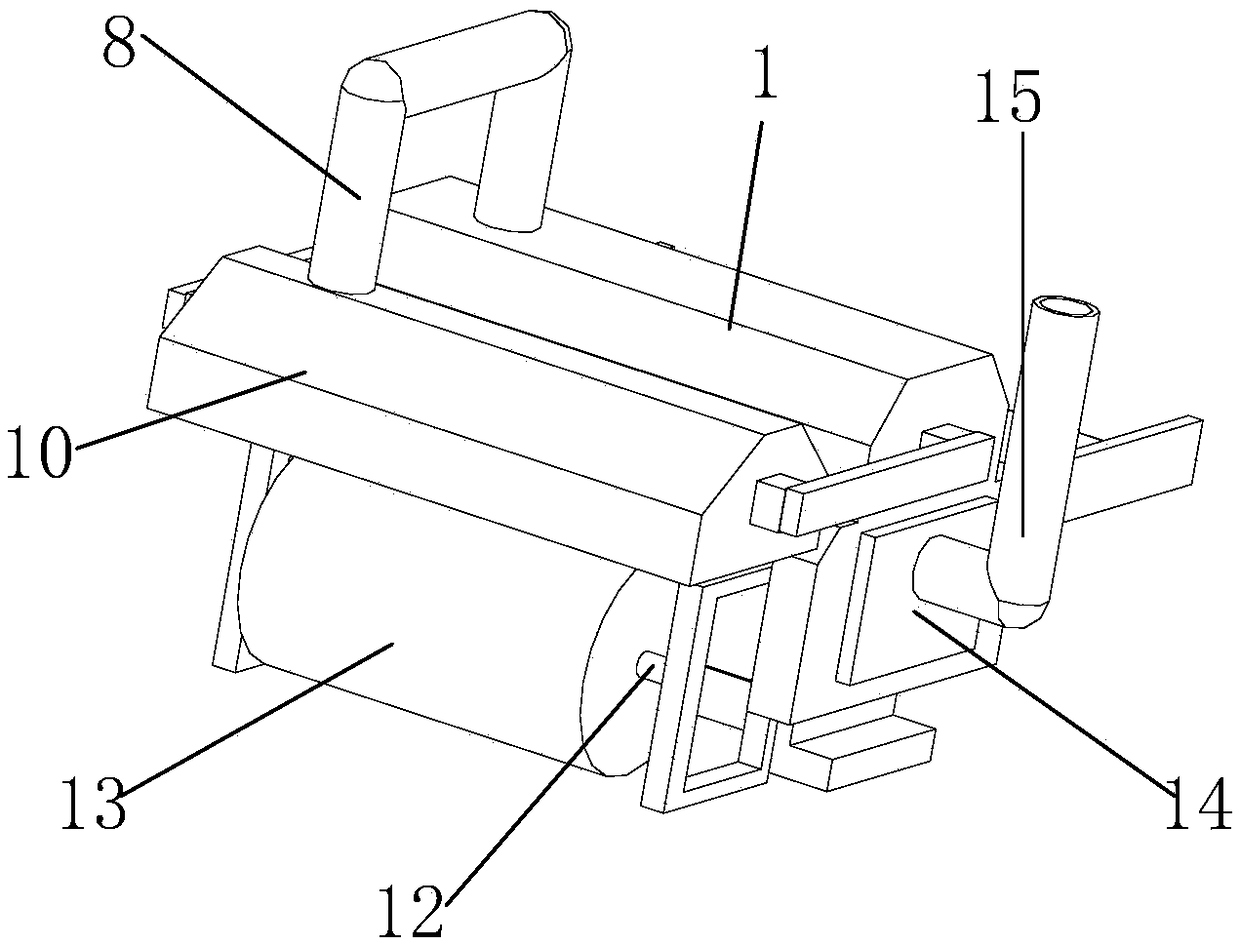

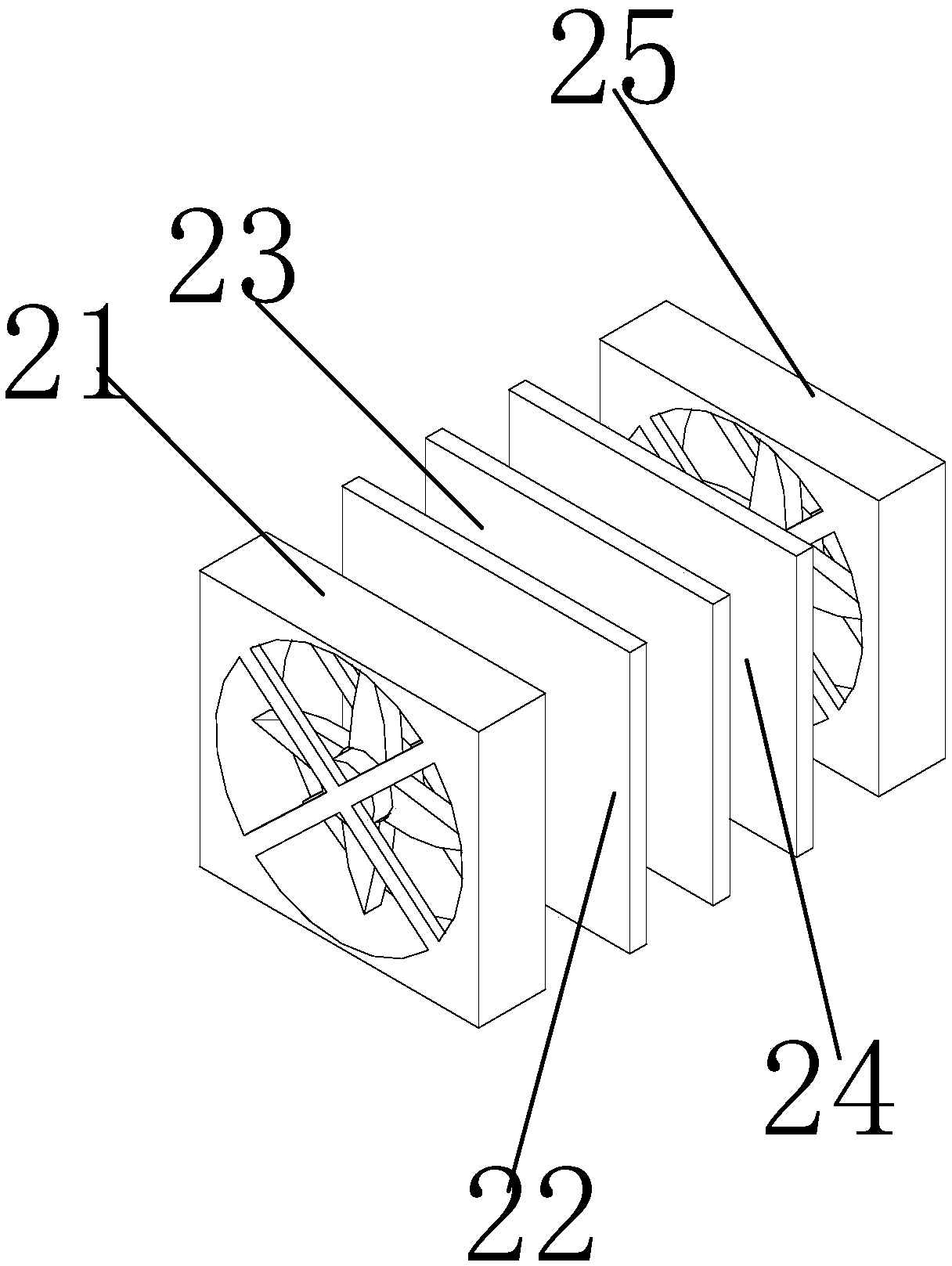

[0017] like Figure 1 to Figure 4 As shown, the present invention includes a frame 1, a baffle plate 2, a transmission belt 3, a base 4, a dust collection box 6, a filter device 7, a transmission pipe 8, a connecting seat 9, a vacuum cleaner 10, a support seat 11, and a roller Shaft 12, cotton suction dust cage 13, purification device 14, exhaust pipe 15, base 4 is installed at the bottom of frame 1, baffle plate 2 and transmission belt 3 are connected to one side of frame 1, baffle plate 2 and transmission belt 3 connected, the dust collection box 6 and the filter device 7 are all installed inside the frame 1, the dust collection box 6 is located on the lower side of the filter device 7, the transmission pipe 8, the connection seat 9, and the support seat 11 are all connected to the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com