A local magnetization device

A magnetization device and local technology, applied in the direction of measuring device, material magnetic variable, material analysis through electromagnetic means, etc., can solve the problems of short support base plate length, small size range of workpiece, difficult to control probe gap and axis, etc., to achieve increase Probe fine-tuning structure, convenient on-site installation, convenient on-site debugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

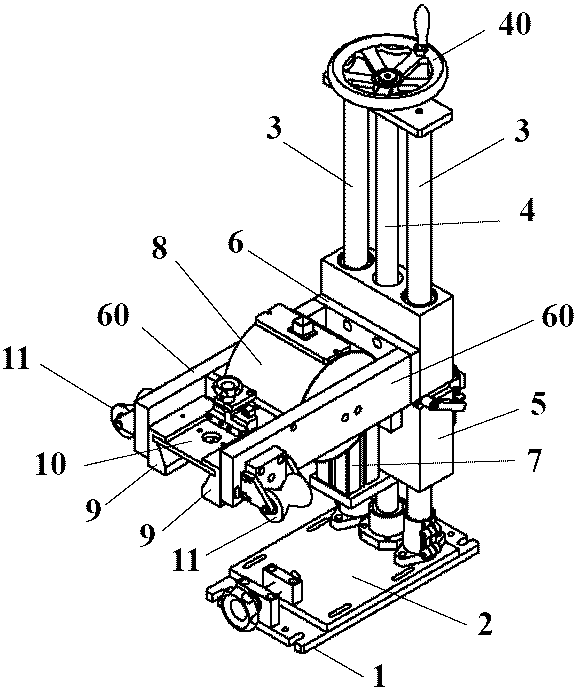

[0026] Example 1, such as figure 1 , 2 , 3, and 4, a local magnetization device includes a base 1, a lateral adjustment plate 2, a pillar 3, a threaded transmission shaft 4, a lifting bracket 5, a yoke 6, a cylinder 7, a magnetization coil 8, a magnetic shoe 9, and a probe Fixed adjusting frame 10, guide wheel 11 are characterized in that:

[0027] The horizontal adjustment plate 2 is fixed on the upper surface of the base 1, and the lateral adjustment movement of the horizontal adjustment plate 2 on the upper surface of the base 1 is controlled by adjusting the adjustment mechanism on the horizontal adjustment plate 2;

[0028] There are two pillars 3, which are vertically fixed on the upper surface of the horizontal adjustment plate 2 side by side;

[0029] The threaded transmission shaft 4 is vertically fixed on the upper surface of the lateral adjustment plate 2 between the two pillars 3, the top of the threaded transmission shaft 4 is fixed with a hand wheel 40, and the...

Embodiment 2

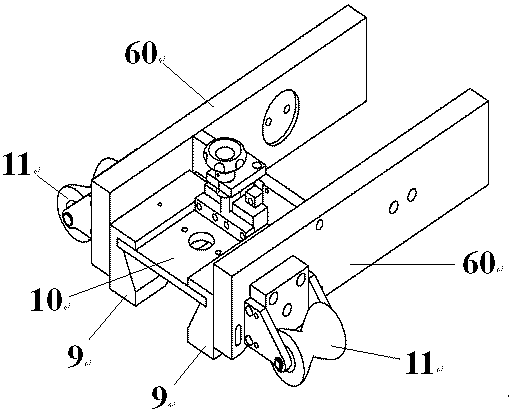

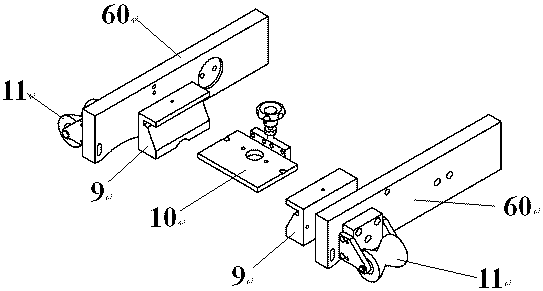

[0036] Example 2, such as Figure 5 , 6 As shown, further, the cylinder 7 is fixed on the lifting bracket 5, the piston rod 70 of the cylinder 7 is downward, and the moving direction of the piston rod 70 of the cylinder 7 is parallel to the pillar 3; the yoke 6 is fixed on the piston below the cylinder 7 The top 71 of the rod 70, the pillar 3 passes through the yoke 6, the two arms 60 of the yoke 6 are perpendicular to the pillar 3, the cylinder 7 controls the yoke 6 to move back and forth along the pillar 3 through the piston rod 70, and the piston rod 70 of the cylinder 7 moves downward When the yoke 6 is fixed below it, the cylinder 7 controls the reciprocating movement range of the yoke 6 to be small, which can be used to detect workpieces with small diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com