rGO/CL-20 self-supporting fibrous solid propellant as well as preparation method and application thereof

A CL-20, solid propellant technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, detonating cord, etc., can solve the problem of poor self-sustaining combustion performance, low thermal conductivity, difficult solid propellants, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

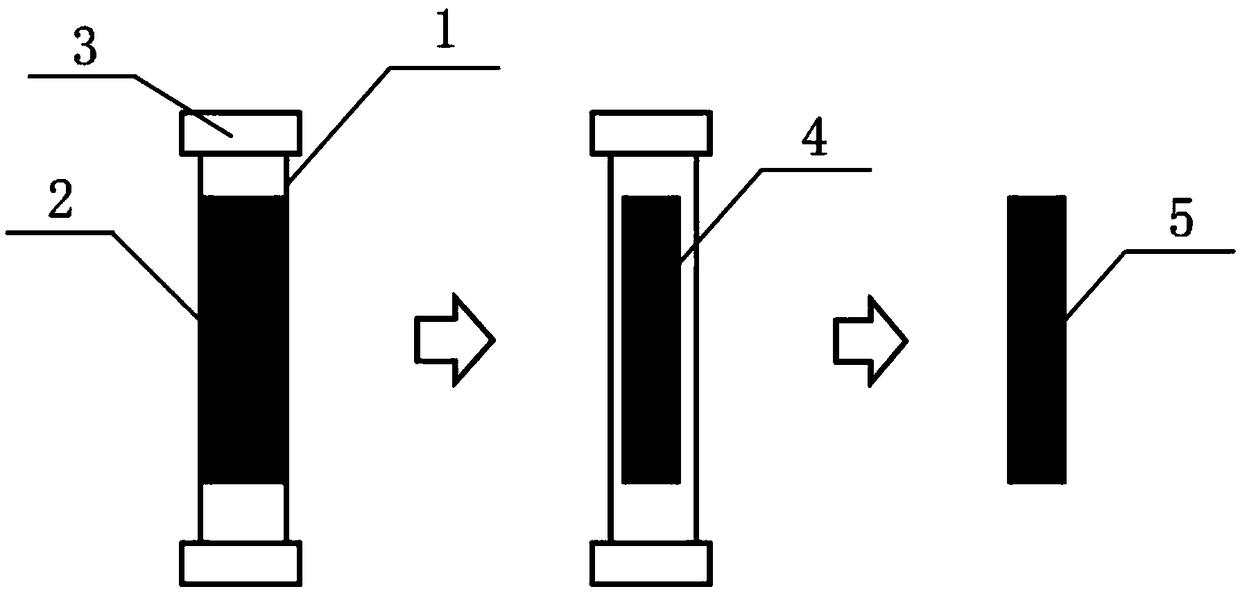

[0039] as attached figure 1As shown, 0.2g CL-20 fine powder was added into 1mL deionized water, stirred for 10min and then ultrasonically dispersed for 10min. Add 1 g of GO hydrogel to the above dispersion, stir for 1 hour with magnetic force, and then add VC equal in mass to GO to obtain GO / CL-20 / VC aqueous solution 2. The GO / CL-20 / VC aqueous solution 2 was poured into the capillary glass tube 1, sealed with a sealing cap 3, and then placed in an oven for hydrothermal reaction for 1 hour at a reaction temperature of 90°C. After the sample was naturally cooled, the sample was taken out from the glass capillary, immersed in deionized water and rinsed three times to obtain rGO / CL-20 hydrogel 4, and then dried naturally to obtain rGO / CL-20 self-supporting fibrous solid propellant 5. Finally, three parts of rGO / CL-20 self-supporting fibrous solid propellant 5 were respectively immersed in 0.05M, 0.1M and 0.2M KOH aqueous solution for 1h, and then dried in an oven at 60°C for 2h ...

Embodiment 2

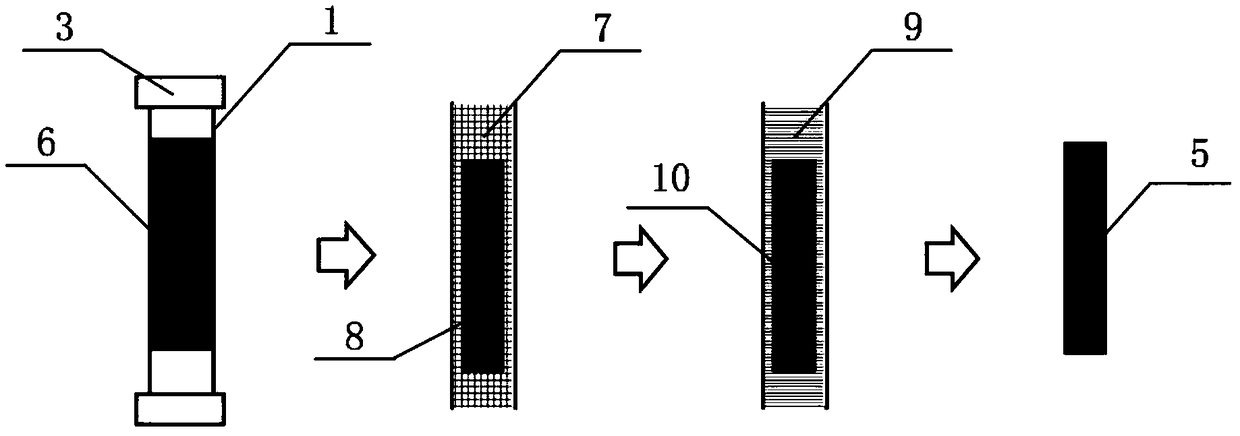

[0041] as attached figure 2 As shown, 1 g of GO aqueous sol was magnetically stirred for 1 h and then VC with the same mass as GO was added to obtain GO / VC aqueous solution 6. The GO / VC aqueous solution 6 was poured into the capillary glass tube 1, sealed with a sealing cap 3, and then placed in an oven for hydrothermal reaction for 1 hour at a reaction temperature of 90°C. After the sample was cooled naturally, the sample was taken out from the glass capillary, immersed in deionized water for 3 washes, and then transferred to acetone 7. After solvent replacement, the rGO fiber 8 after acetone was replaced with water was obtained, and transferred to 100mol / L CL-20 In solution 9, after the CL-20 molecules fully diffused into the rGO fibers, the rGO fibers 10 replaced by CL-20 in acetone solution were obtained, and then naturally dried and shaped to obtain the rGO / CL-20 self-supporting fibrous solid propellant 5 . Finally, the rGO / CL-20 self-supporting fibrous solid propellant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com