Oil pressure buffer

A technology of oil pressure buffer and cylinder block, which is applied in the field of oil pressure buffer, can solve the problems of increasing the gap between the throttle ring and the throttle cone rod, long oil pressure time, etc., to increase the oil inlet rate and oil refueling speed Improve and increase the effect of oil intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

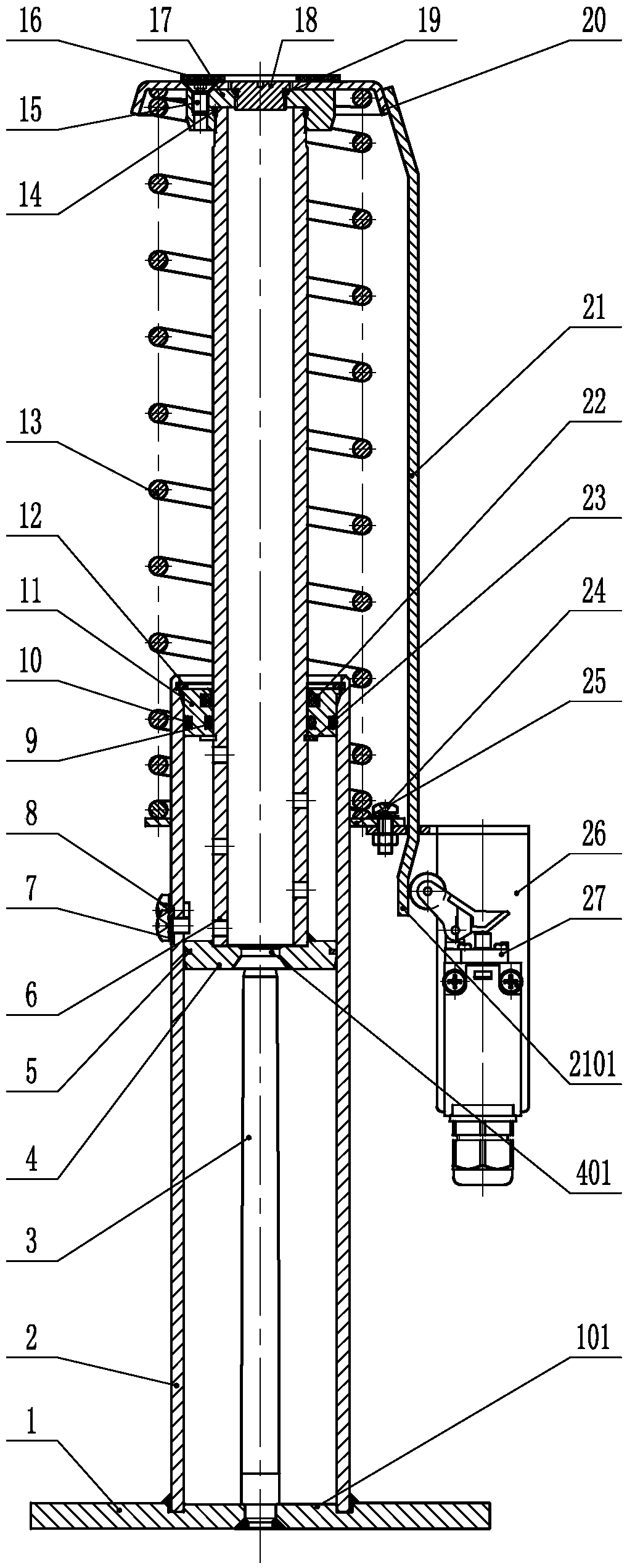

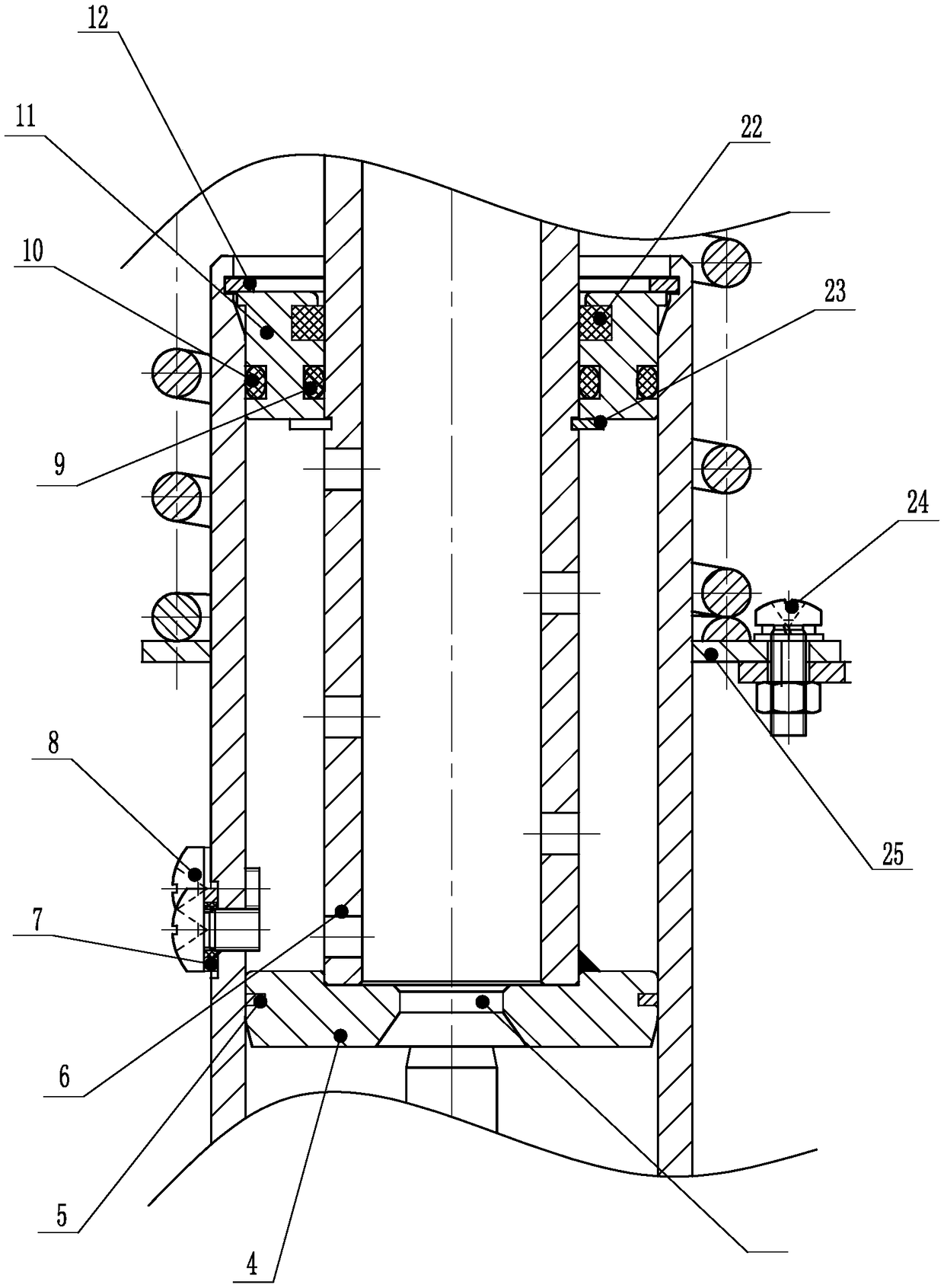

[0032] A high-tightness oil pressure buffer provided in this embodiment has a structure such as Figure 1-3 As shown, including cylinder 2, piston 4, and piston rod 6, the side of piston 4 in contact with cylinder 2 is provided with an annular groove, and a piston ring 5 is embedded in the annular groove. It is tightly attached to the inner wall of the cylinder body 2 and is in a sealed state, and the piston 4 and the piston rod 6 are fixedly connected by spot welding.

[0033] The piston 4 is provided with an inclined surface near the bottom edge, and the inclined surface and the inner wall of the cylinder body 2 form a pre-lubrication space, and the piston ring 5 is located in the center between the highest point of the inclined surface and the highest point of the piston 4 .

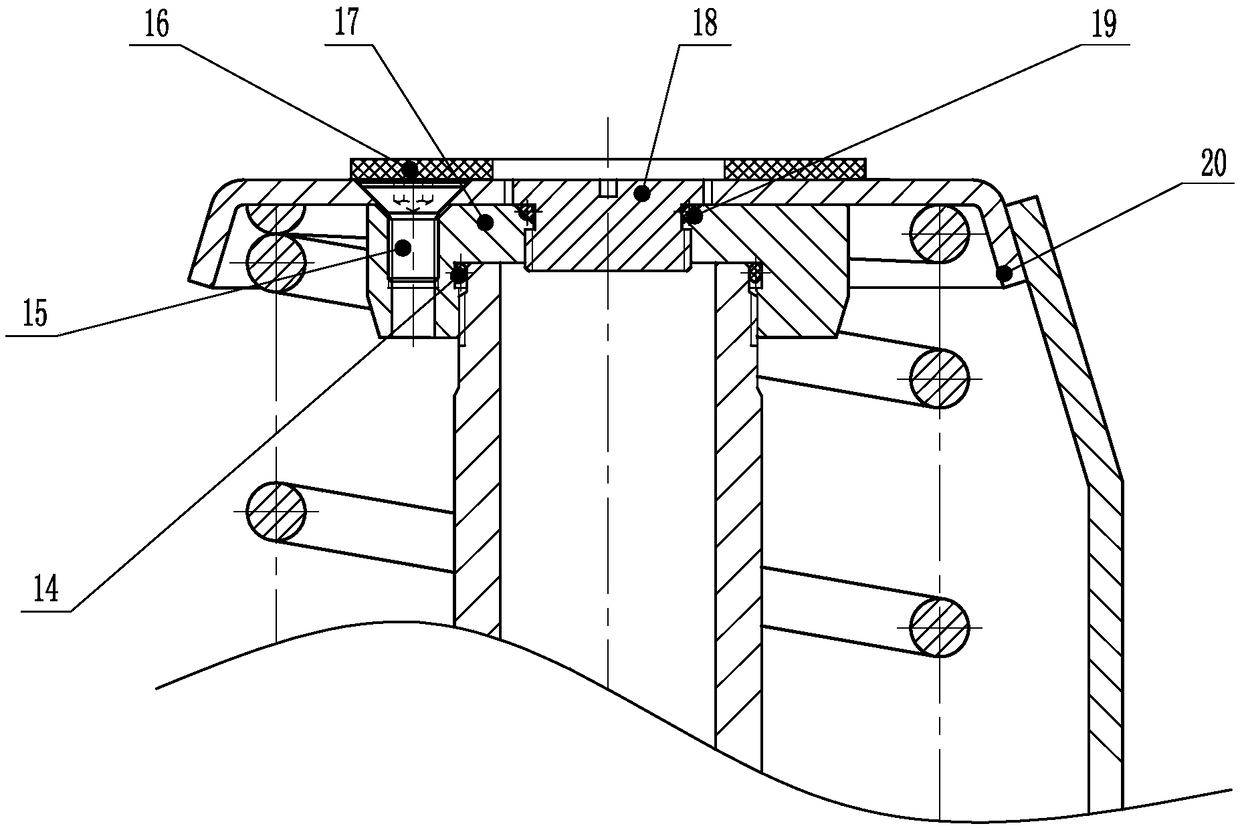

[0034] It also includes a buffer plate 16, an end cover 17, a sealing screw plug 18, an upper spring seat 20, a lower spring seat 25 and a compression spring 13. The end cover 17 is wrapped on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com