Production line of intelligent refrigerator door seal

A smart refrigerator and production line technology, applied in lighting and heating equipment, household appliances, household refrigeration equipment, etc., can solve the problems of slow cutting speed, slow welding speed, low production efficiency, etc., to reduce cooling time, slow welding speed, The effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

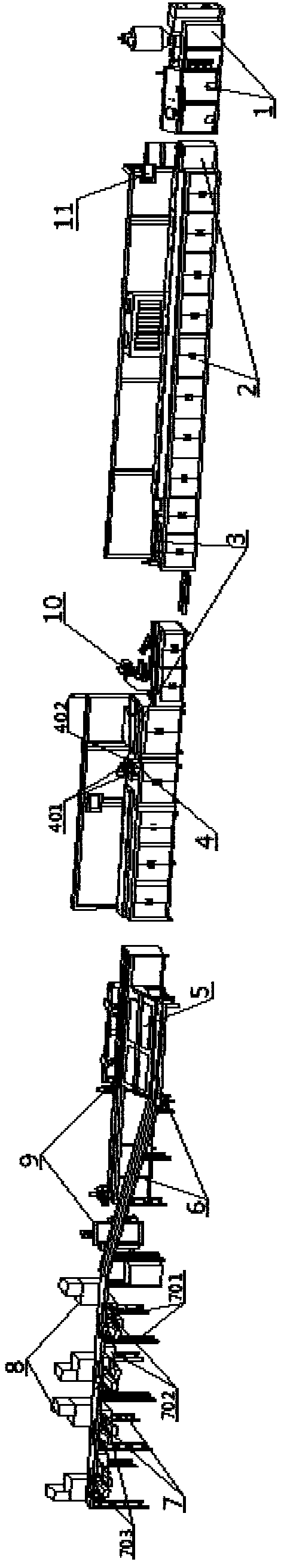

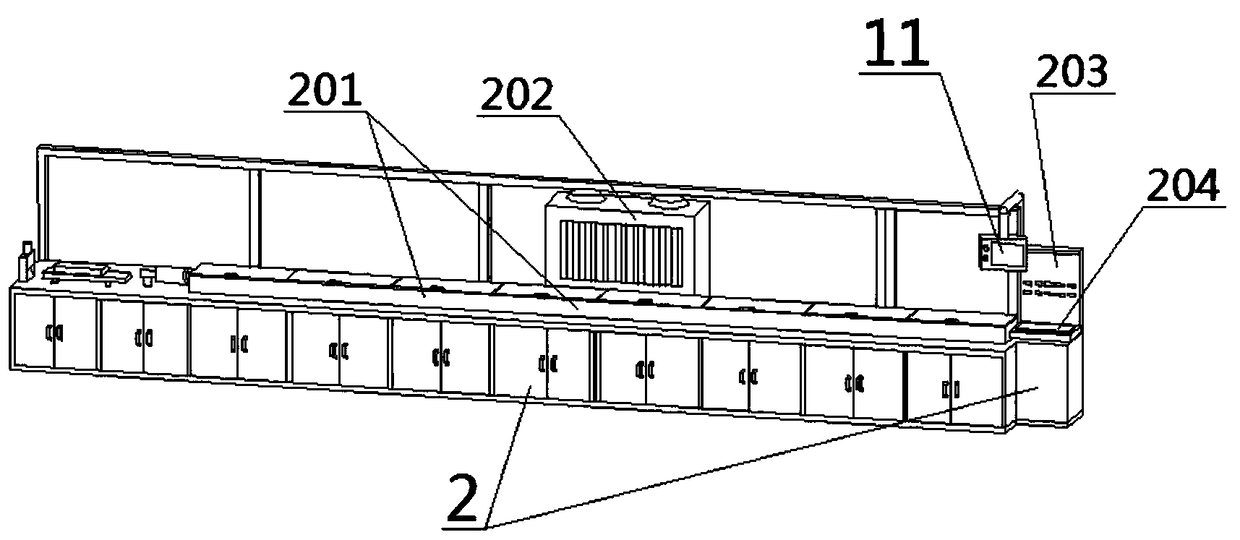

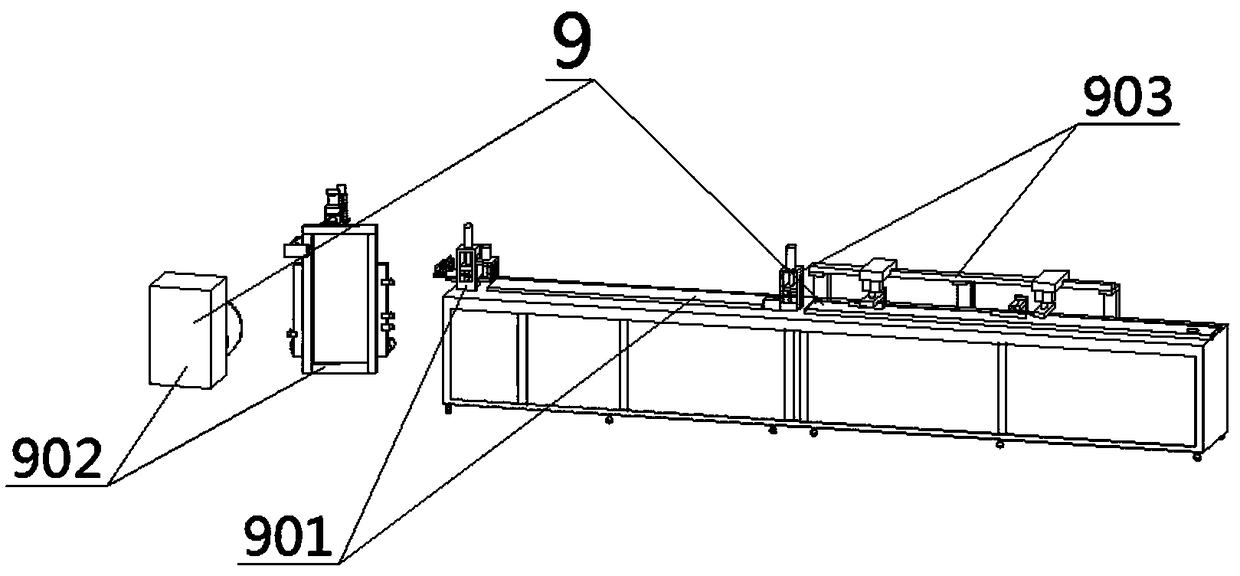

[0013] See accompanying drawing: a kind of intelligent refrigerator door seal production line, it is characterized in that comprising extruder (1), cooling device (2), tractor (3), punching machine (10), cutting device (4), wear magnetic device (9), inclined plane guide transmission device (5), conveyor belt (6), distribution device (7), welding device (8) and control device (11), the extruder (1) is installed at the beginning of the production line, extruding The cooling device (2) tractor (3) punching machine (10) cutting device (4) magnetic threading device (9) is installed on the left side of the machine (1) in turn, and the inclined plane guide transmission device (5) is installed on the magnetic threading device (9) ), one end of the conveyor belt (6) is connected to the inclined plane guide transmission device (5) and the other end is connected to the distribution device (7), the welding device (8) is installed behind the distribution device (7), and the cooling device (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com