Tunnel supporting pipe

A technology for pipe fittings and tunnels, applied in the field of support components for tunnel excavation, which can solve the problems of small concrete flow space and insufficient bonding strength, and achieve the effect of firm concrete structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

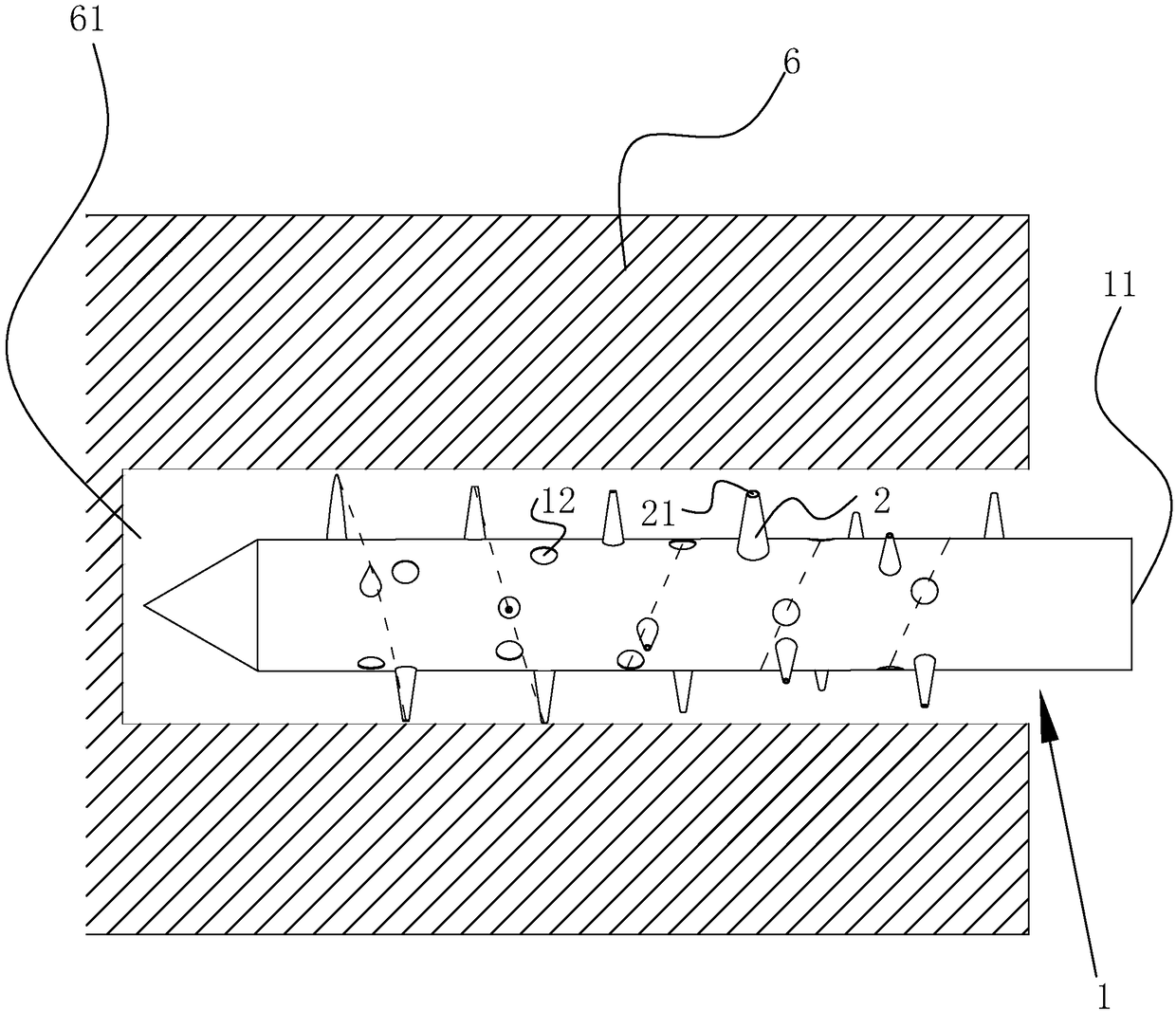

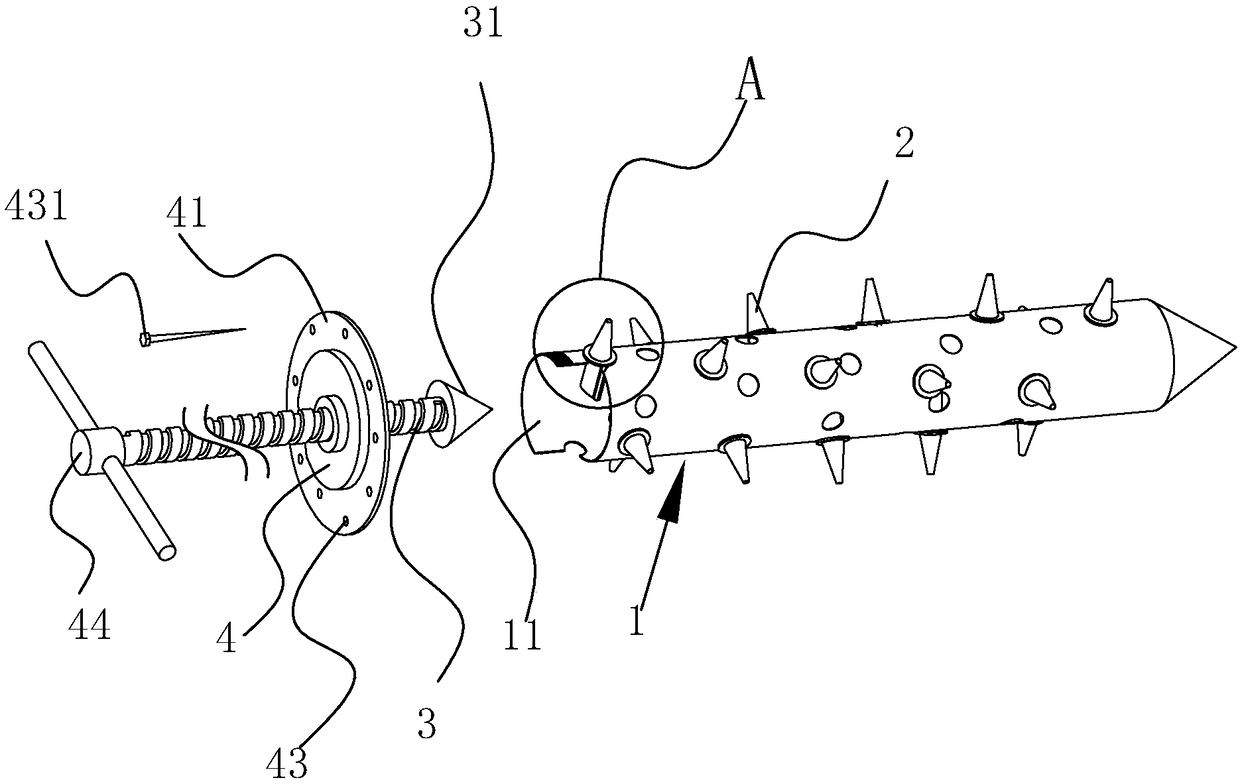

[0042] Example 1, pipe fittings used for tunnel support, such as figure 1 As shown, the tube body 1 is included. The body of the tube body 1 is a cylinder with a hollow inside; one end of the tube body 1 is conical, and the other end of the tube body 1 is provided with a grouting port 11.

[0043] A conical strut 2 is fixed on the outer wall of the pipe body 1, and the strut 2 is hollowed out to form a grouting hole 21; one end of the grouting hole 21 is connected to the hollow part of the pipe body 1, and the grouting hole 21 The other end of the grouting rod is placed at the outer end of the support rod 2; the minimum hole diameter of the grouting hole 21 is 2cm. When the slurry is poured into the grouting port 11 of this size, the mud will flow along the grouting hole 21 to The outer wall of the tube body 1. The support rod 2 is arranged along the spiral track of the length of the pipe body 1, figure 1 In the middle, the two dashed lines on the left refer to the spiral traject...

Embodiment 2

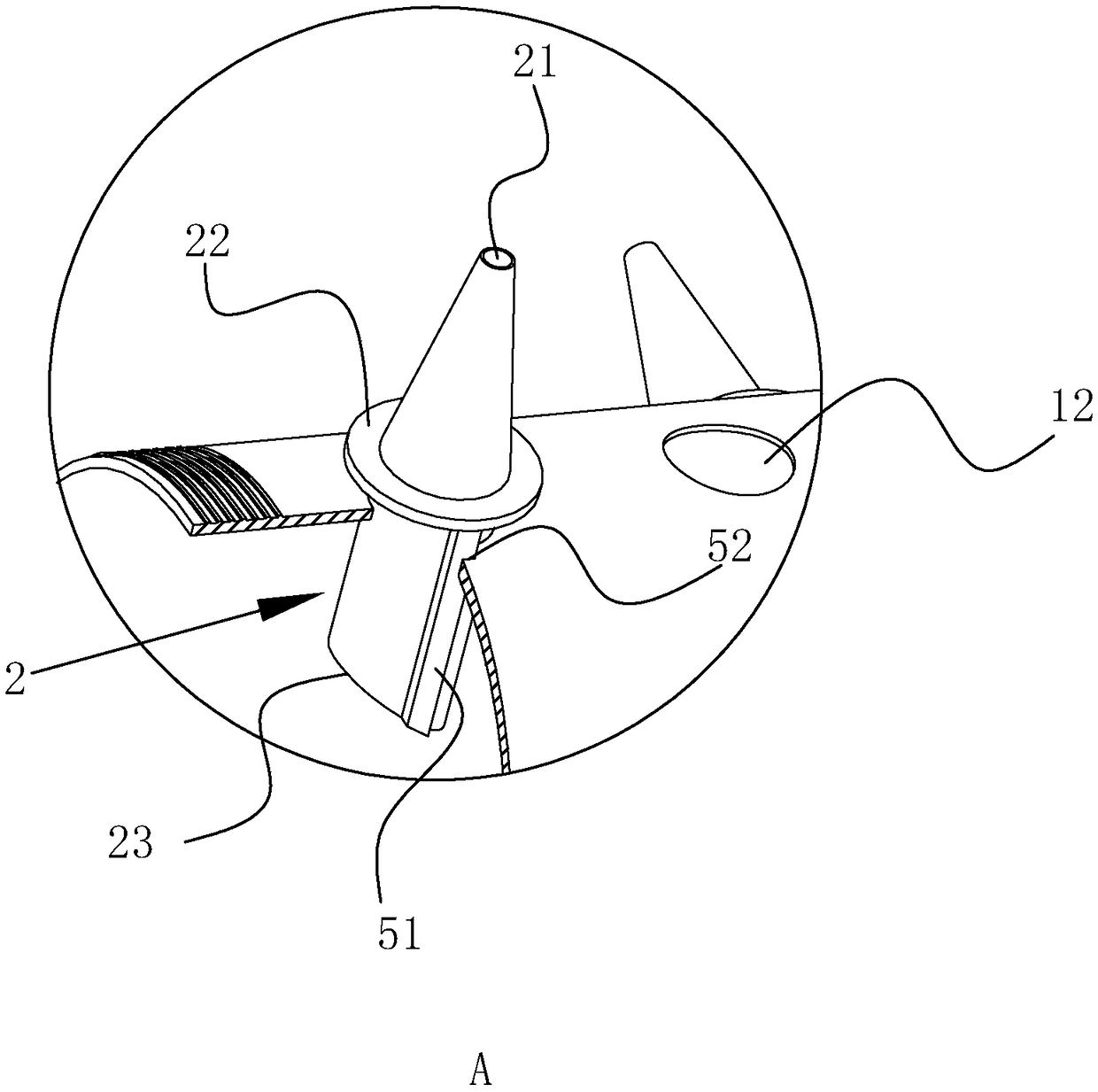

[0046] Embodiment 2, a pipe used for tunnel support, which is different from Embodiment 1 in that: figure 2 versus image 3 As shown, the outer wall of the tube body 1 is provided with an opening, and the support rod 2 can slide outward along the opening diameter of the tube body 1. The friction force between the support rod 2 and the wall of the opening is used to make the support rod 2 in It can be positioned on the opening without external force.

[0047] The support rod 2 is divided into two parts, one part is the cone part outside the tube body 1, and the other part is the cylindrical part inside the tube body 1. The bottom of the cone part is fixed with an annular stop 22, which is opposite to the tube The outer wall of the body 1 is blocked, making it difficult for the conical part of the strut 2 to retract into the tube body 1 as a whole.

[0048] The lower bottom surface of the cylindrical part of the support rod 2 is an elliptical inclined surface 23, and the inclined su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com