UV semi-curing OCA (optical clear adhesive) and use thereof

A semi-curing and ultraviolet light technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of soft-to-soft bonding between touch modules and display modules, and OCA Glue overflow problem, low initial viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare adhesive composition according to following formula:

[0049] 47.0 parts Dymax Corporation BR3641AJ;

[0050] 20.0 parts of Sartomer SR506, isobornyl acrylate;

[0051] 27.35 parts of 2-EHA, isooctyl acrylate from Osaka Organic Chemicals;

[0052] 3.2 parts Osaka Organic 2-HEA, Hydroxyethyl Acrylate

[0053] 0.35 parts BASF Irganox 1726 as antioxidant

[0054] 0.1 part BYK 088

[0055] 0.4 parts Omnirad TPO, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0056] 1.6 parts Omnirad 651: Benzoin Dimethyl Ether

[0057] All parts are parts by weight, based on 100 parts by weight of the adhesive composition;

[0058] Specific preparation method:

[0059] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at 2500 rpm, disperse and mix at high speed for 10 minutes.

Embodiment 2

[0061] 50.0 copies of Rahn AG UA 12-109;

[0062] 17.0 parts of Sartomer SR506, isobornyl acrylate;

[0063] 27.35 parts of 2-EHA, isooctyl acrylate from Osaka Organic Chemicals;

[0064] 3.2 parts Osaka Organic 2-HEA, Hydroxyethyl Acrylate

[0065] 0.35 parts BASF Irganox 1726 as antioxidant

[0066] 0.1 part BYK 088

[0067] 0.4 parts Omnirad TPO, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0068] 1.6 parts Omnirad MBF, methyl benzoylformate

[0069] All parts are parts by weight, based on 100 parts by weight of the adhesive composition;

[0070] Specific preparation method:

[0071] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at 2500 rpm, disperse and mix at high speed for 10 minutes.

Embodiment 3

[0073] Prepare adhesive composition according to following formula:

[0074] 69.6 copies of Etercure 61360 from Changxing Chemical Company;

[0075] 12.1 parts of Sartomer SR506, isobornyl acrylate;

[0076] 12.1 parts of Sartomer 395 NS from Sartomer Company, isodecyl acrylate;

[0077] 3.55 parts Osaka Organic 4-HBA, 4-Hydroxybutyl Acrylate

[0078] 0.35 parts BASF Irganox 1726 as antioxidant

[0079] 0.1 part BYK 088

[0080] 0.4 parts Omnirad TPO, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0081] 1.8 parts Omnirad MBF, methyl benzoylformate

[0082] All parts are parts by weight, based on 100 parts by weight of the adhesive composition;

[0083] Specific preparation method:

[0084] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at 2500 rpm, disperse and mix at high speed for 10 minutes.

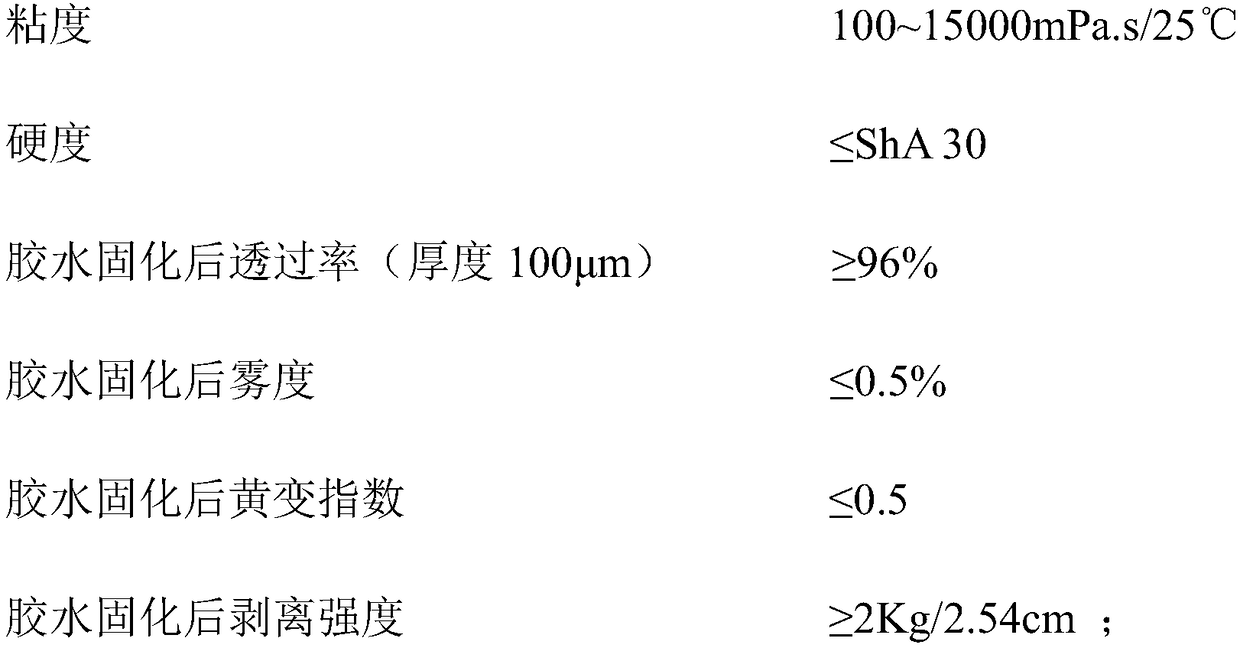

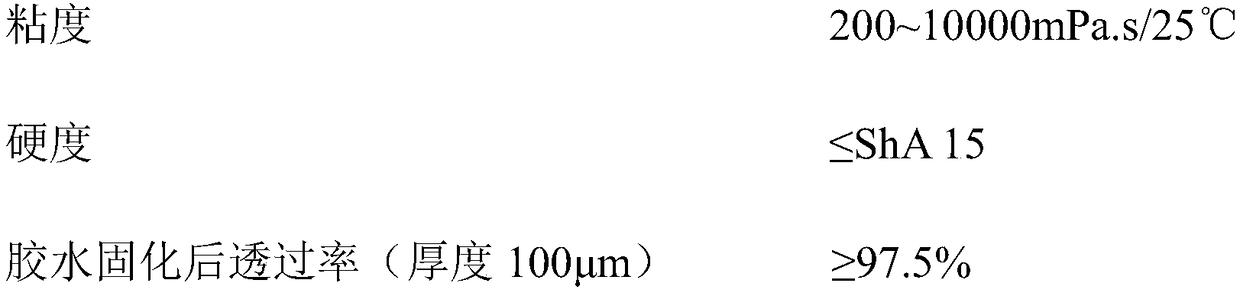

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com