Double-machine linkage industrial machine vision automatic detection system

An industrial machine and automatic detection technology, applied in the direction of instruments, measuring devices, measuring instrument components, etc., to achieve the effect of improving detection efficiency, low cost, and long-term stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail now in conjunction with accompanying drawing.

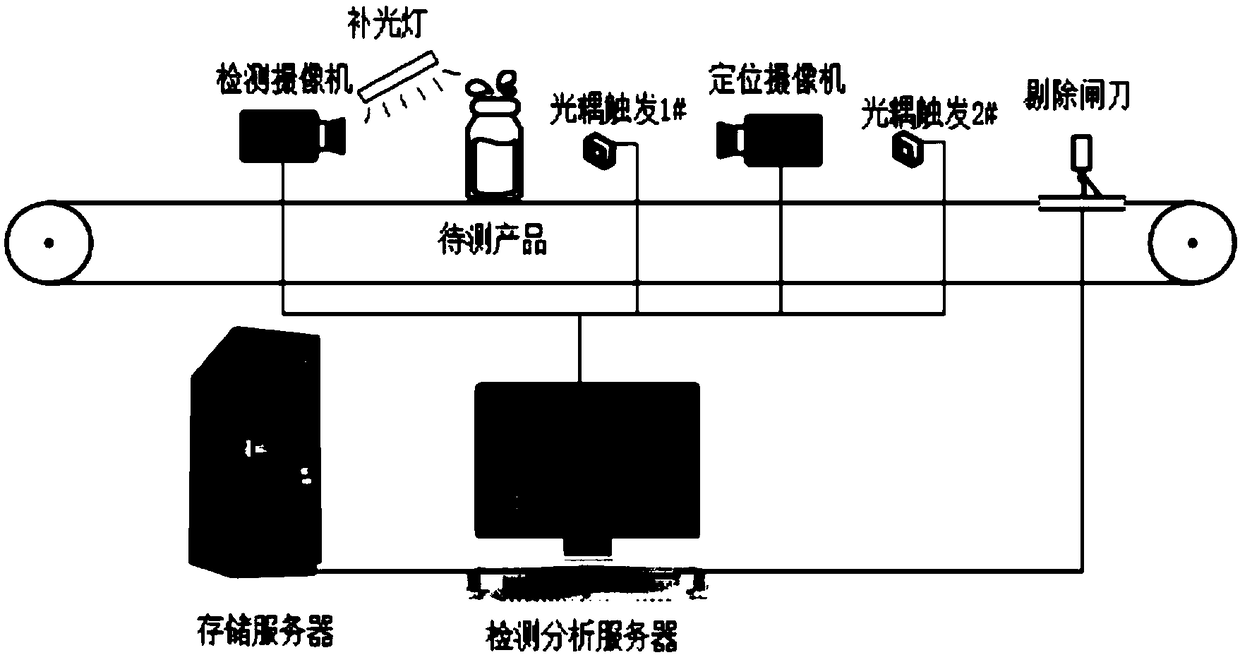

[0033] Such as figure 1 As shown, the main components of the dual-machine linkage industrial machine vision automatic detection system include:

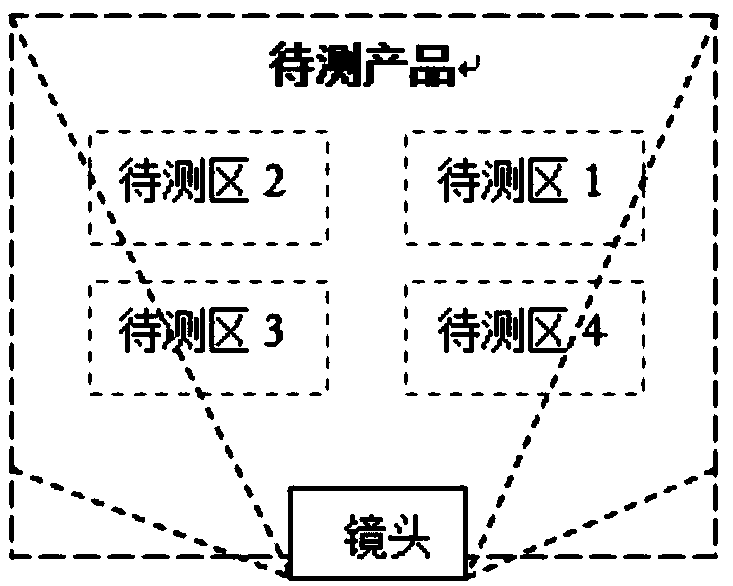

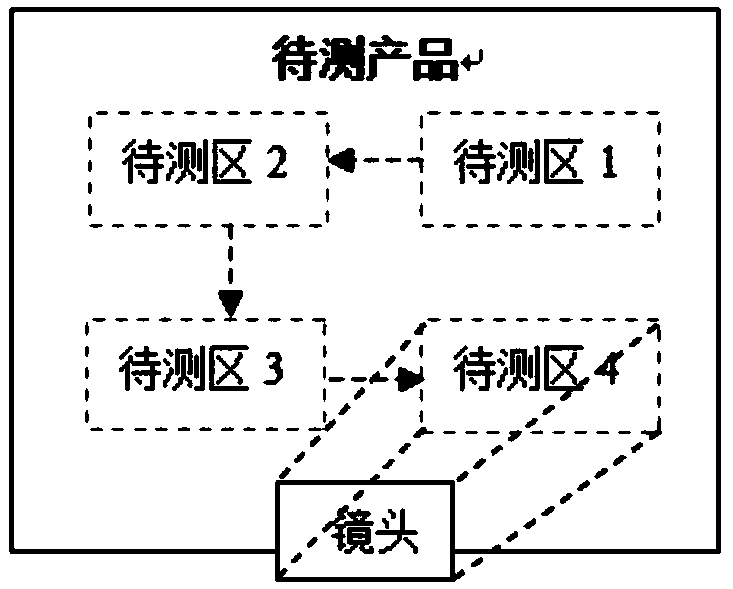

[0034] 1. Positioning camera: used to determine the area to be tested for large-volume and complex products to be tested, locate all the areas to be tested of the product to be tested from the acquired images, and upload the images to the detection and analysis server, and the server transmits the relevant positioning information For the detection camera, the detection camera collects and detects the images of all the areas to be tested one by one and uploads the images to the detection analysis server to realize the dual-machine linkage between the positioning camera and the detection camera. The viewing angle of the positioning camera is as follows: figure 2 shown.

[0035] 2. Detection camera: It forms a dual-machine link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com