Preparation method of fine particle NTO

A fine particle, dissolving liquid technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, organic chemistry, etc., can solve the problems of complex process and wide range of NTO crystal particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of fine particle NTO, comprises the following steps:

[0024] Add the solution of raw material NTO dropwise into cold water under stirring condition, and filter the obtained mixed material liquid to obtain fine particle NTO;

[0025] The solvent of the dissolving liquid is nitrogen methyl pyrrolidone; the temperature of the dissolving liquid is 60-80° C.; the temperature of the cold water is 0-5° C.; the stirring rate is 300-500 r / min.

[0026] In the present invention, the solution solution of raw material NTO is added dropwise into cold water under stirring condition, and the obtained mixed material solution is filtered to obtain fine particle NTO. In the present invention, the solvent of the dissolving solution is nitrogen-methylpyrrolidone; the volume ratio of the nitrogen-methylpyrrolidone and cold water is preferably 1:5-8, more preferably 1:7-8; The mass percent concentration of the raw material NTO is preferab...

Embodiment 1

[0033] Dissolve 1000 g of NTO raw material in 1.8 L of nitrogen methyl pyrrolidone, and the temperature of the constant temperature water bath is 80 ° C. Add 14L of pure water into the crystallizer, start stirring, the stirring speed is 400r / min, turn on the refrigeration cycle, so that the temperature of the pure water in the crystallizer drops to 0°C, and use a constant pressure dropping funnel to drop the solution to control the temperature in the crystallizer The temperature is 0-5°C, and the dropwise addition time is 5 minutes. After the dropwise addition is completed, filter and dry to obtain fine particles of NTO.

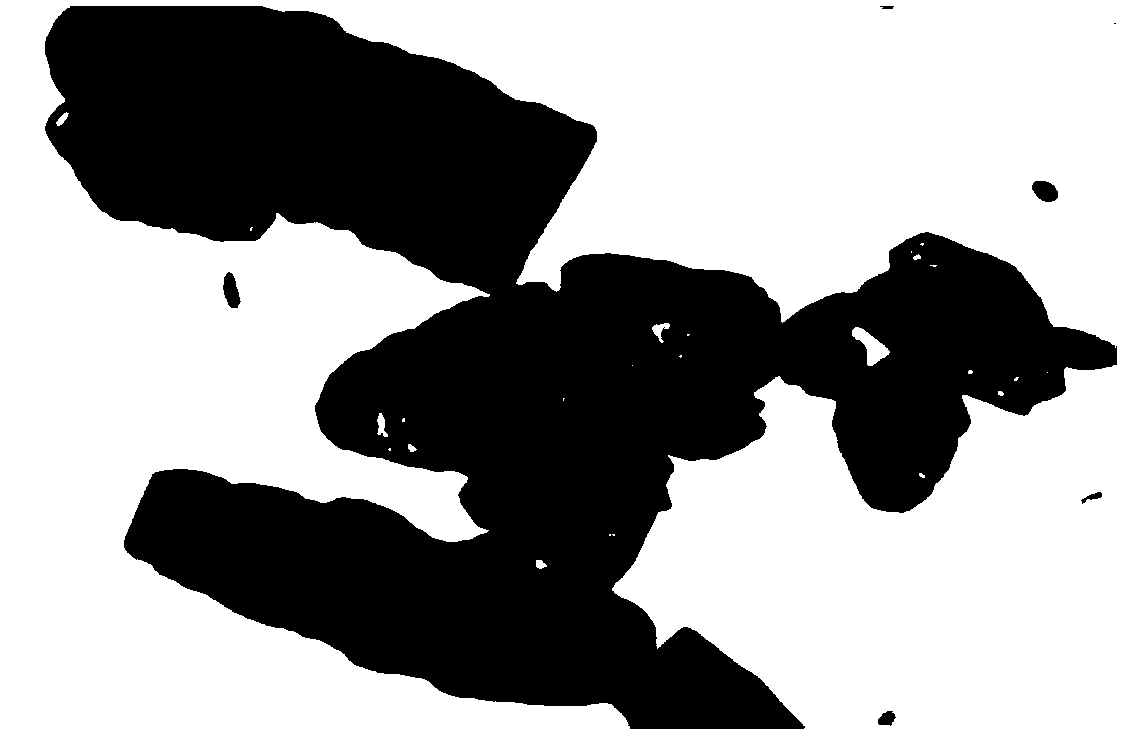

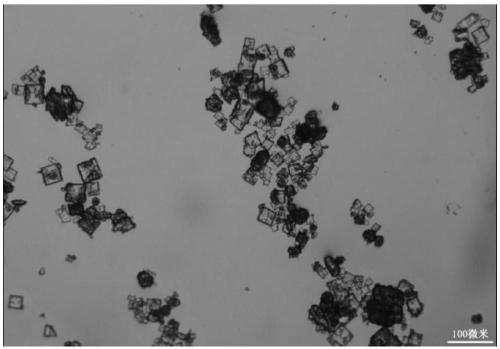

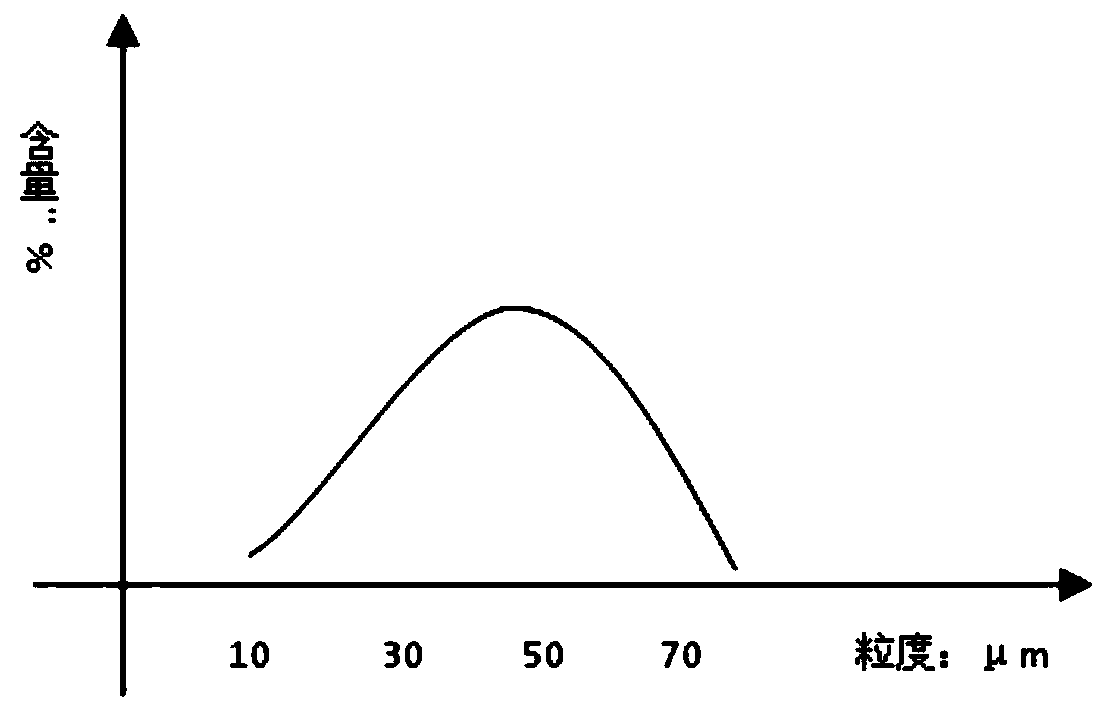

[0034] Carry out electron microscope test to the NTO raw material of embodiment 1 and the fine particle NTO that obtains, test result is as follows figure 1 and figure 2 shown. figure 1 is the electron microscope picture of the NTO raw material, figure 2 Electron microscope image of fine-grained NTO. figure 1 The results show that before crystalliza...

Embodiment 2

[0037] Dissolve 1000g of NTO raw material in 1.8L of nitrogen methyl pyrrolidone, and the temperature of the constant temperature water bath is 70°C. Add 14L of pure water to the crystallizer, start stirring, the stirring speed is 500r / min, turn on the refrigeration cycle, so that the temperature of the pure water in the crystallizer drops to 3°C, use a constant pressure dropping funnel to drop the solution to control the temperature in the crystallizer The temperature is 0-5°C, and the dropwise addition time is 15 minutes. After the dropwise addition is completed, filter and dry to obtain fine particles of NTO.

[0038] The fine-grained NTO obtained in Example 2 was subjected to an electron microscope test, and the test result was similar to the electron microscope image of the fine-grained NTO obtained in Example 1. The NTO after crystallization was a flaky crystal with a narrow particle size range, an average of 30 μm, and The crystal shape is relatively regular and the uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com