Solar two-traction wire separating structure for wire drawing machine for sunshade net

The technology of a wire drawing machine and a sunshade net is applied in the field of the solar two-stretching wire structure, which can solve the problems such as the inability to guarantee the quality of the flat wire, and achieve the effects of ensuring the stretching temperature and quality, ensuring the quality, and preventing the breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

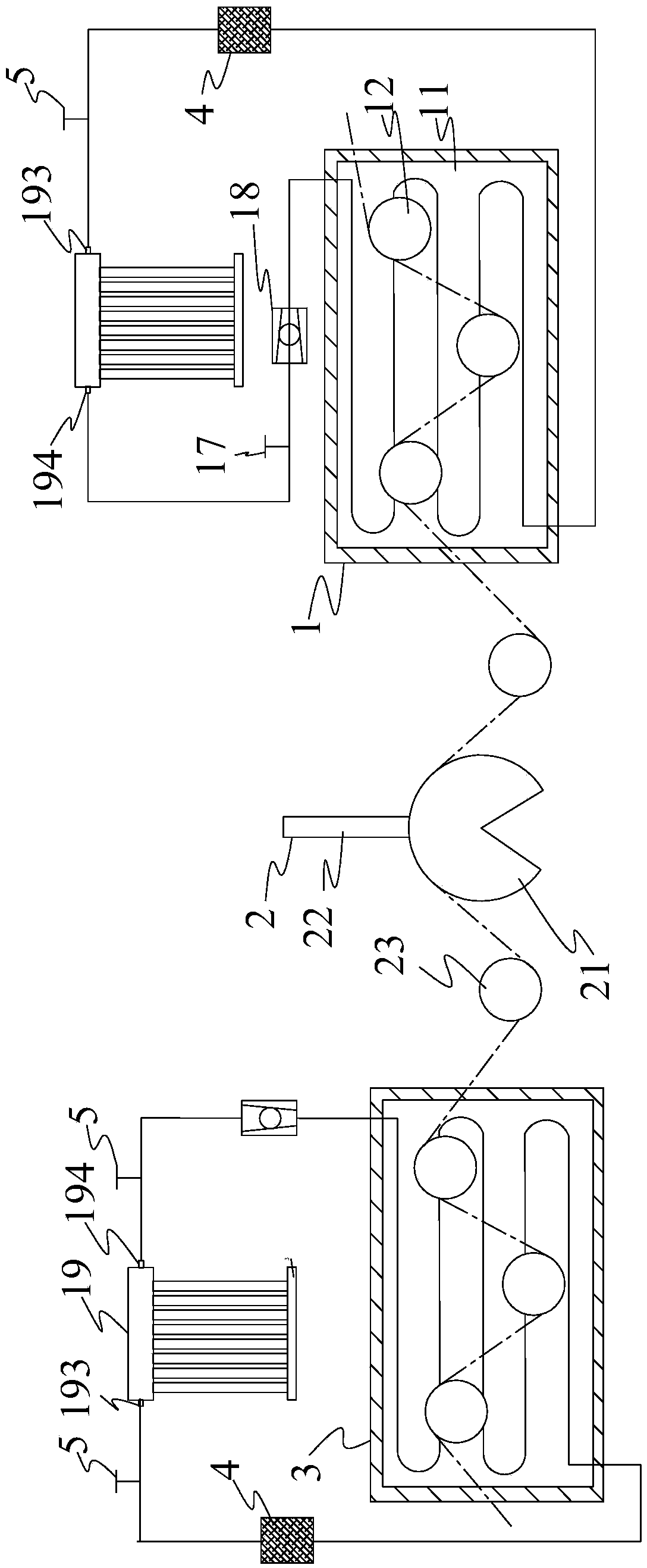

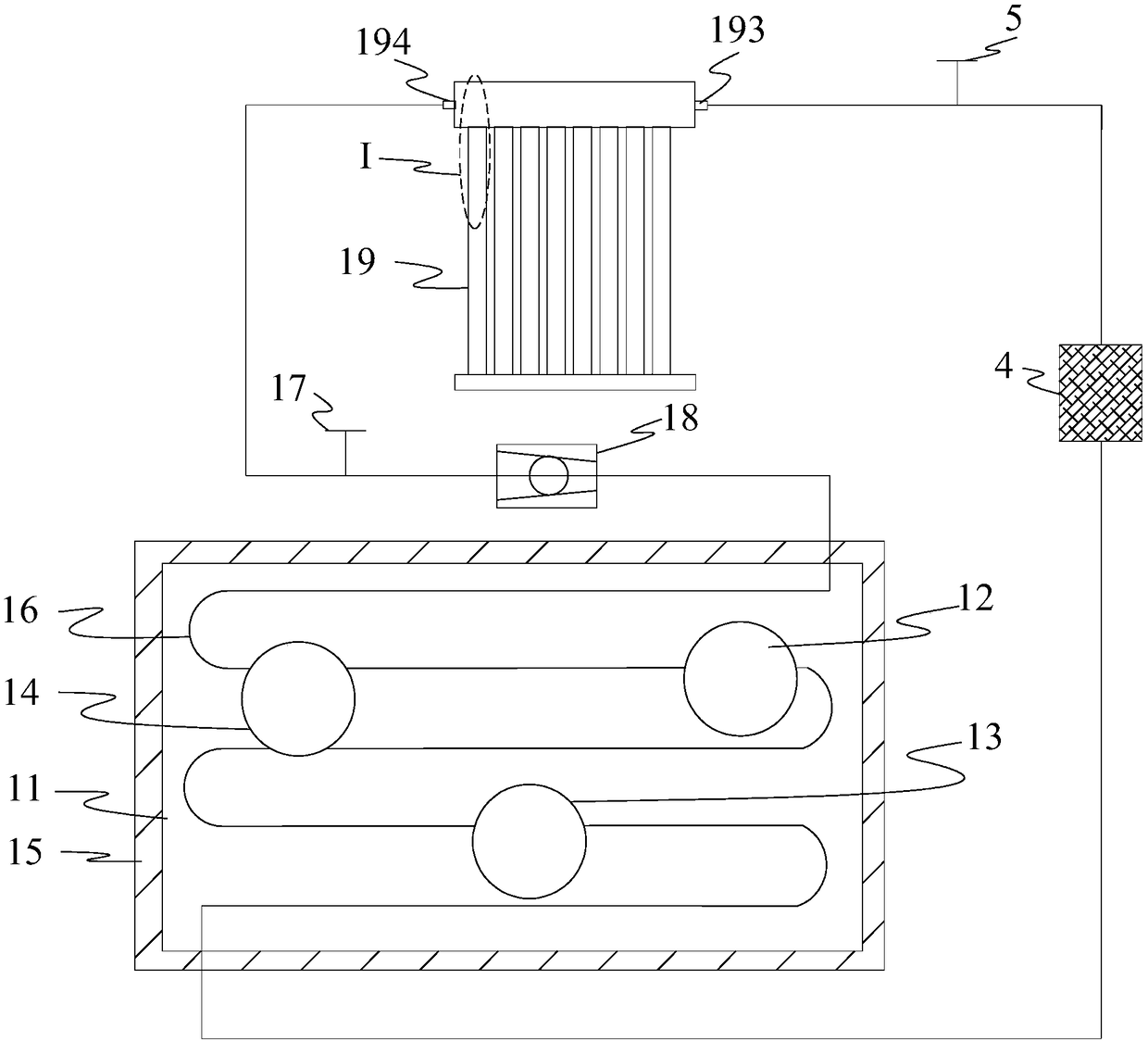

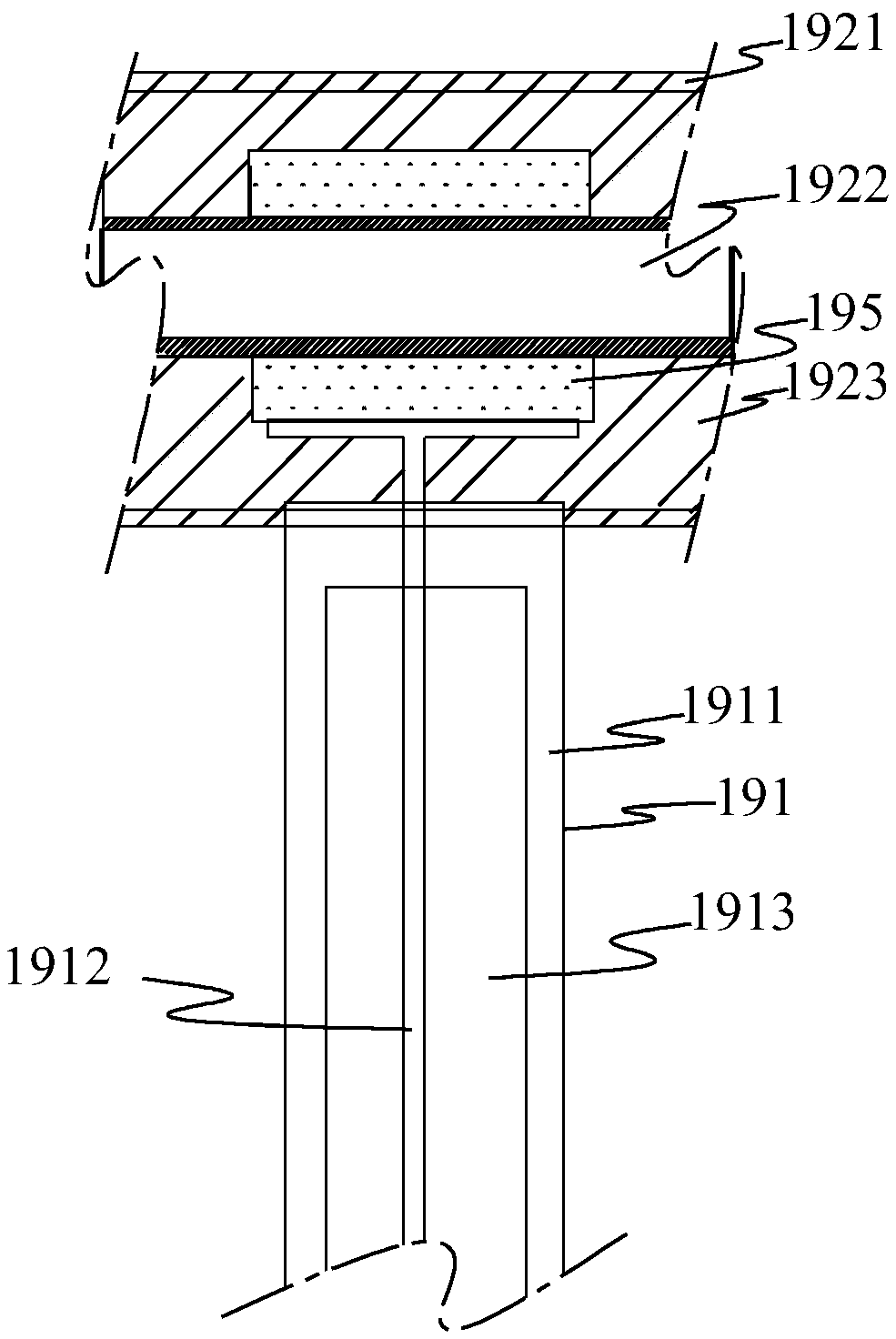

[0024] Such as Figure 1 to Figure 3 The solar two-drawing and splitting structure for the sunshade net wire drawing machine shown includes a first drawing heat oven 1, a splitting device 2 matched with the first drawing heat oven 1 and a second drawing heat oven 3 matched with the splitting device 2 . The first drawing heat oven 1 and the second drawing heat oven 3 have the same structure. The first drawing heat oven 1 comprises the box body 11 that the flat bar that comes out from a drawing split wire structure passes through, the first drawing roller 12 that is located in the casing, the second drawing roller 13, the 3rd drawing roller 14, be located at The insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com