Stacked chip packaging structure based on special-shaped resin gasket

A chip packaging structure and resin technology, applied in electrical components, electric solid state devices, circuits, etc., can solve the problems of fragile silicon-based wafer gaskets, consumption of auxiliary materials, and high production costs, achieving unlimited thickness and flexibility. Good, easy-to-save effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

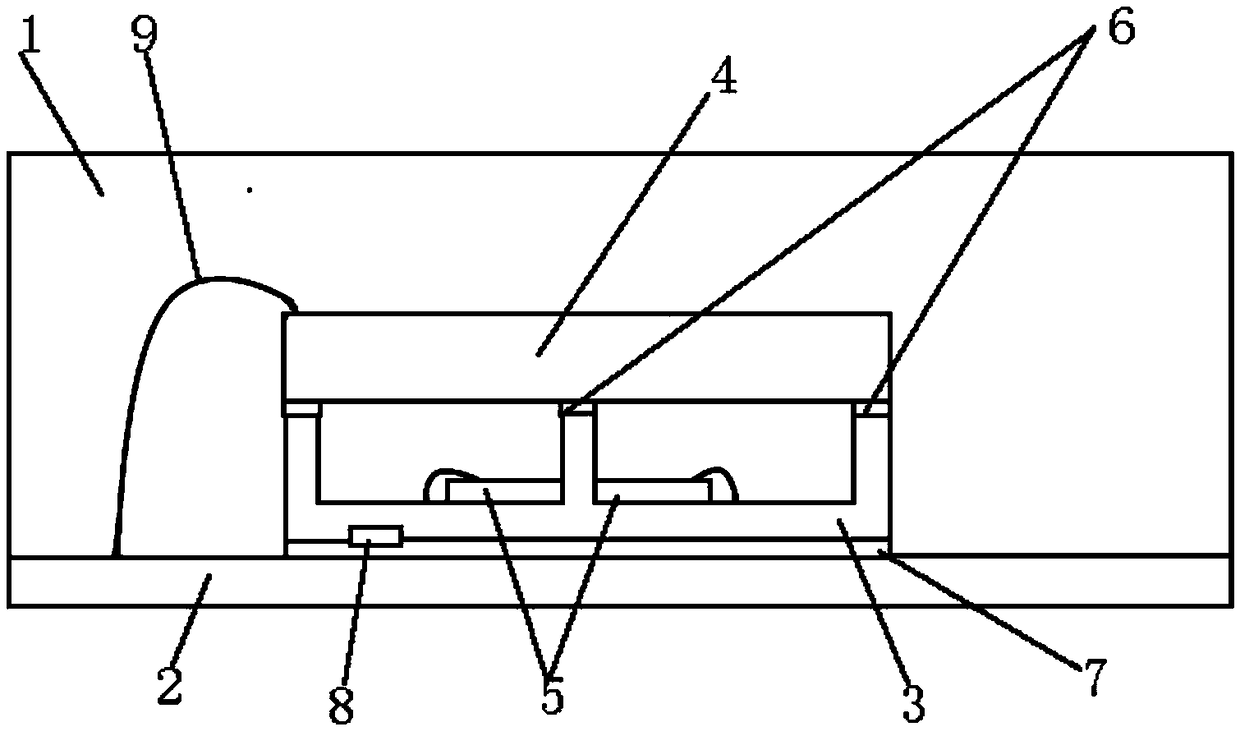

[0039] This embodiment provides a stacked chip packaging structure based on a special-shaped resin pad, as shown in Figure 1, including a circuit board 2, a first adhesive layer 7, a special-shaped resin pad 3, and a second adhesive layer stacked in sequence. 6, the first chip 4, packaging material 1 is packaged on the circuit board 2 with the first adhesive layer 7, the special-shaped resin gasket 3, the second adhesive layer 6, and the first chip 4, and the first chip 4 is soldered The line 9 is electrically connected to the circuit board 2;

[0040] The special-shaped resin spacer 3 has two cavities divided by a partition, the cavities are open at the top, and a second chip 5 is arranged in each cavity, and the second chip 5 is bonded with a wire by welding. The circuit board 2 is electrically connected.

[0041] Preferably, the shaped resin gasket 3 is based on fiberglass cloth, and the weight ratio of the fiberglass cloth is 10-60wt%, and the following components are att...

Embodiment 2

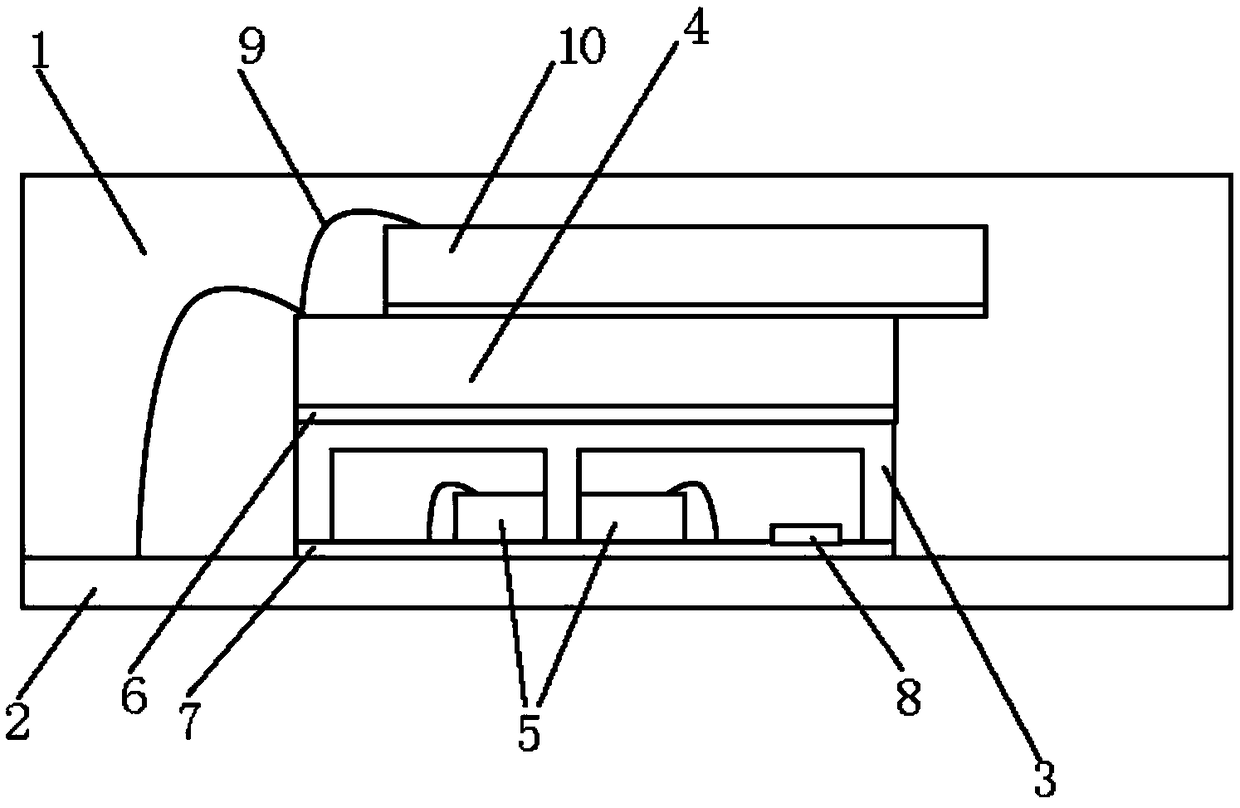

[0061] This embodiment provides a stacked chip packaging structure based on special-shaped resin pads, as shown in Figure 2, including a circuit board 2, a first adhesive layer 7, a special-shaped resin pad 3, and a second adhesive layer stacked in sequence. 6, the first chip 4, packaging material 1 is packaged on the circuit board 2 with the first adhesive layer 7, the special-shaped resin gasket 3, the second adhesive layer 6, and the first chip 4, and the first chip 4 is soldered The line 9 is electrically connected to the circuit board 2;

[0062] The special-shaped resin spacer 3 has two cavities divided by a partition, the cavities are opened at the bottom, and a second chip 5 is arranged in each cavity, and the second chip 5 is connected to the The circuit board 2 is electrically connected.

[0063] The special-shaped resin gasket 3 is based on fiberglass cloth, and the weight ratio of the fiberglass cloth is 10-60wt%, and the following components are attached to it, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com