Internet of things grinding wheel

An Internet of Things, grinding wheel technology, applied in the direction of bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problem of difficulty in obtaining the running status of the grinding wheel immediately, reduce time and efficiency costs, prevent power consumption, and eliminate information asymmetry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

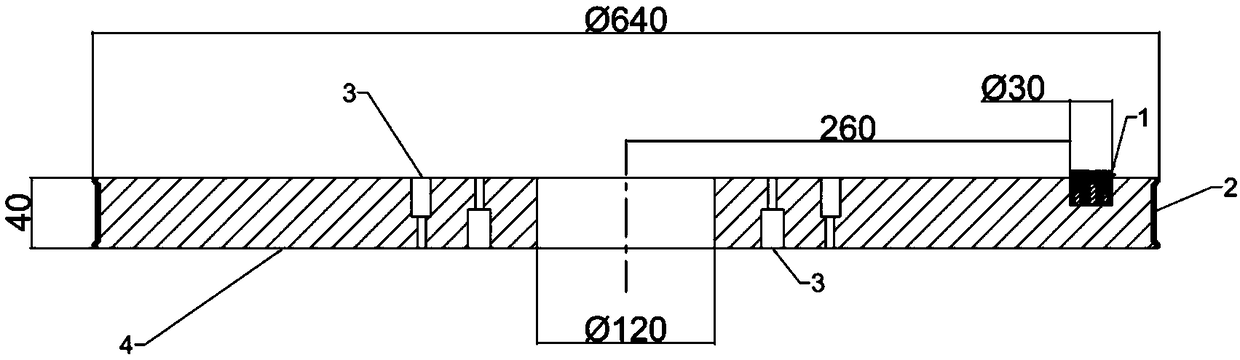

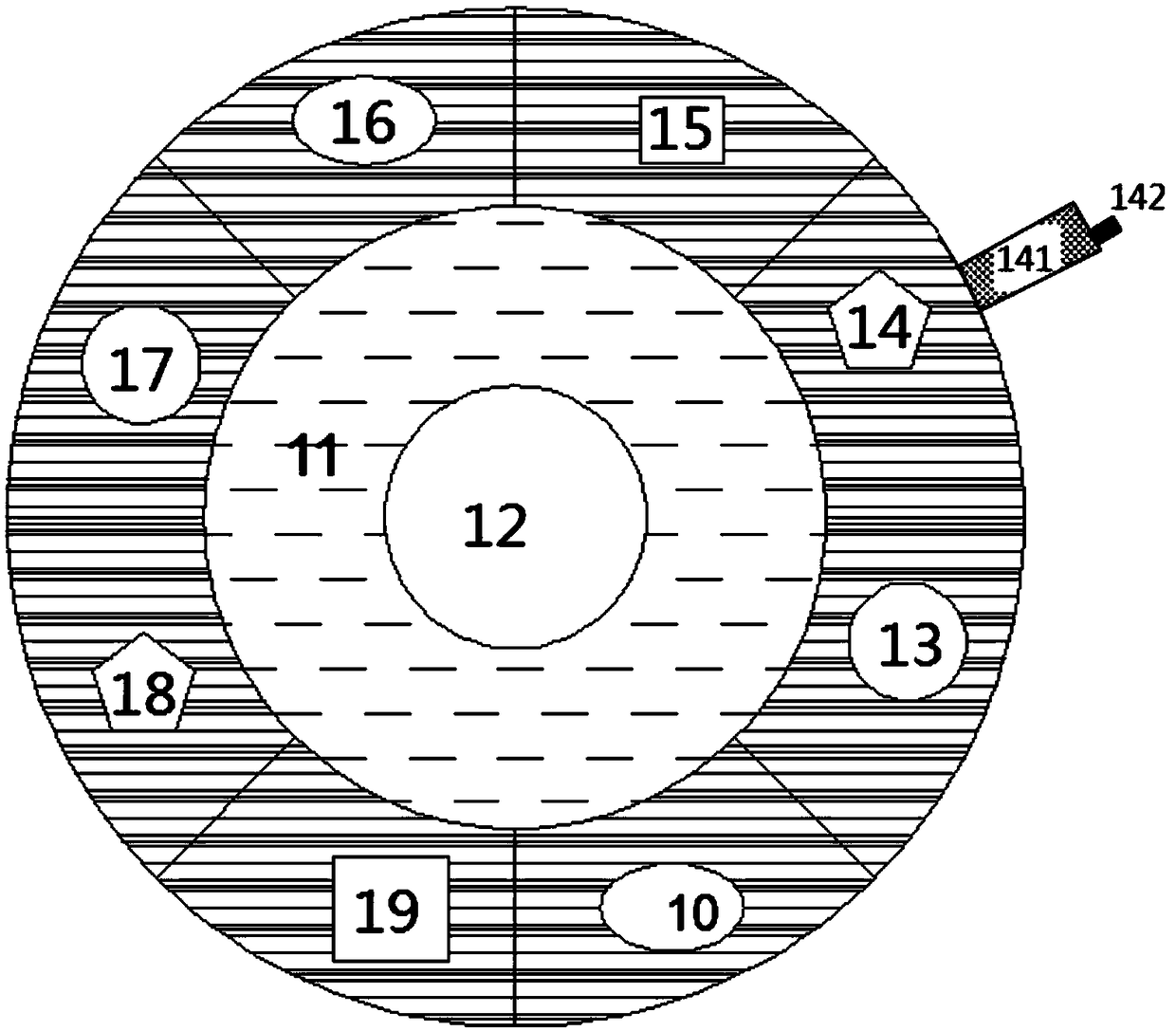

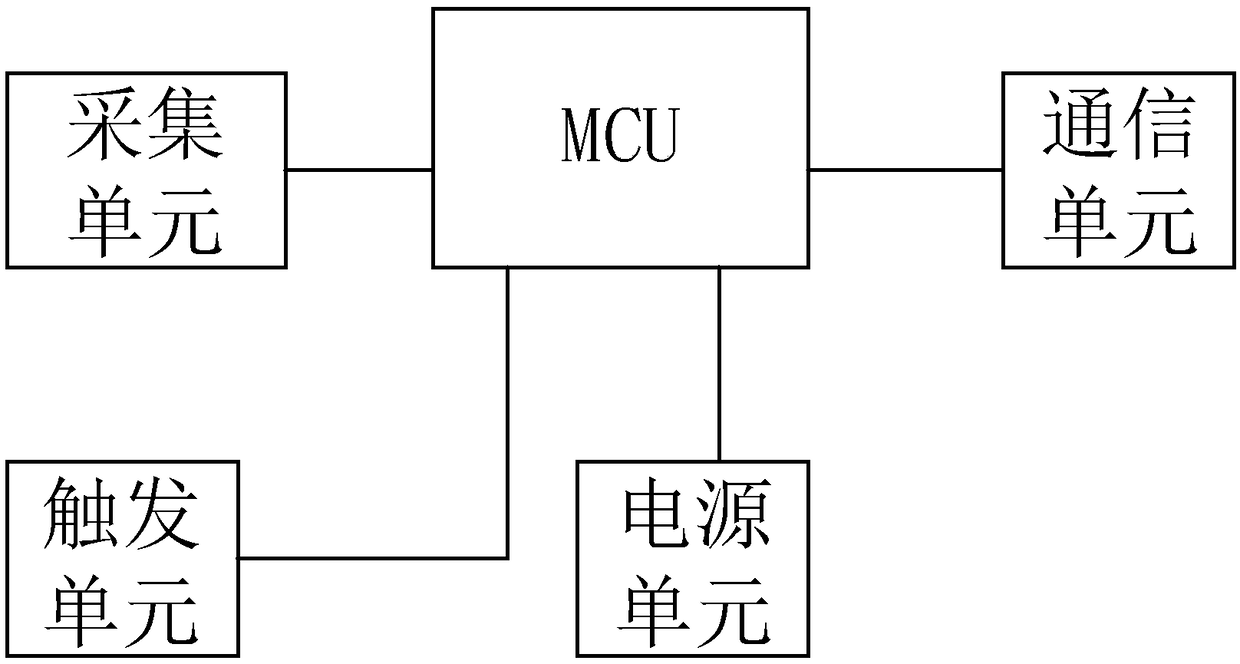

[0021] Such as figure 1 As shown, a grinding wheel capable of network sensing and online detection of the present invention includes an Internet of Things device 1 , an abrasive layer 2 , a positioning hole 3 , and a grinding wheel base 4 . The grinding wheel is to implant the Internet of Things device 1 into the grinding wheel base 4. The superhard grinding wheel is to open a blind hole in the non-working layer on the surface of the metal base. The IoT device is embedded in the hole, and then the edge of the hole is sealed with colloid; the general grinding wheel A custom-made mold is used to reserve a blind hole for fixing the Internet of Things device at the end surface. After the grinding wheel is pressed and sintered, the Internet of Things device is embedded in it, and finally the edge of the hole is sealed with colloid. The IoT device transmits the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com