A Production Process for Improving Double Caramel Flavor

A production process and caramel color technology, which is applied in the field of production technology for improving double caramel color flavor, can solve problems such as poor flavor of double caramel color, and achieve the effects of improving flavor, good flavor and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

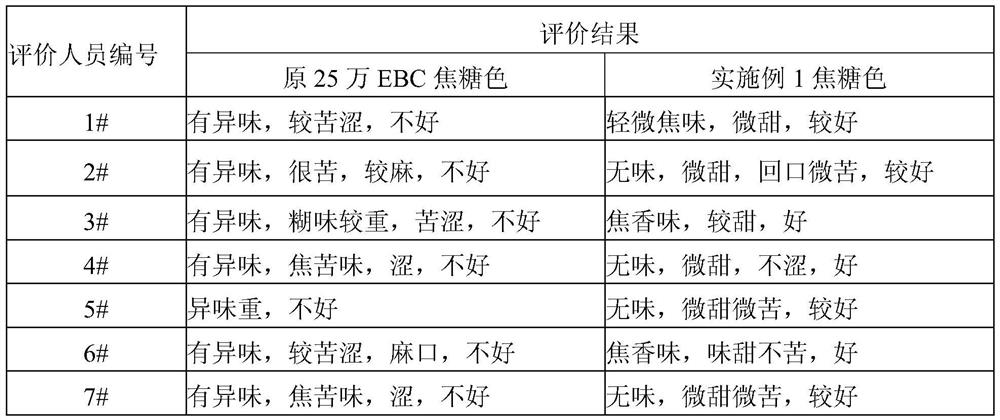

Embodiment 1

[0039] A production process for improving double caramel flavor, comprising the following steps:

[0040] 1), metering and concentration of raw materials: measure the glucose syrup with a dry matter of 6000kg and a DE value of 97% into the reaction tank, and concentrate to a dry basis of 60%;

[0041]2), primary catalyst: Add 800kg of sodium sulfite, 400kg of ammonium sulfite, 12kg of ferric chloride, and 30kg of acetic acid into the concentrated glucose syrup, start stirring and mix thoroughly;

[0042] 3), the first pressurized reaction: pressurize and heat up the above-mentioned syrup with the catalyst in the reaction tank, and control the pressure of the pressure gauge in the tank to 0.4Mpa during the reaction process, and the temperature in the tank to 150°C. Sampling and testing every 30 minutes Its color rate, when the color rate is 0.190 (converted into EBC unit is 0.190÷0.076×20000=50000EBC, the same below), stop a reaction;

[0043] 4), secondary catalyst: add 600 g...

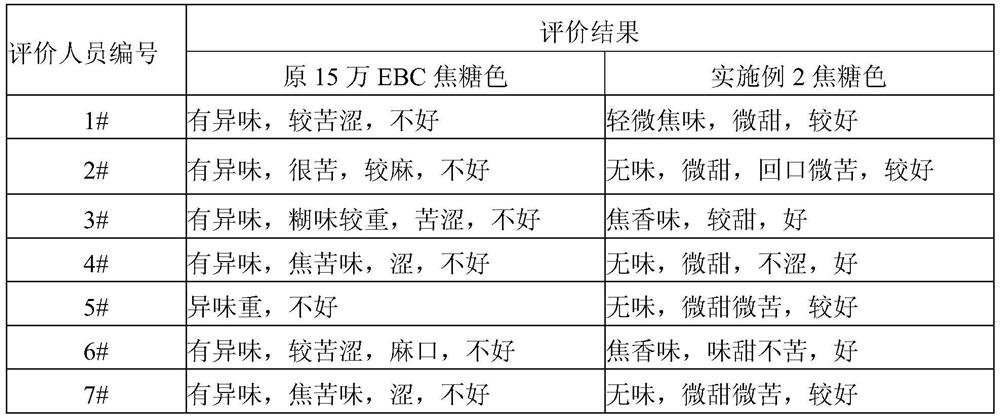

Embodiment 2

[0052] Production 30Be, 150000EBC double caramel color

[0053] A production process for improving double caramel flavor, comprising the following steps:

[0054] 1), metering and concentration of raw materials: measure the glucose syrup with a dry matter of 6000kg and a DE value of 98% into the reaction tank, and concentrate it to a dry basis of 70%;

[0055] 2), primary catalyst: Add 400kg of sodium sulfite, 200kg of ammonium sulfite, 12kg of aluminum trichloride, and 30kg of benzoic acid to the concentrated glucose syrup, start stirring and mix thoroughly;

[0056] 3), the first pressurized reaction: pressurize and heat up the above-mentioned syrup with the catalyst in the reaction tank, and control the pressure of the pressure gauge in the tank to 0.4Mpa during the reaction process, and the temperature in the tank to 150°C. Sampling and testing every 30 minutes Its color rate, when the color rate is about 0.100, a reaction is terminated;

[0057] 4), secondary catalyst: ...

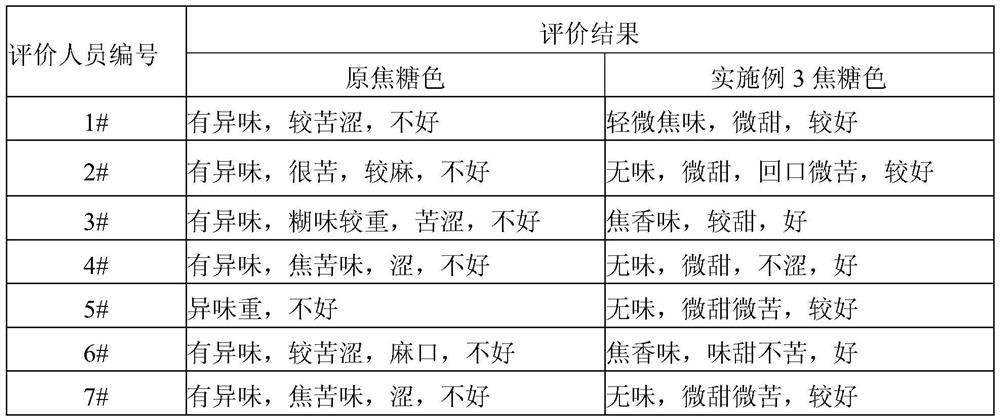

Embodiment 3

[0066] Production 30Be, 75000EBC double caramel color

[0067] A production process for improving double caramel flavor, comprising the following steps:

[0068] 1), metering and concentration of raw materials: measure the glucose syrup with a dry matter of 6000kg and a DE value of 94% into the reaction tank, and concentrate it to a dry basis of 80%;

[0069] 2), primary catalyst: Add 200kg of sodium sulfite, 100kg of ammonium sulfite, 12kg of boron trifluoride, and 30kg of dodecanoic acid to the concentrated glucose syrup, start stirring and mix thoroughly;

[0070] 3), the first pressurized reaction: pressurize and heat up the above-mentioned syrup with the catalyst in the reaction tank, and control the pressure of the pressure gauge in the tank to 0.4Mpa during the reaction process, and the temperature in the tank to 150°C. Sampling and testing every 30 minutes Its color rate, when the color rate is about 0.60, a reaction is terminated;

[0071] 4), secondary catalyst: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com