Component hydroforming springback accurate compensation method based on liquid volume control

A liquid volume, hydroforming technology, applied in the field of accurate springback compensation of metal plate components, can solve the problem of inability to solve different batches, the accuracy of the part profile cannot be accurately controlled, and the performance changes of the plate cannot be compensated online and in-situ for springback, etc. problems, to achieve the effect of shortening the mold debugging cycle, shortening the debugging cycle and improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0053] Specific implementation mode one: this implementation mode is realized through the following steps:

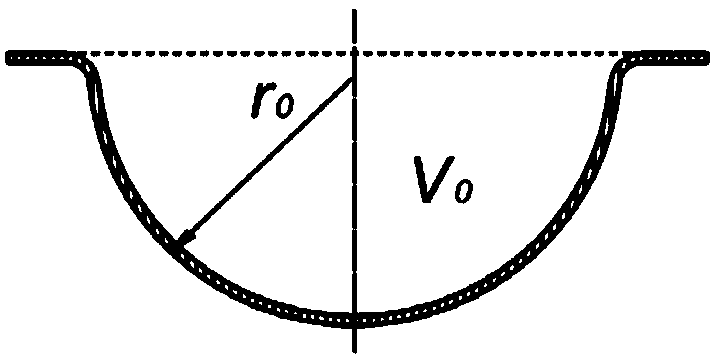

[0054] Step 1: Calculate the theoretical volume V of the corresponding surface according to the design surface of the curved panel 0 ;

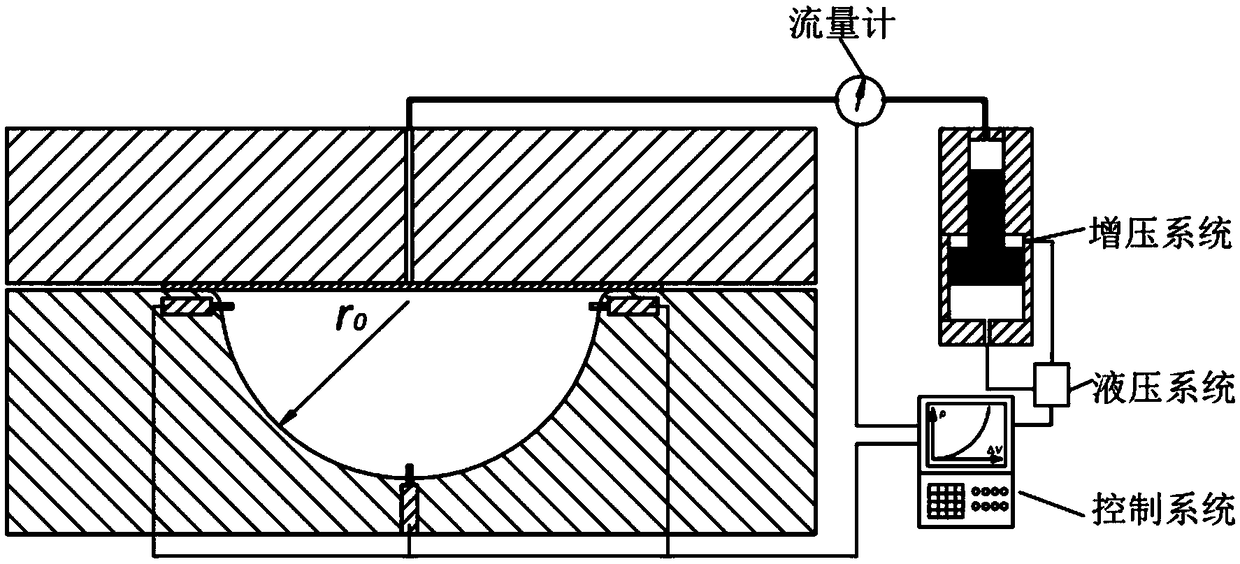

[0055] Step 2: Put the slab into the mold and close the mold, fill the mold with liquid water and pressurize it through an external pressurization system, so that the slab starts to be formed by liquid punch under the action of liquid pressure;

[0056] Step 3: Use a flowmeter to record the change of the liquid flow rate filled into the mold. When the volume of liquid filled into the mold reaches V 0 When the liquid filling and unloading are stopped through the control system;

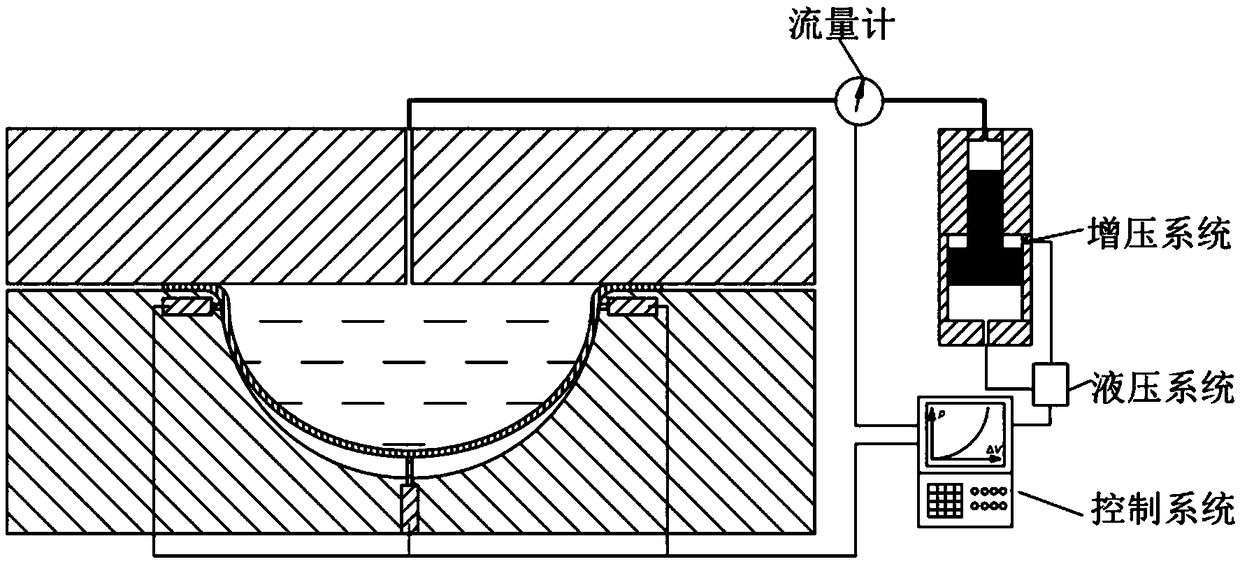

[0057] Step 4: Use the displacement sensor to measure the distance between the unloaded part surface and the corresponding mold surface on-line, calculate the measured volume V of the unloaded part, and calculate V 0 The volume difference with V is △V;

[0...

specific Embodiment approach 2

[0060] Considering the overall process of ultra-high pressure, in order to avoid the error caused by the volume compression of the liquid under ultra-high pressure and affect the precise control of the liquid volume, on the basis of steps 1 to 5 of the specific embodiment 1, this embodiment also includes the following steps :

[0061] Step 6: According to the liquid volume compression △V p Relational formula △V with liquid pressure p p =β·p·V, calculate the volume of liquid filled into the mold as (V 0 +△V) when the liquid volume compression △V p =β·p·(V 0 +△V), where β is the compressibility coefficient of the liquid medium;

[0062] Step 7: Fill the mold with water and pressurize again to cause the mold to deform elastically. Use a flowmeter to record the change of the amount of water filled into the mold. When the volume of liquid filled into the mold reaches V 0 +△V+△V p When the liquid is filled, stop the liquid filling through the control system, and take out the c...

specific Embodiment approach 3

[0064] Considering that there are errors in mold surface processing, when the actual size of the mold cavity is smaller than the lower tolerance of the part size, the invention does not need to modify the mold to realize high-precision forming of curved plate components at one time. This implementation mode includes the following steps:

[0065] Step 1: Calculate the corresponding theoretical volume V according to the design surface of the curved panel and the measured surface of the mold cavity 0 and mold cavity volume V 1 , calculate V 0 with V 1 The volume difference ΔV 1 =V 0 -V 1 ;

[0066] Step 2: Put the slab into the mold and close the mold, fill the mold with water and pressurize it through an external pressurization system, so that the slab starts to be formed by liquid punch under the action of water pressure;

[0067] Step 3: Use a flowmeter to record the change in the amount of water filled into the mold. When the volume of liquid filled into the mold reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com