Damping material and preparation method thereof as well as loudspeaker enclosure to which damping material is applied

A technology of sound-absorbing materials and molecular sieves, which is applied in the field of sound-absorbing materials, can solve the problems of low speaker performance stability, speaker performance degradation, and easy adsorption of organic matter, etc., and achieve the effects of improving low-frequency acoustic performance, improving low-frequency effects, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

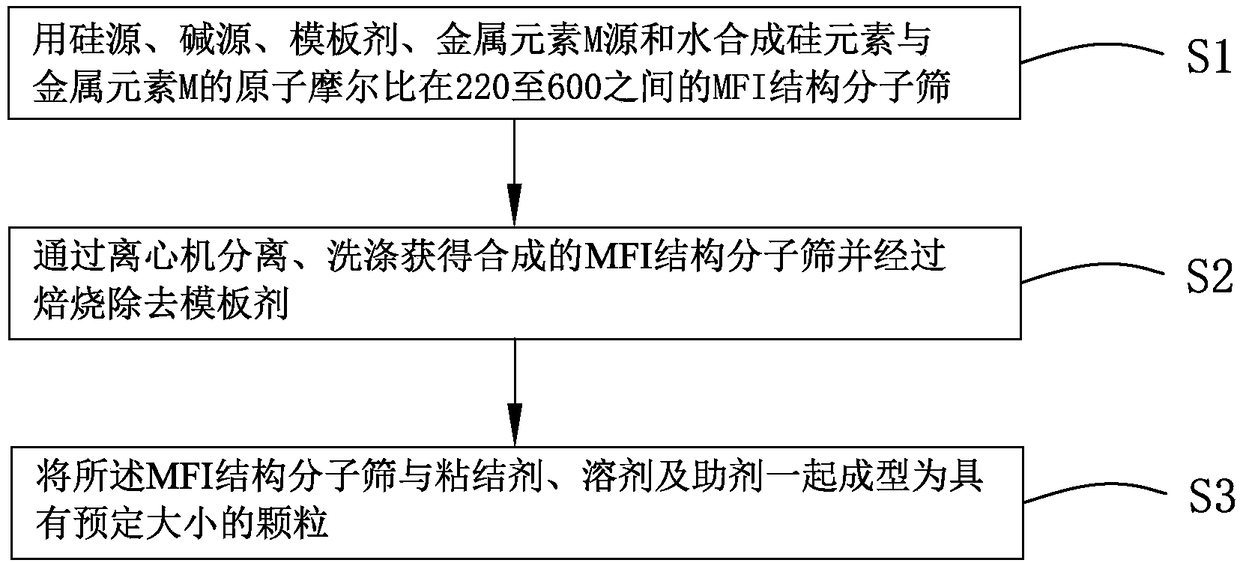

[0030] The present invention also provides the preparation method of the above-mentioned sound-absorbing material, the specific process is as follows figure 1 shown.

[0031] Step S1: Using a silicon source, an alkali source, a template agent, a metal element M source, and hydration to synthesize an MFI molecular sieve with an atomic molar ratio of silicon element to metal element M between 220 and 600.

[0032] In this step, when the effect is optimal, a molecular sieve with an MFI structure in which the atomic molar ratio of silicon element to metal element M is between 250 and 500 is synthesized; more preferably, a molecular sieve with an MFI structure between 280 and 450 is synthesized.

[0033] Regarding step S1, specifically, the source of the metal element M is described by taking the aluminum source as an example. The synthetic raw materials (silicon source, aluminum source, template agent, alkali source, etc.) The reaction obtains molecular sieve powder with MFI stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com