Internal drive-external power generation integrated pulse generator power supply

A generator and internal drive technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the axial length of the system, torque impact of couplings, poor structural compactness, etc., and achieve simplified axial length, Effects of improving compactness, increasing energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

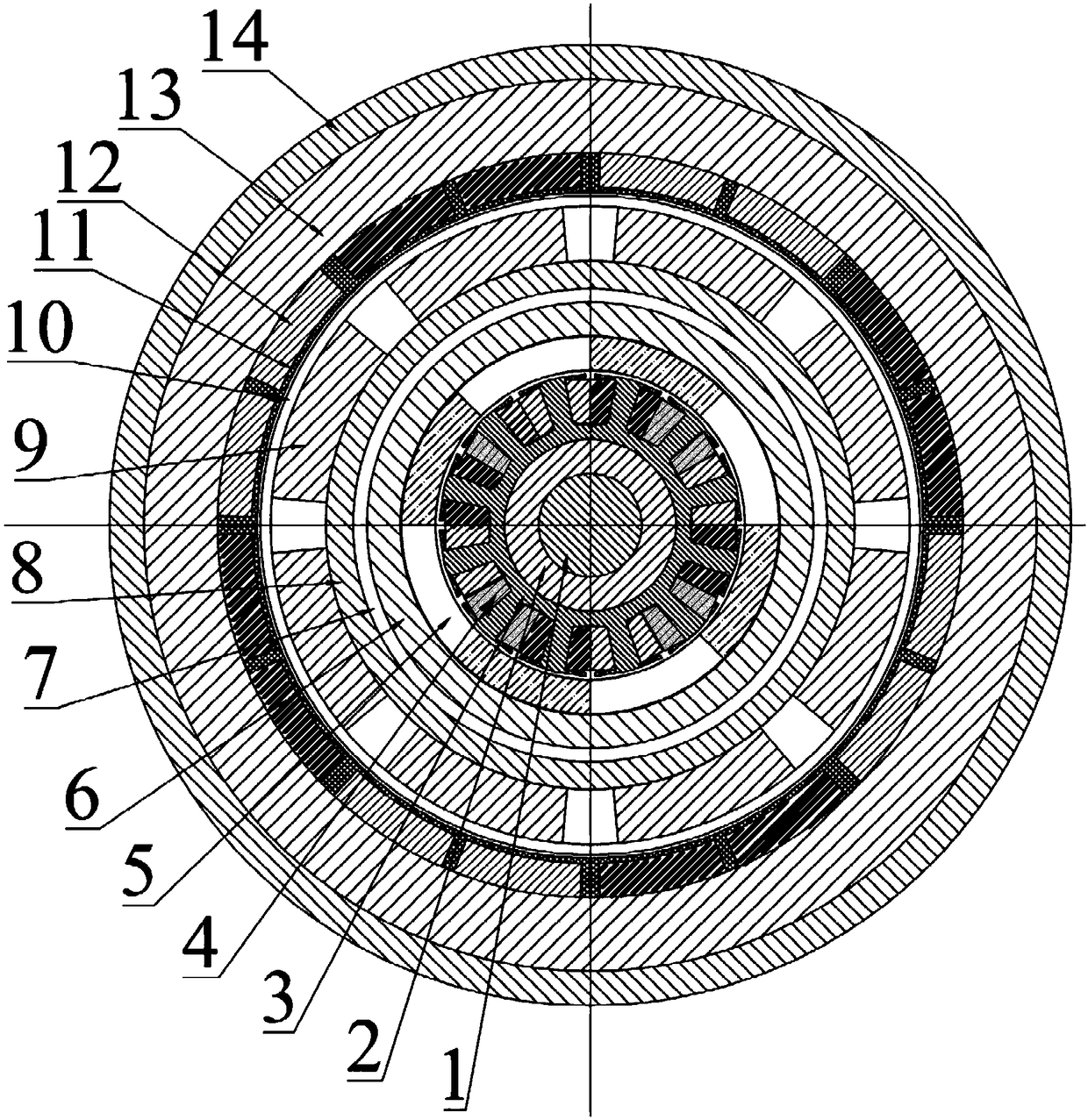

[0017] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail, the internal drive-external power generation integrated pulse generator power supply described in this embodiment includes a casing 14, a magnetic isolation ring 7, a motor and a generator,

[0018] A generator is arranged inside the casing 14, and a motor is arranged inside the generator, and the electromagnetic field is separated by a magnetic isolation ring 7 between the generator and the motor;

[0019] The motor includes a rotating shaft 1, a motor stator yoke 2, a motor stator core 3 and a motor rotor core 6,

[0020] The motor stator yoke 2 is fixed on the outer peripheral surface of the rotating shaft 1. The motor stator core 3 is arranged on the outer peripheral surface of the motor stator yoke 2. The outer surface of the motor stator core 3 is uniformly distributed with rotor teeth along the circumferential direction. The rotor teeth are wound with The motor armature windi...

Embodiment 1

[0026] The internal drive-external power generation integrated pulse generator power supply is characterized in that it includes a casing 14, a magnetic isolation ring 7, a motor and a generator,

[0027] A generator is arranged inside the casing 14, and a motor is arranged inside the generator, and the electromagnetic field is separated by a magnetic isolation ring 7 between the generator and the motor;

[0028] The motor includes a rotating shaft 1, a motor stator yoke 2, a motor stator core 3 and a motor rotor core 6,

[0029] The motor stator yoke 2 is fixed on the outer peripheral surface of the rotating shaft 1. The motor stator core 3 is arranged on the outer peripheral surface of the motor stator yoke 2. The outer surface of the motor stator core 3 is uniformly distributed with rotor teeth along the circumferential direction. The rotor teeth are wound with An eight-pole three-phase motor armature winding 4, a motor rotor iron core 6 is arranged on the inner circular su...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment is a further description of the internal drive-external power generation integrated pulse generator power supply described in Embodiment 1. In this embodiment, the generator rotor yoke 8 is a non-magnetic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com