Integrated type six degrees of freedom precision positioning platform

A precision positioning and degree of freedom technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of no large rotating and swinging platform, limited freedom of movement, complex structure, etc., to meet processing and operation requirements , Eliminate inter-axis displacement coupling, high displacement resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

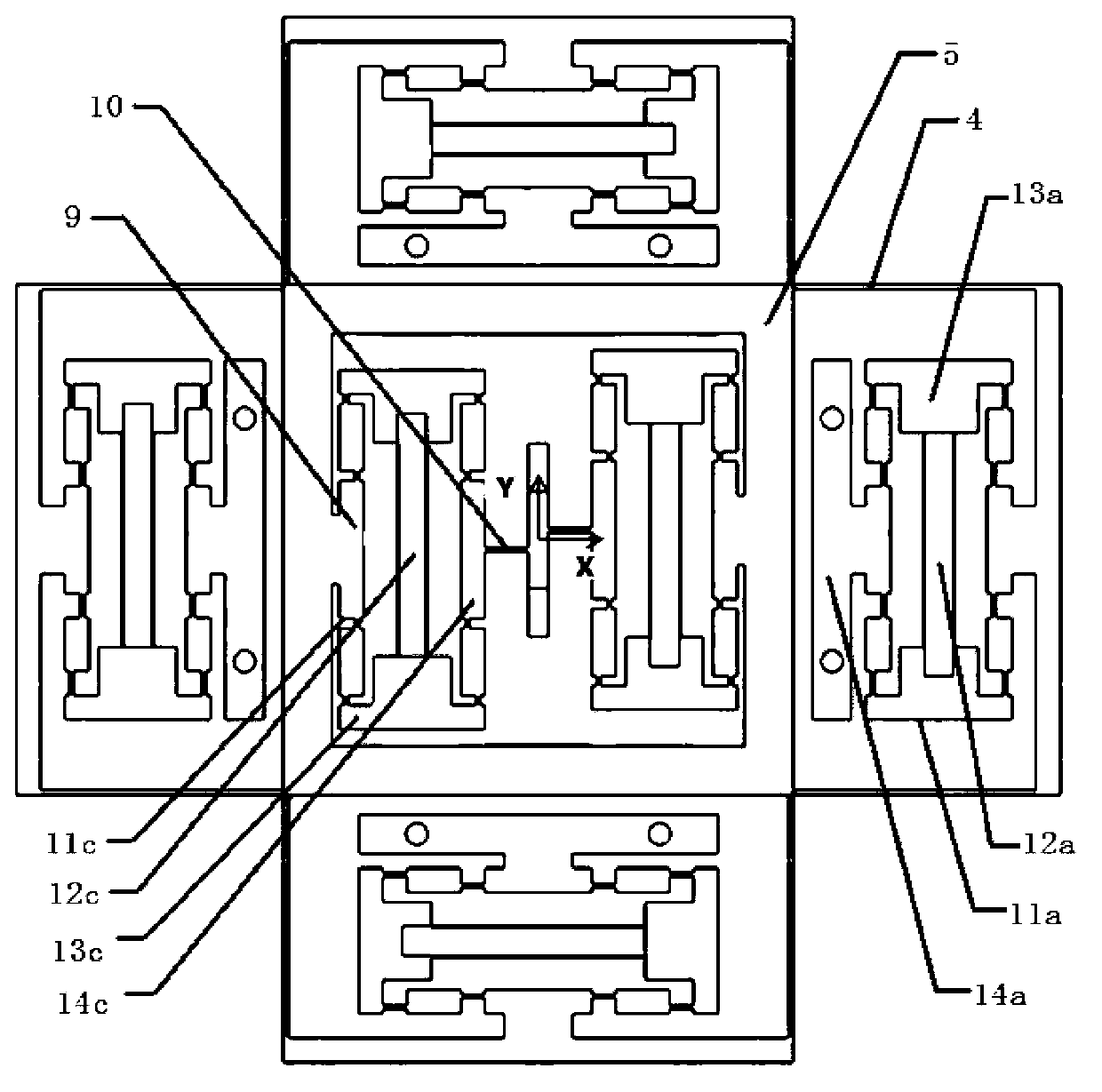

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 The top view of the upper platform is removed for the present invention, as shown in the figure: the integrated six-degree-of-freedom precision positioning platform of this embodiment includes a base 1, a lower platform assembly, an intermediate platform assembly and an upper platform assembly, and the upper surface of the base 1 One point is the origin, and the plane is used as the XY plane to establish a space Cartesian coordinate system X-Y-Z; for example figure 1 As shown, the base 1 is a square plate, the space Cartesian coordinate system X-Y-Z takes the midpoint of the upper surface of the base 1 as the origin, and the X-axis and Y-axis are parallel to any group of borders of the base 1. The base 1 and the lower platform assembly , middle platform components and upper platform components are connected sequentially from bottom to top;

[0019] The lower platform assembly includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com