Device and method for removing impurities in mercury-containing crude selenium

A crude selenium and oxidation furnace technology is applied in the preparation of selenium/tellurium, binary selenium/tellurium compounds, selenium/tellurium oxides/hydroxides, etc. high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

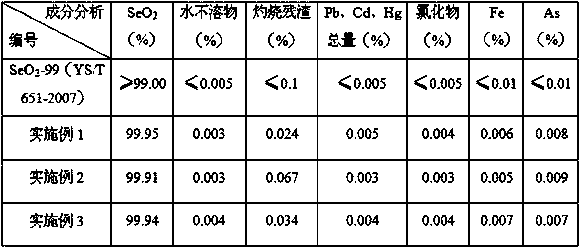

Embodiment 1~3

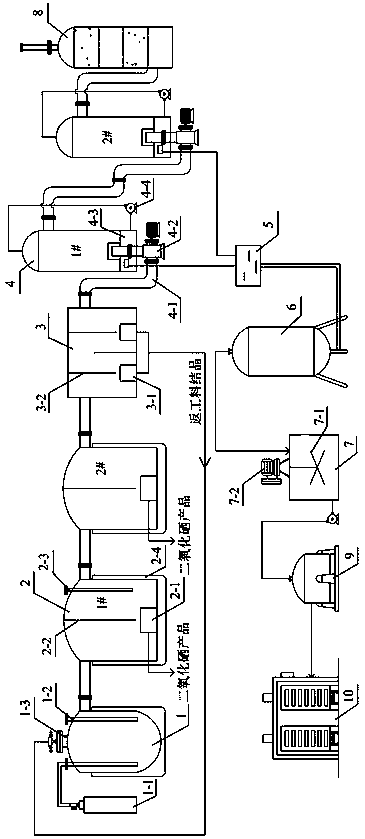

[0066] Embodiments 1 to 3 of the device of the present invention are as figure 1 As shown, it includes oxidation furnace 1, 1# and 2# crystallizer 2, separator 3, 1# and 2# spray tower 4, filter 5, ion exchange column 6 and reduction tank 7; The top is provided with an oxygen delivery device 1-1 and a temperature measuring device 1-2, and the air outlet on the top of the oxidation furnace 1 is connected to the air inlet on the top of the 1# crystallizer 2; The air inlet on the crystallizer 2 top is connected; the air outlet on the 2# crystallizer 2 top is connected with the air inlet on the separator 3 top; the bottom of the 1# and 2# crystallizer 2 is provided with a discharge port 2-1; The air outlet of the separator 3 is connected to the air inlet at the bottom of the 1# spray tower 4 through the water sealer 4-1 and the induced draft fan 4-2; the water tank 4 at the bottom of the 1# and 2# spray tower 4- 3 Connect the tops of the 1# and 2# spray towers 4 through the spray...

Embodiment 1

[0069] Put 5kg of mercury-containing crude selenium in the oxidation furnace 1, seal it, first heat the 1# and 2# crystallizer 2 to 260 °C, stop heating the 1# and 2# crystallizer 2, and then heat the oxidation furnace 1, when the oxidation After the temperature of furnace 1 reaches 100°C, oxygen is supplied to oxidation furnace 1 through oxygen cylinder 1-1, the output pressure of oxygen supply is 0.25MPa, the flow rate is 2.5L / min, and the induced draft fan 4-2 of spray tower 4 is started at the same time and spray pump 4-4, when the temperature of oxidation furnace 1 reaches 350°C, heat preservation reaction for 1.5h, then further heat oxidation furnace 1 to 550°C, increase the oxygen flow rate to 12L / min at the same time, heat preservation reaction for 4.5h, when When the temperature in 1# and 2# crystallizer 2 is ≤250℃, stop heating the oxidation furnace 1, the oxygen flow rate is reduced to 2.5L / min, and cool naturally for 7 hours. When the temperature in the oxidation fu...

Embodiment 2

[0071]Put 5kg of mercury-containing crude selenium in the oxidation furnace 1, seal it, first heat the 1# and 2# crystallizer 2 to 300 °C, stop heating the 1# and 2# crystallizer 2, and then heat the oxidation furnace 1, when the oxidation After the temperature of the furnace 1 reaches 120°C, oxygen is supplied to the oxidation furnace 1 through the oxygen cylinder 1-1, the output pressure of the oxygen supply is 0.3MPa, and the flow rate is 2L / min. At the same time, the induced draft fan 4-2 and the Spray pump 4-4, when the temperature of oxidation furnace 1 reaches 400°C, heat preservation reaction for 1h, then further heat oxidation furnace 1 to 600°C, at the same time increase the oxygen flow rate to 10L / min, heat preservation reaction for 5h, when 1# and When the temperature in 2# crystallizer 2 is ≤250°C, stop heating the oxidation furnace 1, reduce the oxygen flow rate to 2L / min, and let it cool naturally for 8 hours. When the temperature is less than or equal to 100°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com