A method for digitally design the tooth profile of a rack and pinion pair of a mechanical ratio variable steering gear

A design method, rack and tooth technology, applied in mechanical equipment, electrical digital data processing, design optimization/simulation, etc., can solve the problems of calculation step limitation, large design error, low design accuracy, etc., and achieve no principle error , to achieve the effect of digital solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

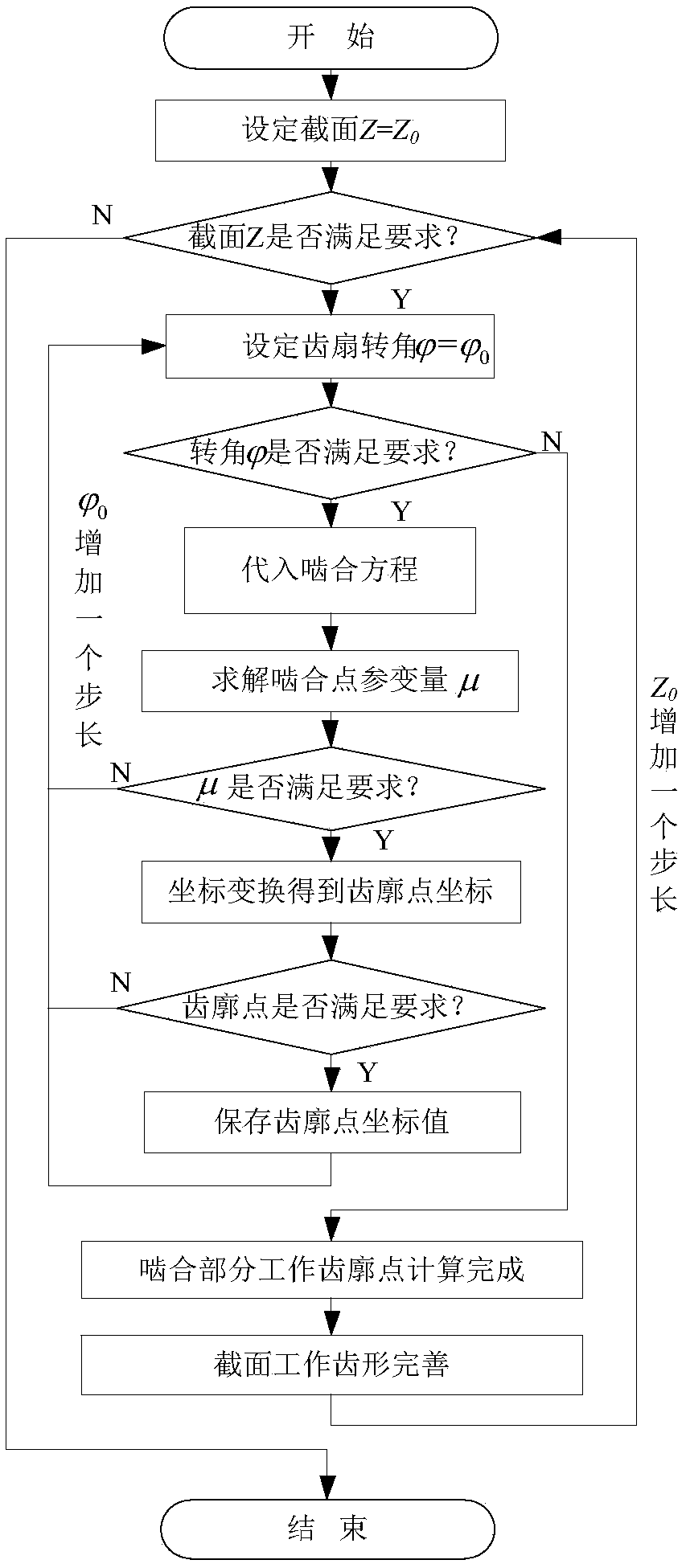

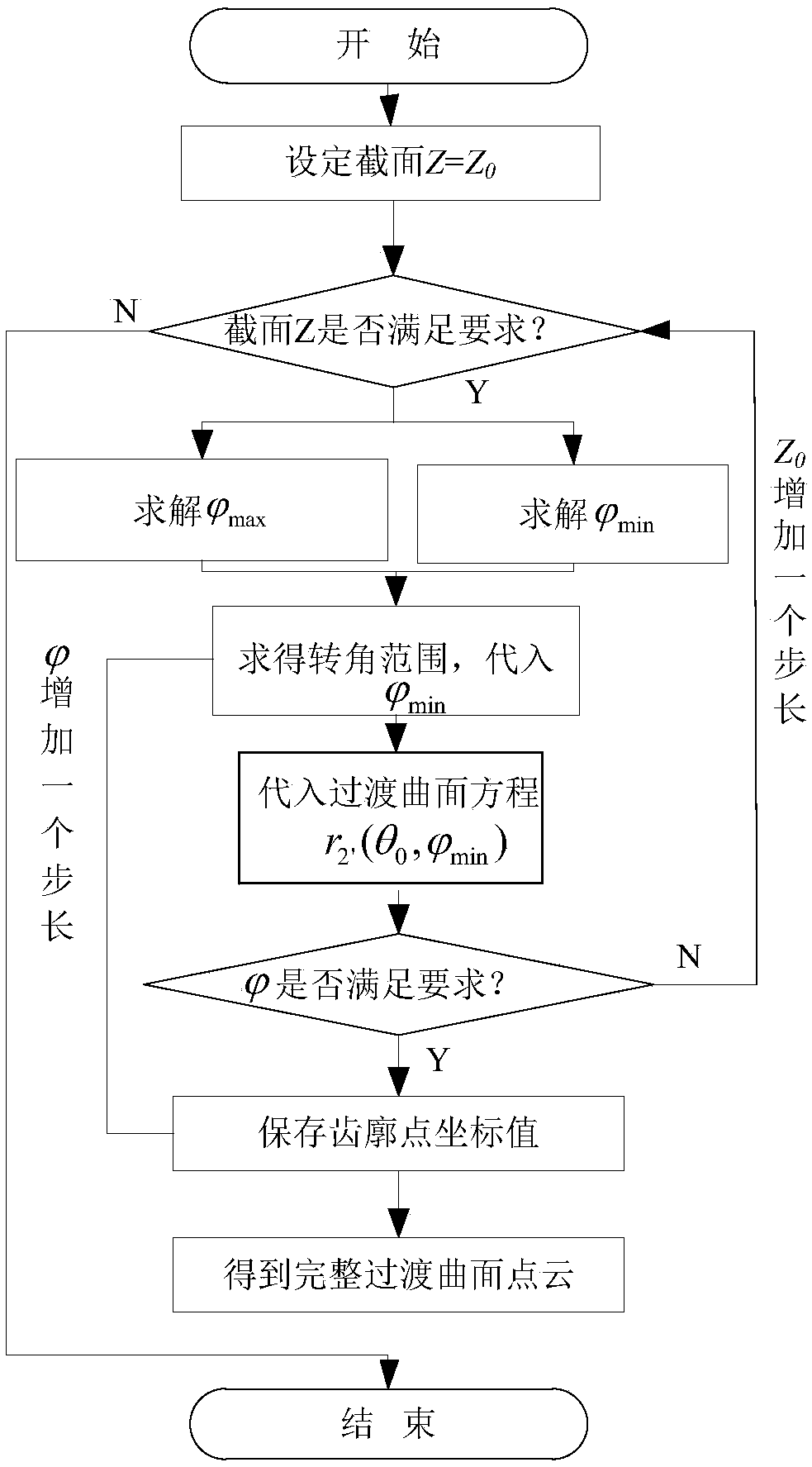

[0029] Such as figure 1 , figure 2 As shown, the present invention includes the following steps: S1: calculation step of basic design parameters; S2: step of determining section; S3: step of selecting gear angle; S4: calculating meshing equation; ; S6: the step of finding the point cloud of the transformation ratio rack transition surface; S7: the step of perfecting the tooth shape; S8: the step of solving the tooth profile of the selected section rack; S9: the step of solving the tooth profile of the entire rack.

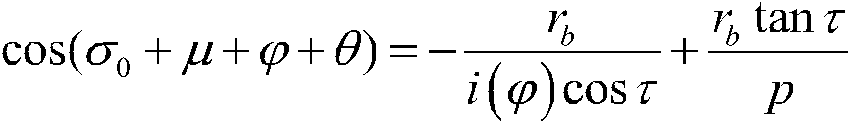

[0030] The meshing equation is:

[0031]

[0032] where r b is the radius of the base circle, σ 0 It is related to the parameters of the involute gear, and its magnitude is σ 0 = π / 2z-invα 1′ , z is the number of gear teeth; invα 1′ is the involute polar coordinate function, inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com