Makeup removing lotion and preparation method thereof

A technology of makeup remover and oil-phase emulsifier, which is applied in the field of makeup remover and its preparation, can solve the problems of weak makeup remover ability, difficult removal, and inability to remove lipstick, etc., and achieves strong makeup removal ability, large surface area, and strong penetration and infiltration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

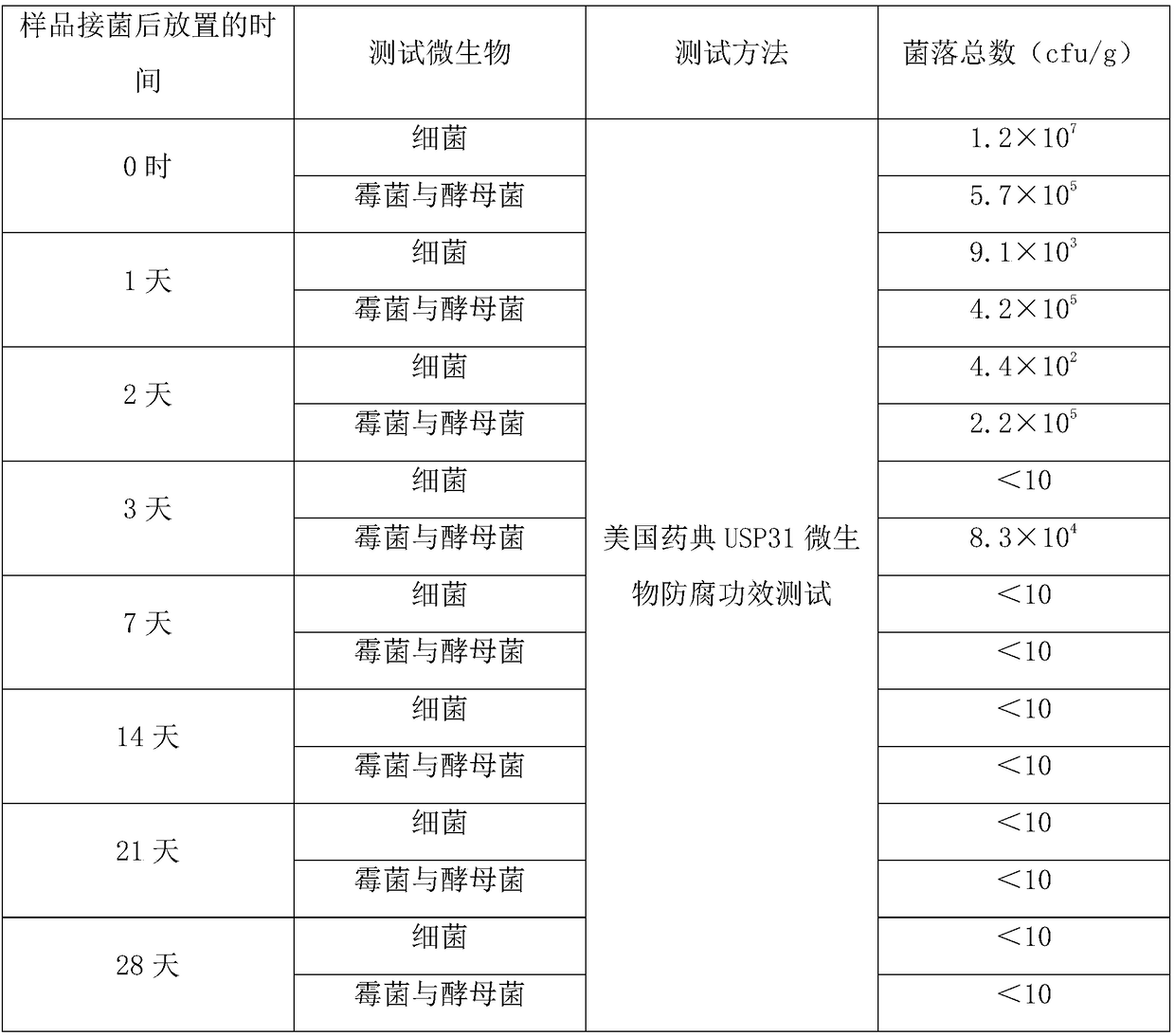

Embodiment 1

[0021] Take the following raw materials according to the following weight ratio: 12% cetyl ethyl hexanoate, 5.0% isononyl isononanoate, 3.0% isohexadecane, 0.05% 2,6-di-tert-butylhydroxytoluene, 18 % Sorbitol Polyoxyethylene Ether Tetraisostearate, 5.0% PEG-20 Glyceryl Triisostearate, 12% PEG-6 Caprylic / Capric Glycerides, 20% 1.3 Propylene Glycol, 0.1% EDTA-2NA , 0.02% citric acid, 0.08% sodium citrate, 0.2% 1,2-hexanediol, 0.5% caprylyl hydroxamic acid, 0.1% glyceryl caprylate, and the balance is water.

[0022] Among them, cetyl ethyl hexanoate, isononyl isononanoate, and isohexadecane are oils, 2,6-di-tert-butylhydroxytoluene is an antioxidant, polyoxyethylene sorbitol tetraisostearate Esters, PEG-20 glycerol triisostearate are oil phase emulsifiers, and the above oils, antioxidants and oil phase emulsifiers are all oil phase components;

[0023] PEG-6 caprylic / capric glycerides are water phase emulsifiers, 1.3 propylene glycol is a humectant, EDTA-2NA is a chelating agent...

Embodiment 2

[0028] Take the following raw materials according to the following weight ratio: 10% cetyl ethyl hexanoate, 5.0% isononyl isononanoate, 0.02% 2,6-di-tert-butylhydroxytoluene, 20% sorbitol polyoxyethylene ether Tetraisostearate, 8.0% PEG-20 Glyceryl Triisostearate, 12% PEG-6 Caprylic / Capric Glycerides, 15% 1.3 Propylene Glycol, 0.2% Tetrasodium EDTA, 0.02% Citric acid, 0.03% disodium hydrogen phosphate, 0.3% caprylyl hydroxamic acid, 0.2% glyceryl caprylate, and the balance is water.

[0029] Among them, cetyl ethyl hexanoate and isononyl isononanoate are oils, 2,6-di-tert-butylhydroxytoluene is an antioxidant, polyoxyethylene sorbitol tetraisostearate, PEG-20 Glyceryl triisostearate is an oil phase emulsifier, and the above oils, antioxidants and oil phase emulsifiers are all oil phase components;

[0030] PEG-6 caprylic / capric glycerides are water phase emulsifiers, 1.3 propylene glycol is a humectant, tetrasodium edetate is a chelating agent, citric acid and disodium hydrog...

Embodiment 3

[0033]Take the following raw materials according to the following weight ratio: 15% cetyl ethyl hexanoate, 6.0% isononyl isononanoate, 4.0% isohexadecane, 15% polyoxyethylene sorbitol tetraisostearate , 7.0% PEG-20 Glyceryl Triisostearate, 8.0% PEG-6 Caprylic / Capric Glycerides, 25% 1.3 Propylene Glycol, 0.15% EDTA-2NA, 0.05% Citric Acid, 0.1% Dipotassium Glycyrrhizinate, 0.2% 1,2-hexanediol, 0.4% caprylyl hydroxamic acid, 0.4% glyceryl caprylate, and the balance is water.

[0034] Among them, cetyl ethyl hexanoate, isononyl isononanoate, and isohexadecane are oils, polyoxyethylene sorbitol tetraisostearate, and PEG-20 glycerol triisostearate are oils. Phase emulsifier, the above oil and oil phase emulsifiers are all oil phase components;

[0035] PEG-6 caprylic acid / capric glycerides are water phase emulsifiers, 1.3 propylene glycol is a humectant, EDTA-2NA is a chelating agent, citric acid and dipotassium glycyrrhizinate are used as pH regulators, 1,2-hexanediol, octyl Hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com