Suction-blowing type seed cotton conveying apparatus

A conveying device and seed cotton technology, which is applied in the directions of picking machines, agricultural machinery and implements, and applications, and can solve the problem of no seed cotton conveying device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

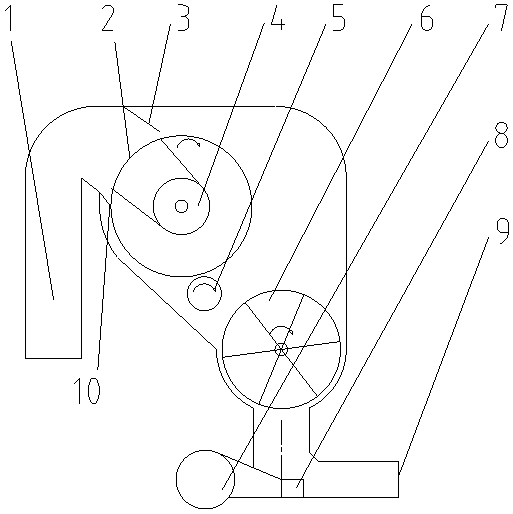

[0017] The suction-blowing type seed cotton conveying device of the present embodiment, as figure 1 , including: seed cotton inlet channel 1, isolation cover 2, blower fan, brushing roller 5, air closing valve 6, jet nozzle 8, seed cotton outlet channel 9 and housing; isolation cover 2 is a hollow cylinder, and its side is formed by a grid Composition; the isolation cover 2 is hinged in the shell close to the seed cotton inlet channel 1, and the isolation cover 2 can rotate around its own axis; the air inlet 4 of the fan is arranged in the isolation cover 2, and the isolation cover 2 is also arranged with a direction toward the seed cotton inlet channel. 1 air duct; the air inlet 4 communicates with the seed cotton inlet passage 1 through the air duct; the air duct defines the axially divided part of the side of the isolation cover 2 and can receive the airflow flowing into the air inlet 4 from the seed cotton inlet passage 1; The brushing roller 5 is arranged under the isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com