A battery swapping device for an electric vehicle

A technology for electric vehicles and vehicles, which is applied in the direction of electric vehicles, electric power devices, power devices, etc., and can solve the problems of no way to automatically replace the car's rechargeable battery and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

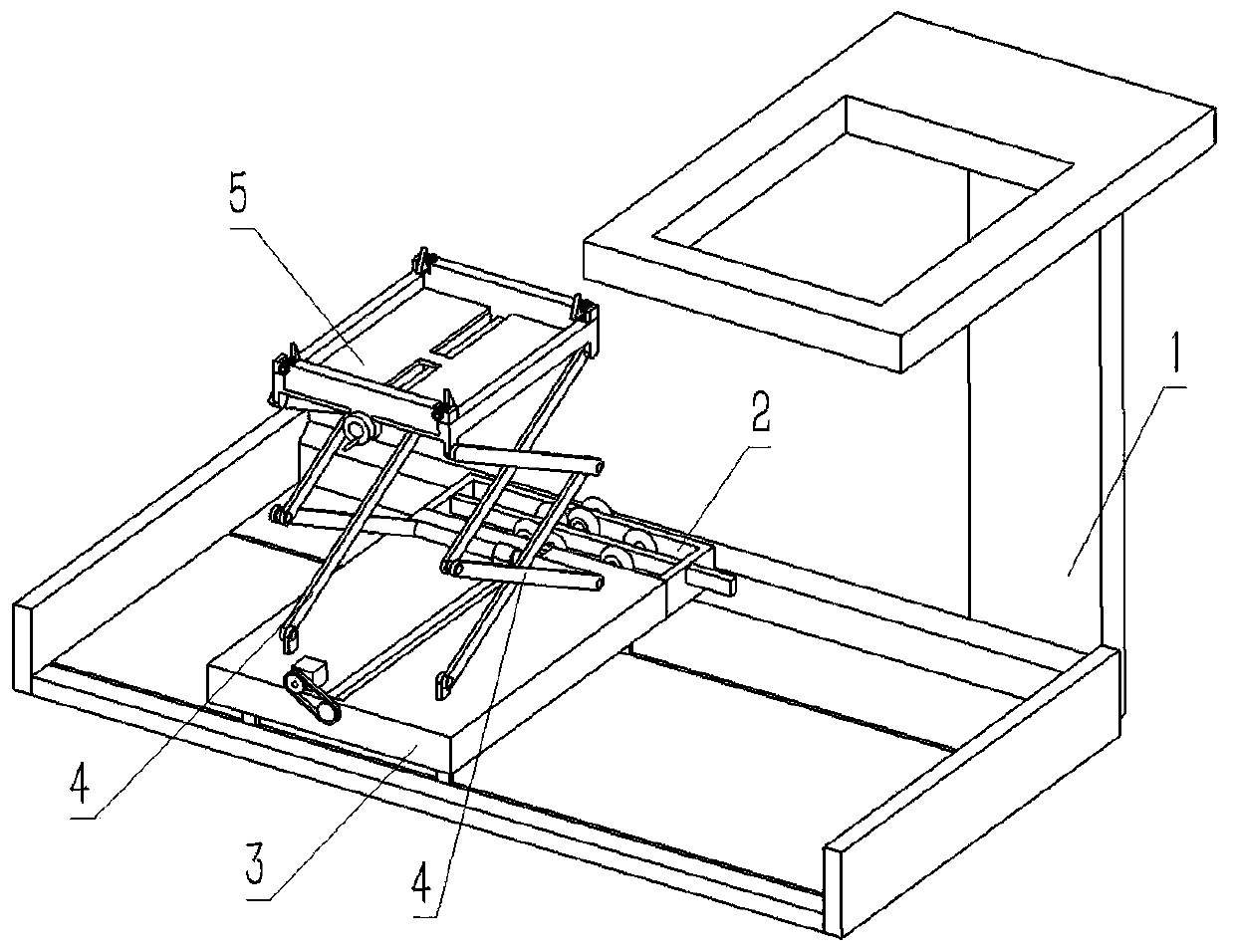

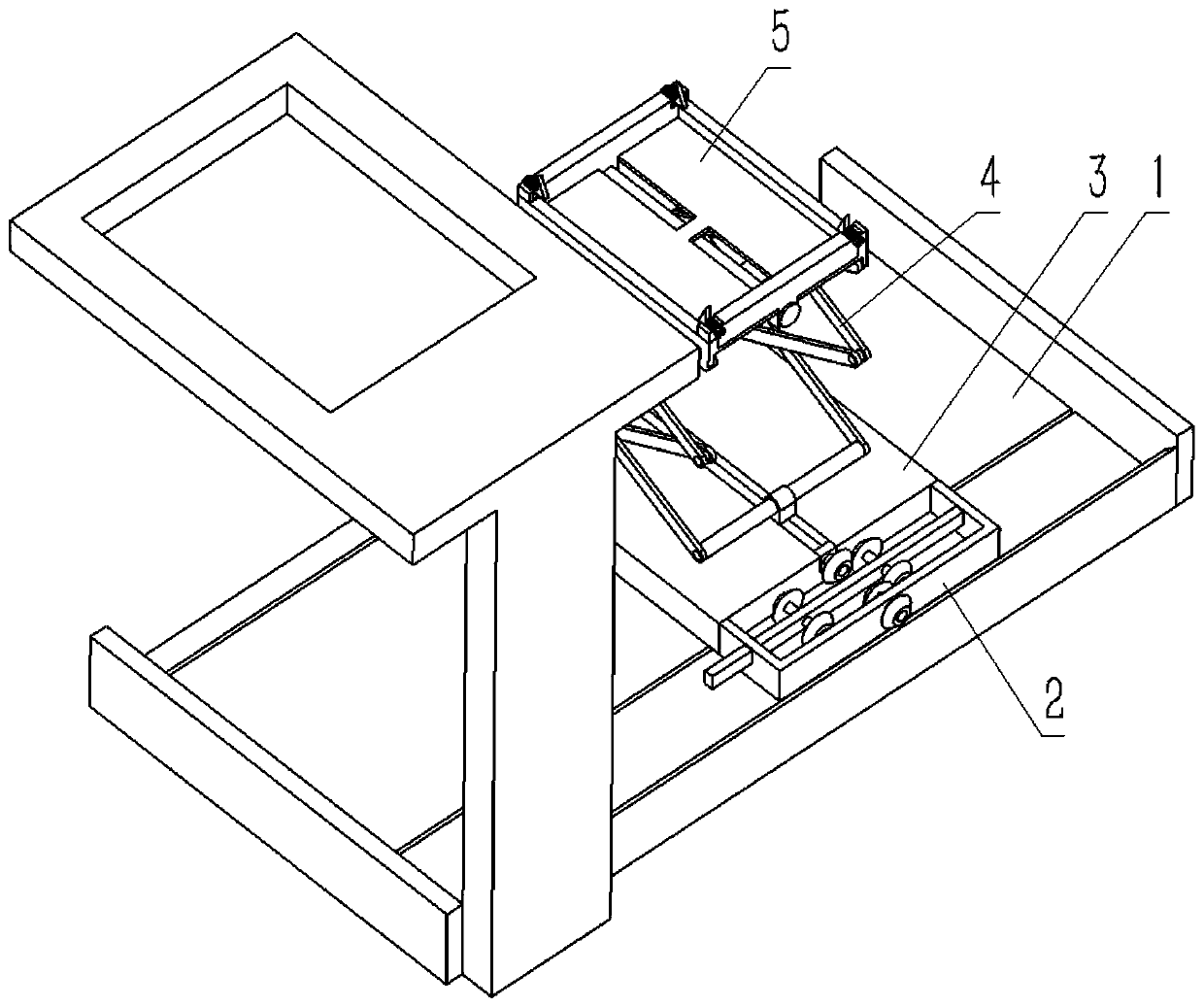

[0036] Combine below Figure 1-18 Describe this embodiment, an electric vehicle power exchange device, including a vehicle bracket 1, a sliding transmission combination 2, a sliding plate 3, two truss structures 4 and a bearing combination 5, the sliding transmission combination 2 includes an outer frame 2-1 , Rectangular slider 2-2, bevel gear Ⅰ2-3, transmission shaft Ⅰ2-4, bevel gear Ⅱ2-5, bevel gear Ⅲ2-6, transmission shaft Ⅱ2-7, bevel gear Ⅳ2-8, output bevel gear 2-9 , output transmission shaft 2-10, transmission bevel gear 2-11, rotating hole 2-12, two rectangular sliding holes 2-13 and two rectangular rod rotating holes 2-14, rotating hole 2-12 is arranged on the outer frame 2- 1. At the rear end of the inner wall, two rectangular sliding holes 2-13 are respectively arranged at the left and right ends of the inner wall of the outer frame 2-1. The inner end of the outer frame 2-1 is hollowed out, and two rectangular rods are arranged on the rectangular sliding rod 2-2. R...

specific Embodiment approach 2

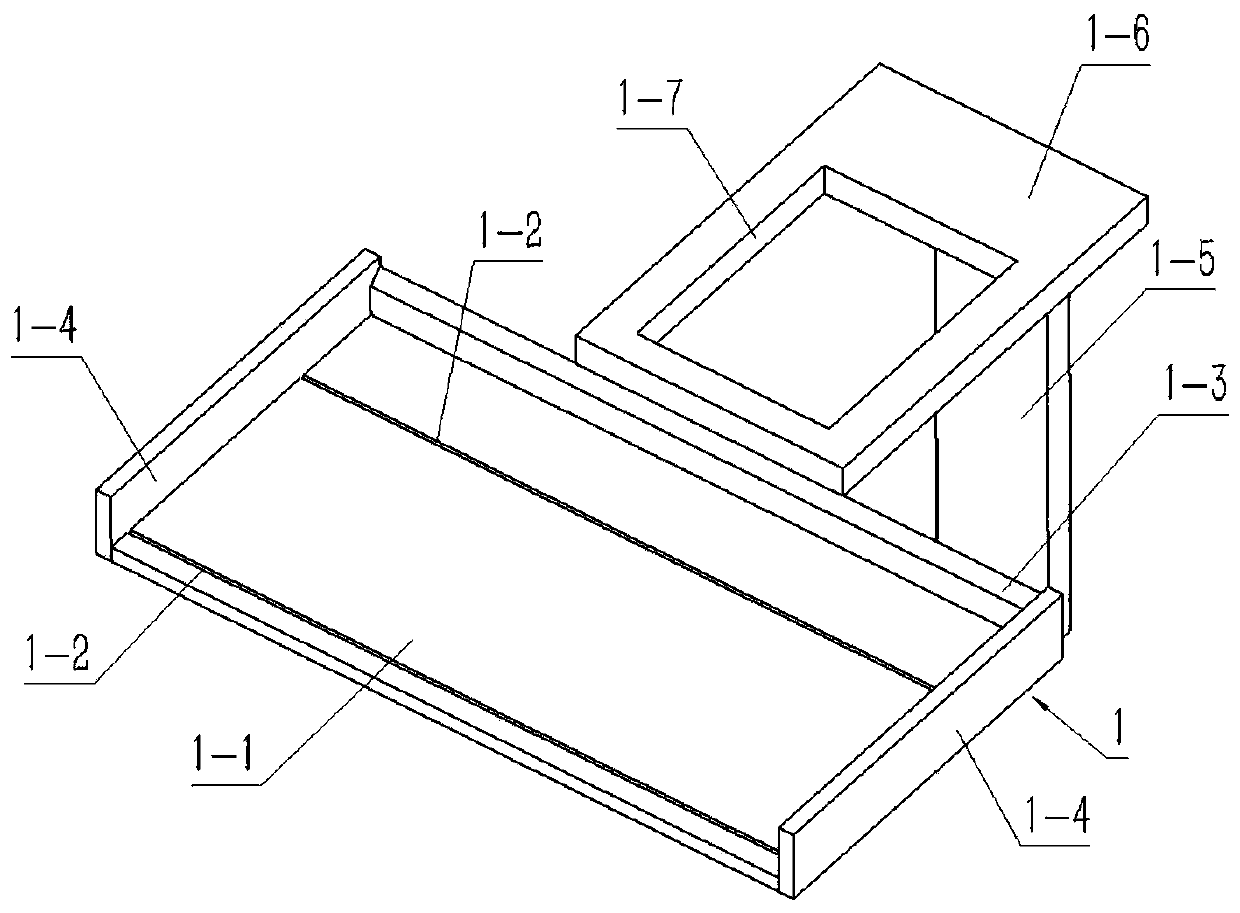

[0045] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the first embodiment, the vehicle bracket 1 includes a bottom plate 1-1, two rectangular chute 1-2, an inclined rack plate 1-3, two end plates 1- 4. The support rod 1-5, the upper plate 1-6 and the rectangular through hole 1-7, the two rectangular chute 1-2 are evenly arranged on the upper end surface of the bottom plate 1-1, and the inclined rack plate 1-3 is fixedly connected to the The rear end of the base plate 1-1, the two end plates 1-4 are respectively fixedly connected to the left and right ends of the base plate 1-1, the pole 1-5 is fixedly connected to the right side of the rear end surface of the base plate 1-1, and the upper plate 1- 6 is fixedly connected to the upper end of the pole 1-5, and the rectangular through hole 1-7 is arranged on the upper plate 1-6;

[0046] The bottom plate 1-1 can be conveniently provided with two rectangular chute 1-2; the two rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com