Production process and production equipment of slimming cotton fiber

A production equipment and cotton fiber technology, which are applied to the production process of slimming cotton fiber and the field of production equipment, can solve the problems of poor tow bulkiness, stiff silk, insufficient crimping performance of raw silk, etc., and achieve good shaping effect and reduce Energy consumption, energy saving effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

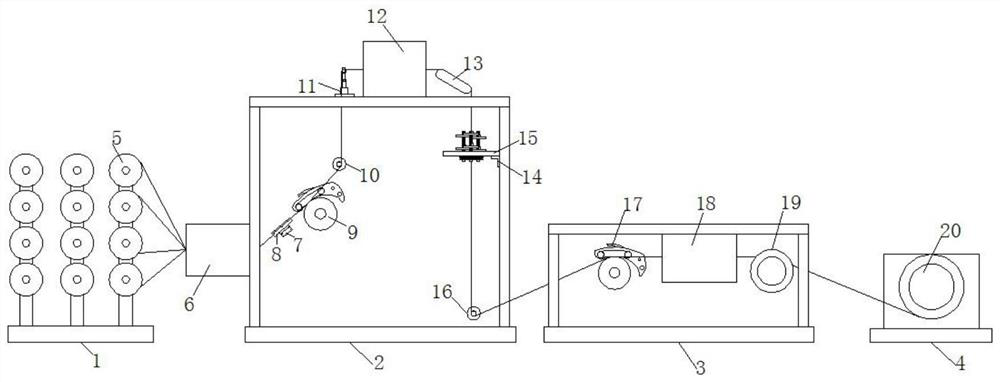

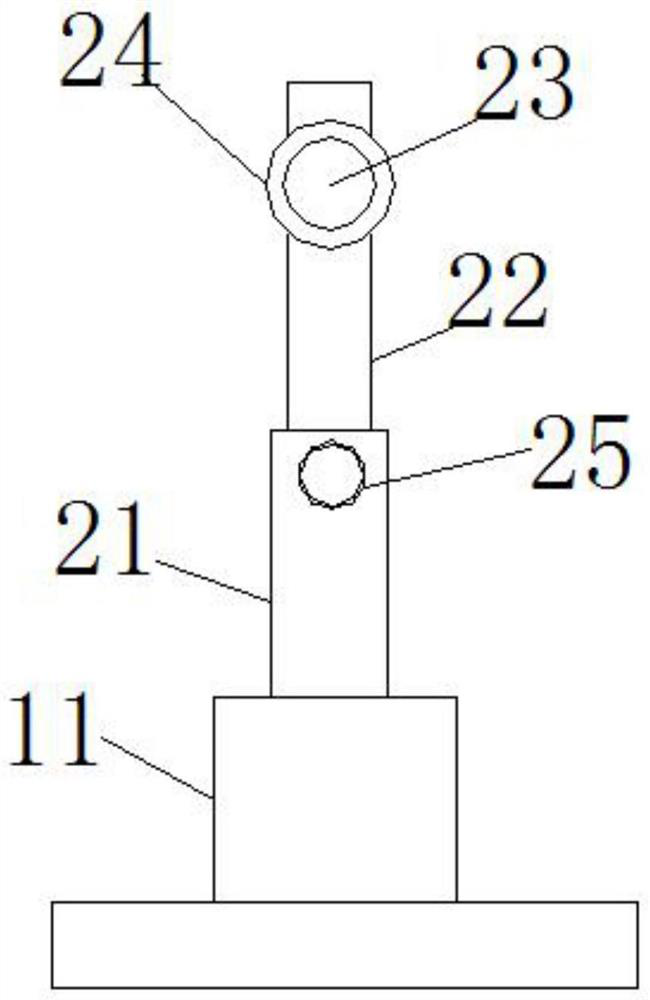

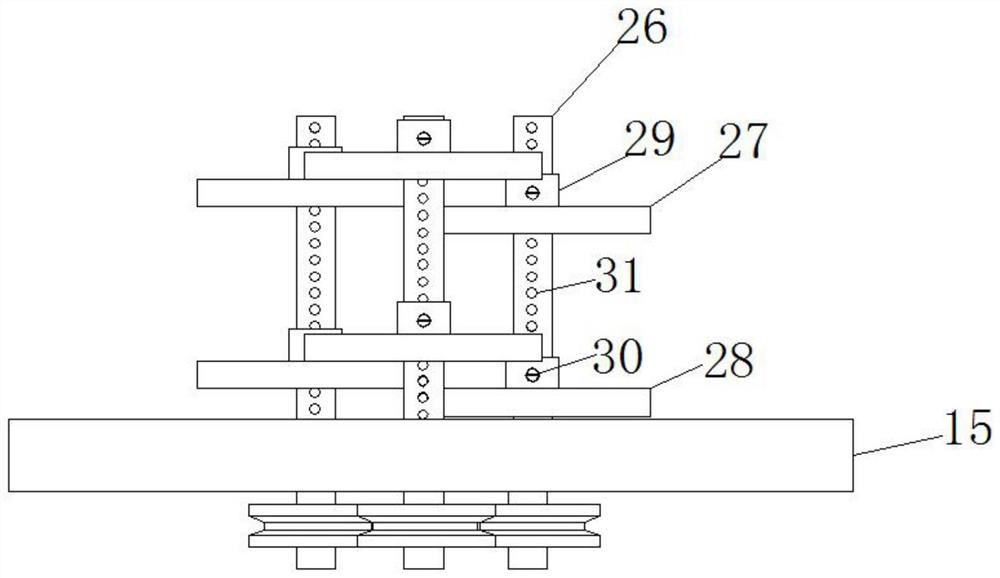

[0032] like Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a production equipment for slimming cotton fibers, including a first frame 1, a second frame 2, a third frame 3 and a fourth frame 4; fixedly connected to the upper wall of the first frame 1 The pre-network device 6 is fixedly connected to the side of the second frame 2 facing the first frame 1; the first bracket 7 is fixedly connected to the inner and rear walls of the second frame 2 The wire moving plate 8, the upper wall of the wire moving plate 8 is provided with a groove, and the inner side wall of the groove is provided with a wire blocking assembly for blocking the wire. The guide rod 34 is slidably connected to the inner side wall of the groove of the wire moving plate 8. Between the two sets of baffles 32 and the inner side wall of the groove, there are also adjusting screws 33 for adjusting the distance. The two adjusting screws 33 penetrate through the front of the wire movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com