Urea solution for vehicle and preparation method thereof

A technology of urea and solution for vehicles, which is applied in the field of urea solution for vehicles and its preparation, can solve the problems of low freezing point of urea solution for vehicles, incomplete decomposition of urea, good dispersibility, etc., and achieve surface activity enhancement, condensation reaction inhibition, The effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

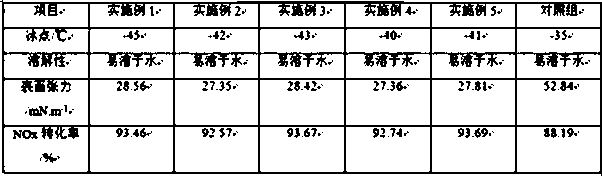

Examples

Embodiment 1

[0025] The preparation of amido carboxylate type gemini surfactant: get N,N-dimethylpropylenediamine, ethylenediaminetetraacetic dianhydride, triethylamine according to the molar mass ratio of 1.0:2.5:0.2, and N , N-dimethylpropylenediamine and triethylamine were dissolved in tetrahydrofuran and placed in a three-necked flask, and ethylenediaminetetraacetic dianhydride was divided into three parts on average, and then added to the three-necked flask in batches. React for 18.5 hours. After the reaction, place the reaction solution in a rotary evaporator to evaporate tetrahydrofuran, then wash it with water 4 times to remove unreacted ethylenediaminetetraacetic acid dianhydride, cool and filter under reduced pressure to separate the crude product, and then use ethanol, methanol The mixed solvent is recrystallized to obtain the amido carboxylate type gemini surfactant.

[0026] Preparation of urea solution: Mix 38 parts of urea with 70 parts of high-purity water with a resistivit...

Embodiment 2

[0029] The preparation of amido carboxylate type gemini surfactant: take N,N-dimethylpropylenediamine, ethylenediaminetetraacetic dianhydride, triethylamine according to the molar mass ratio of 1.0:2.6:0.2, and N , N-dimethylpropanediamine and triethylamine were dissolved in tetrahydrofuran and placed in a three-necked bottle, and ethylenediaminetetraacetic dianhydride was divided into three parts on average, and then added to the three-necked bottle in batches. React for 19 hours. After the reaction, place the reaction solution in a rotary evaporator to evaporate THF to remove THF, then wash with water 3.5 times to remove unreacted ethylenediaminetetraacetic dianhydride, cool and filter under reduced pressure to separate the crude product, and then mix it with ethanol and methanol Solvent recrystallization promptly obtains amido carboxylate type gemini surfactant.

[0030] Preparation of urea solution: Mix 32 parts of urea with 80 parts of high-purity water with a resistivity...

Embodiment 3

[0033] The preparation of amido carboxylate type gemini surfactant: get N,N-dimethylpropylenediamine, ethylenediaminetetraacetic dianhydride, triethylamine according to the molar mass ratio of 1.0:2.8:0.2, and N , N-dimethylpropanediamine and triethylamine were dissolved in tetrahydrofuran and placed in a three-necked bottle, and ethylenediaminetetraacetic dianhydride was divided into three parts on average, and then added to the three-necked bottle in batches. React for 18 hours. After the reaction, place the reaction solution in a rotary evaporator to evaporate THF to remove THF, then wash with water 4.5 times to remove unreacted EDTA, cool and filter under reduced pressure to separate the crude product, then mix with ethanol and methanol Solvent recrystallization promptly obtains amido carboxylate type gemini surfactant.

[0034] Preparation of urea solution: Mix 30 parts of urea with 75 parts of high-purity water with a resistivity of 18.5MΩ·cm evenly, stir and mix for 9 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com