Polymer film for treating high-salt wastewater and preparation method thereof

A technology for polymer membranes and high-salt wastewater, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, membranes, etc., can solve the problems of mechanical properties that need to be further improved, complex preparation processes, and poor corrosion resistance , to achieve the effects of low equipment dependence, excellent mechanical properties, and good anti-fouling and salt-resistance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

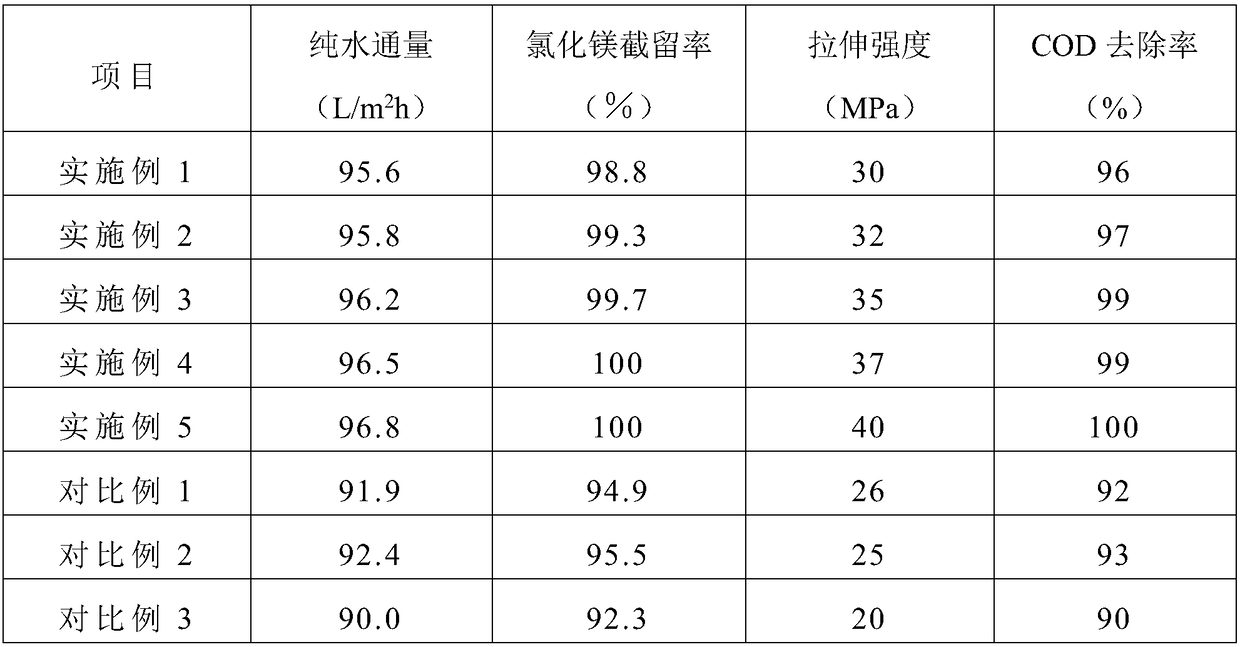

Examples

Embodiment 1

[0030] A method for preparing a polymer membrane for high-salt wastewater treatment, comprising the steps of:

[0031] Ⅰ Preparation of fluorine-containing piperazine amide polycondensate: Dissolve 10 g of piperazine-2-carboxamide and 24.3 g of 1,4-bis(2',3'-epoxypropyl) perfluorobutane in dimethyl ethylene Form a solution in 100g of sulfone, then add 2g of potassium carbonate to the solution, stir and react at 90°C for 8 hours, then add 4,6-bis(2,2,2-trifluoroethoxy)-1, 1g of 3,5-triazine-2-amine, continue to stir and react for 1 hour, then cool to room temperature, precipitate in water, wash the precipitated polycondensate with water for 3 times, then with ethanol for 4-6 times, and then vacuum drying in a drying oven at 70° C. for 12 hours to obtain a polycondensate of amides containing flupiperazine;

[0032] II Modified chitosan: Add 30g of chitosan, 5g of chloromethyltriethoxysilane, and 5g of potassium carbonate to 90g of chloroform, stir and react at 50°C for 4 hours,...

Embodiment 2

[0037] A method for preparing a polymer membrane for high-salt wastewater treatment, comprising the steps of:

[0038]Ⅰ Preparation of fluorine-containing piperazine amide polycondensate: Dissolve 10 g of piperazine-2-carboxamide and 24.3 g of 1,4-bis(2',3'-epoxypropyl)perfluorobutane in N,N - Form a solution in 110g of dimethylformamide, then add 3g of sodium carbonate to the solution, stir and react at 93°C for 8.5 hours, then add 4,6-bis(2,2,2-trifluoroethoxy Base)-1,3,5-triazine-2-amine 1g, continue stirring for 1.2 hours, then cool to room temperature, precipitate in water, wash the precipitated polycondensate with water 4 times, and then with ethanol 5 times, As for drying at 73° C. in a vacuum oven for 13 hours, the amide polycondensate containing fluoperazine was obtained;

[0039] II Modified Chitosan: Add 35g of chitosan, 5g of chloromethyltriethoxysilane, and 5g of potassium carbonate to 100g of acetonitrile, stir and react at 53°C for 4.5 hours, remove the solvent...

Embodiment 3

[0044] A method for preparing a polymer membrane for high-salt wastewater treatment, comprising the steps of:

[0045] Ⅰ Preparation of fluorine-containing piperazine amide polycondensate: Dissolve 10 g of piperazine-2-carboxamide and 24.3 g of 1,4-bis(2',3'-epoxypropyl)perfluorobutane in N-formazine Form a solution in 125g of pyrrolidone, then add 3.5g of potassium hydroxide to the solution, stir and react at 95°C for 9 hours, then add 4,6-bis(2,2,2-trifluoroethoxy) - 1g of 1,3,5-triazin-2-amine, continue to stir and react for 1.6 hours, then cool to room temperature, precipitate in water, wash the precipitated polycondensate 5 times with water, then 6 times with ethanol, and then Drying in a vacuum drying oven at 75°C for 15 hours to obtain a polycondensate containing flupiperazine amides;

[0046] II Modified chitosan: Add 40g of chitosan, 5g of chloromethyltriethoxysilane, and 5g of potassium carbonate to 125g of acetone, stir and react at 56°C for 5 hours, remove the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com