Optical glass and preparation method thereof

A technology of optical glass and press molding, which is applied in glass manufacturing equipment, glass pressing, glass molding, etc. It can solve problems such as poor devitrification resistance, increased glass density, and aggravated corrosion of melting vessels, so as to improve chromatic aberration , excellent performance, light weight and miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] The present invention also provides a method for preparing the optical glass according to the present invention, which includes: weighing and mixing the components according to the proportion, mixing them uniformly, melting them, and then pouring or leaking them into a molding mold, or directly pressing them into shape.

[0114] Specifically, the preparation method includes: weighing each component according to a specified ratio, mixing them uniformly to make batches, and putting the prepared batches into a smelting device made of quartz or corundum, etc., at 800 It is melted in an oxidizing atmosphere at a temperature of -1350°C, stirred evenly, and then poured into water. Drain and dry the poured cullet and put it into a crucible made of precious metals (Au, Pt, etc.) for secondary melting, and pour or leak into a molding mold for molding, or directly press molding.

[0115] The present invention also provides an optical element comprising the optical glass of the pre...

Embodiment

[0117] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only for illustrating the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products.

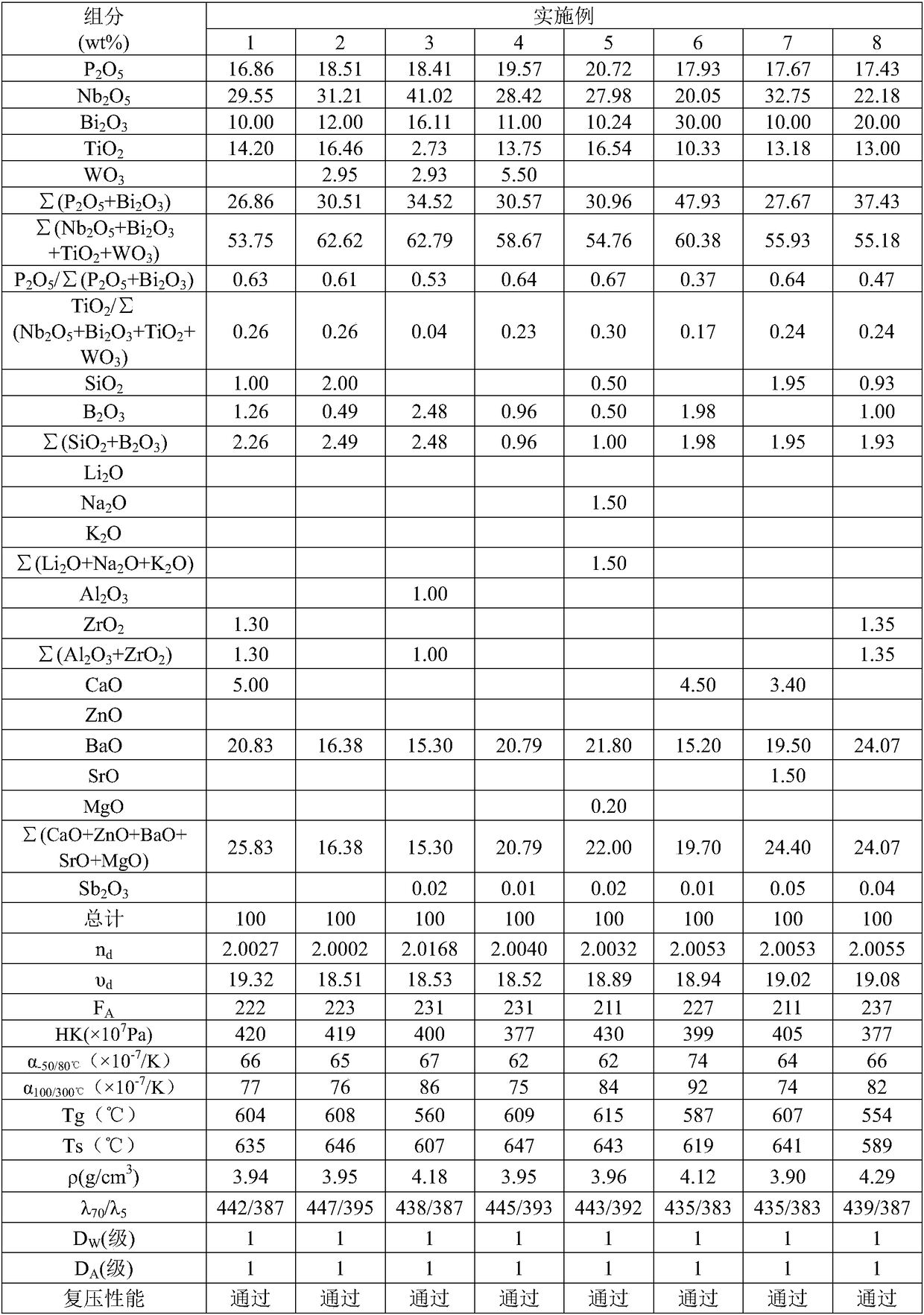

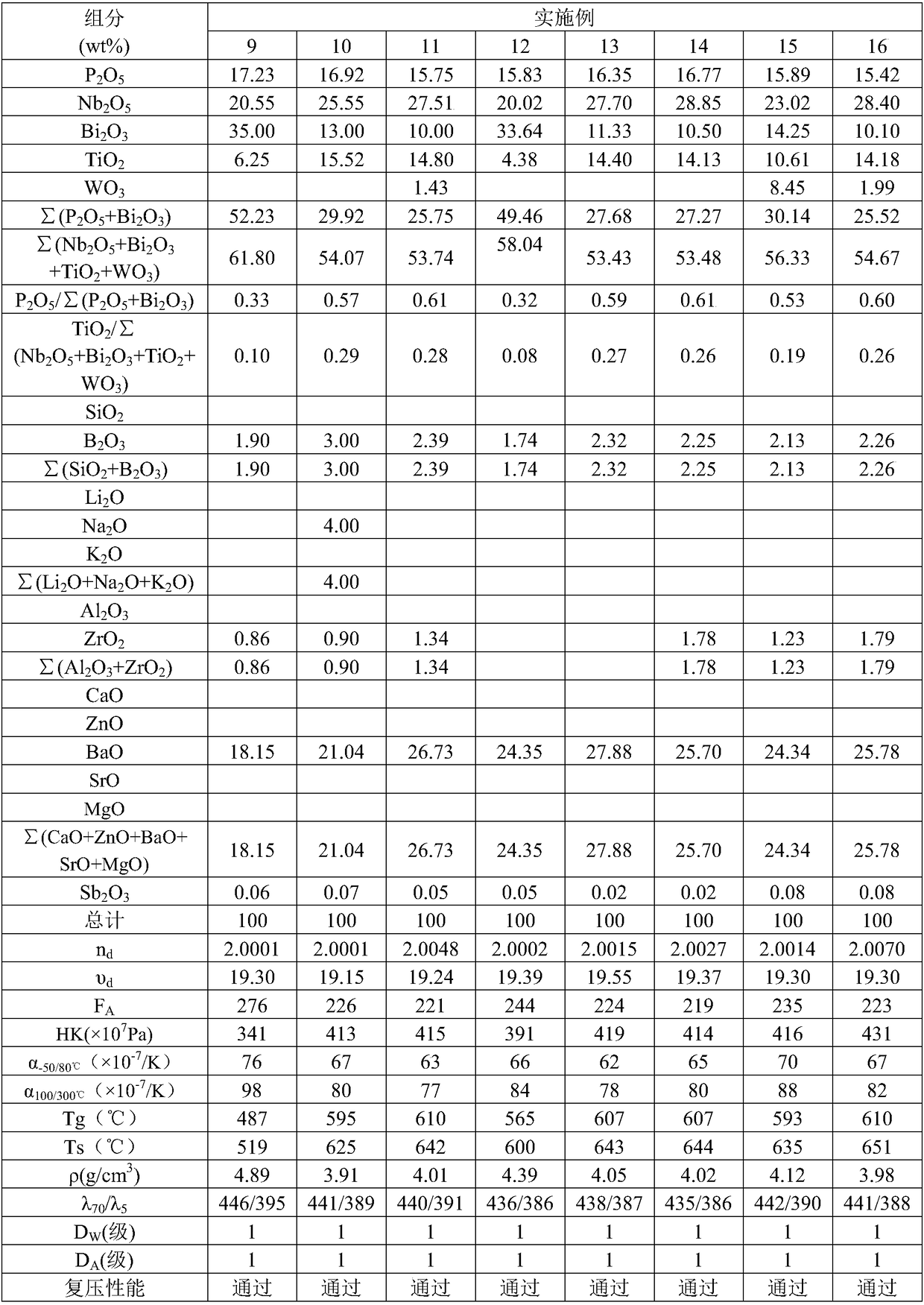

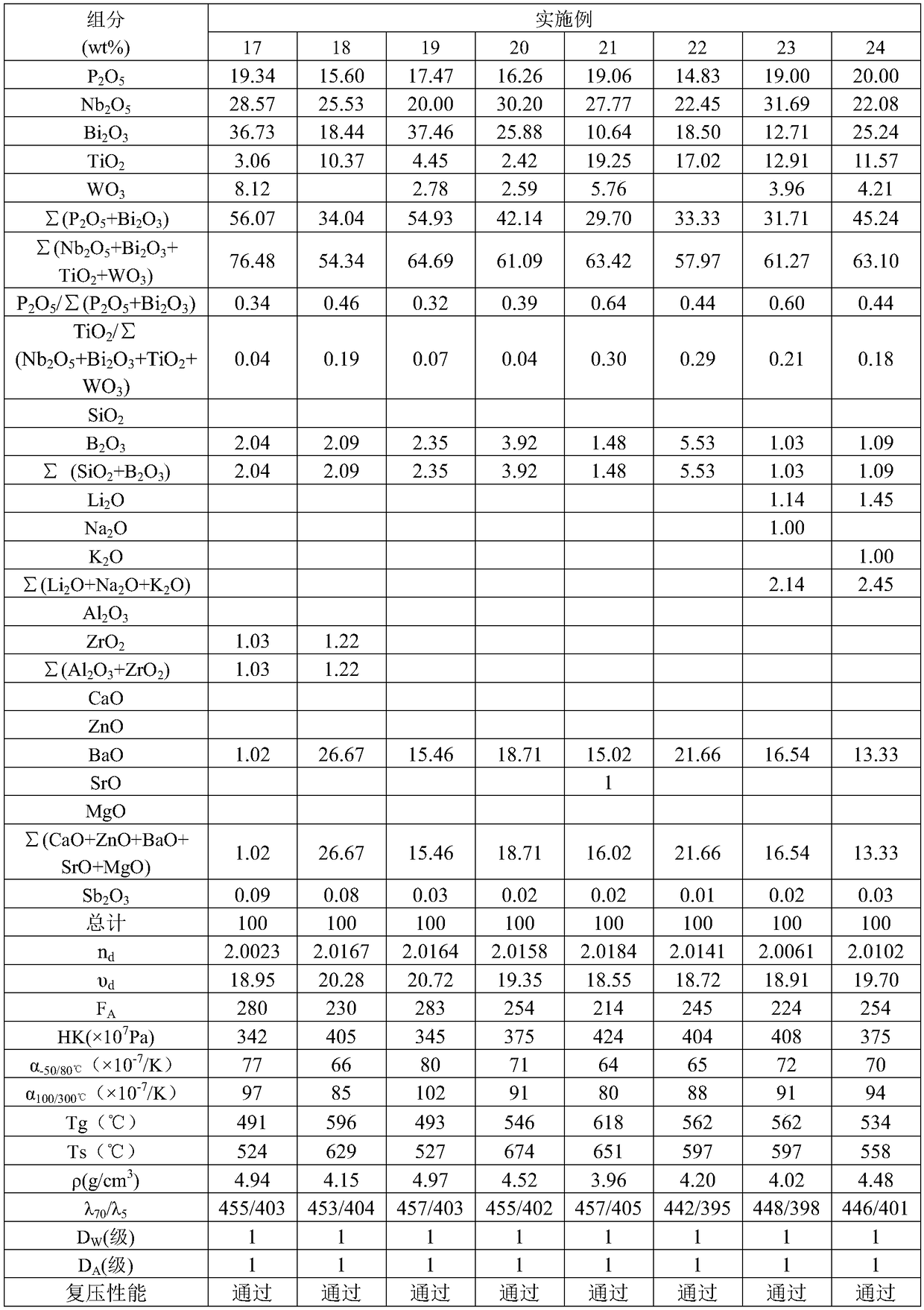

[0118] The components of Examples 1-56 in Tables 1-7 are weighed in proportion and mixed uniformly to make a batch, and the prepared batch is put into a quartz or corundum crucible, at a temperature of 900-1350°C and Under an oxidizing atmosphere, melt and stir for 6-8 hours, then pour into water, drain and dry the poured broken glass, and then put it into a crucible mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com