Two-dimensional optical transfer function measuring device and method

A technology of optical transfer function and measuring device, which is applied in the direction of testing optical properties, etc., can solve problems such as expensive, only one-dimensional results, and diffusion function deviation, and achieve the effects of convenient operation, fast measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

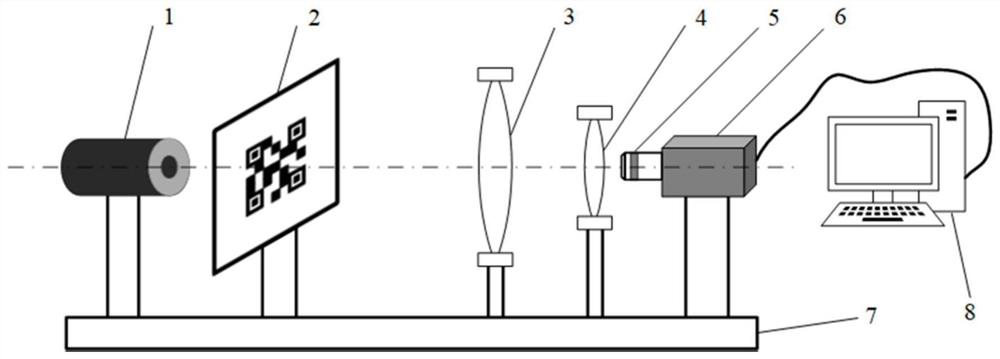

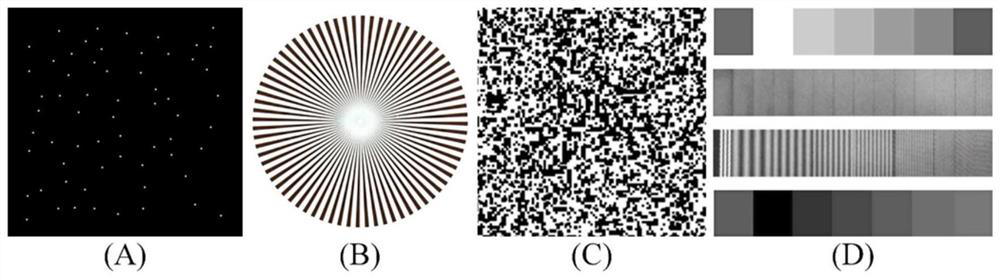

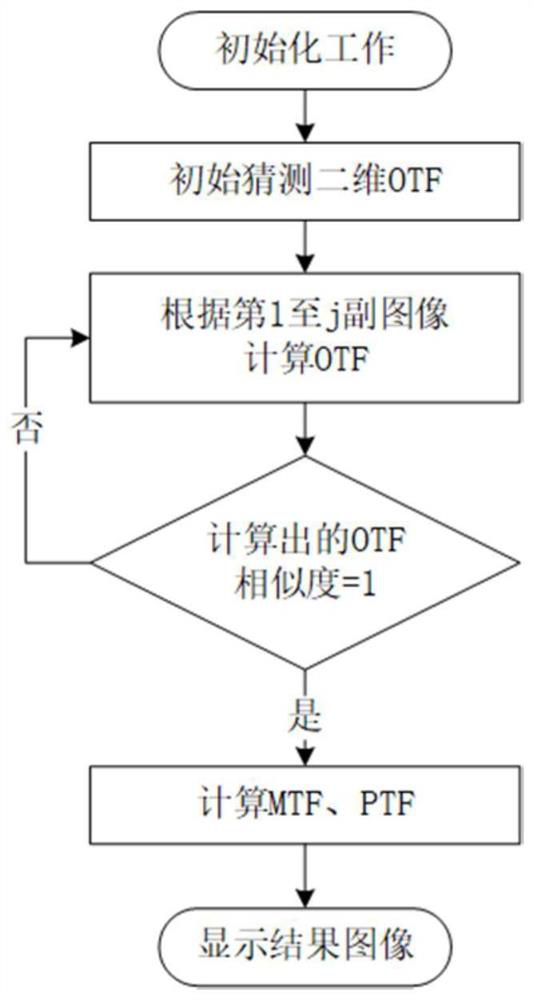

[0034] For common photography, monitoring, and industrial imaging lenses, that is, the infinite-finite conjugate lens to be tested, the light source 1, the random coding plate 2, the collimator 3, the lens to be tested 4, the microscope 5, and the two-dimensional photoelectric detection The detectors 6 are all fixed on the base 7, and adjusted to align the optical axes, and focus until the image is clear. Select the light source 1 with the same wavelength according to the measurement requirements, and the light source 1 is uniformly irradiated on the random coding plate 2, and the random coding plate 2 is located at the front focal plane of the collimating mirror 3 , imaged at infinity by the collimating mirror 3, according to the F-number and the measurement requirement wavelength of the lens to be tested 4, determine its cut-off frequency, the cut-off frequency is 1 / (wavelength*F number), thus select The random coding plate 2 whose spatial frequency (reciprocal of size) is h...

Embodiment 2

[0048] For the lens 4 to be tested whose working distance is finite, that is, the finite-finite conjugate, the collimating mirror 3 is not needed, and the random coding plate 2 is directly placed on the lens to be tested. The measurement of the lens 4 requires the position. The following measurement steps are consistent with Example 1.

Embodiment 3

[0050] For the infinity-infinity conjugated lens 4 to be measured, such as a telescope, a relay lens is added after the lens to be measured 4, the overall equivalent of the lens 4 to be measured in Embodiment 1, and other The measurement procedure is consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com