Frame part manufacturing fixture and fixing method thereof

A technology of parts and frame, which is applied in the field of fixing tooling and fixing of frame parts, can solve the problems of difficult size control, low production efficiency, and difficult control of product quality, etc., to solve the inconvenience of manual production, easy maintenance and replacement, The effect of solving the difficulty of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

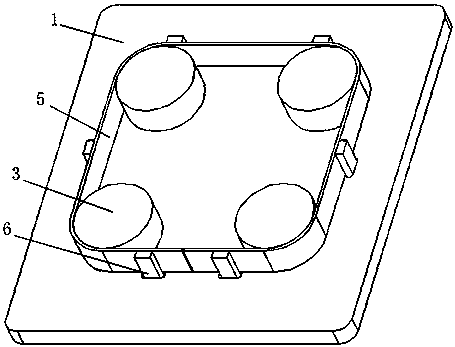

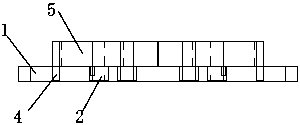

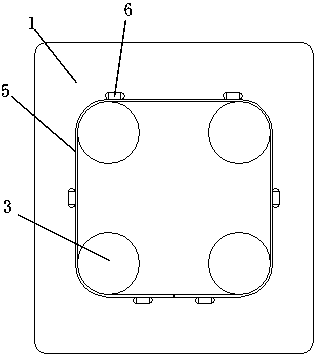

[0024] see Figure 1-Figure 7 , the present embodiment provides a frame-shaped part fixing tool, including a bottom plate 1, four light holes 2 are symmetrically arranged on the bottom plate 1 with the center of the bottom plate as a symmetrical center, and the small head end 3-2 of the round rod 3 is sleeved on the light hole 2 , the four light holes 2 are provided with several waist-shaped holes 4 for installing the baffle 6, and the arcs of the four corners of the frame-shaped part 5 are matched with the arcs of the big end 3-1 of the round rod 2 , the side wall of the frame-shaped part 5 is tangent to the big end 3-1 of the adjacent round rod 2.

[0025] The diameter of the small end 3-2 of the round rod 3 is the same as the diameter of the light hole 2, and its height is less than the depth of the light hole 2 on the base plate. The circular arc diameters are the same, and its height is equal to the wall width of the frame part 5.

[0026] The centers of the four light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com