Two-stage micro-displacement amplification mechanism

An amplifying mechanism and micro-displacement technology, which is applied to device parts, piezoelectric devices/electrostrictive devices, etc., can solve the problems of difficulty in obtaining amplified output displacement, difficulty in accurately realizing the target action, and limited displacement magnification, etc. External connection, compact structure, and the effect of improving displacement magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

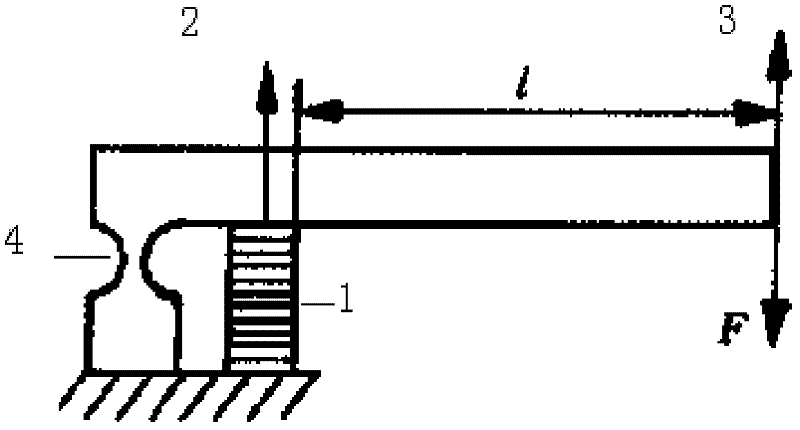

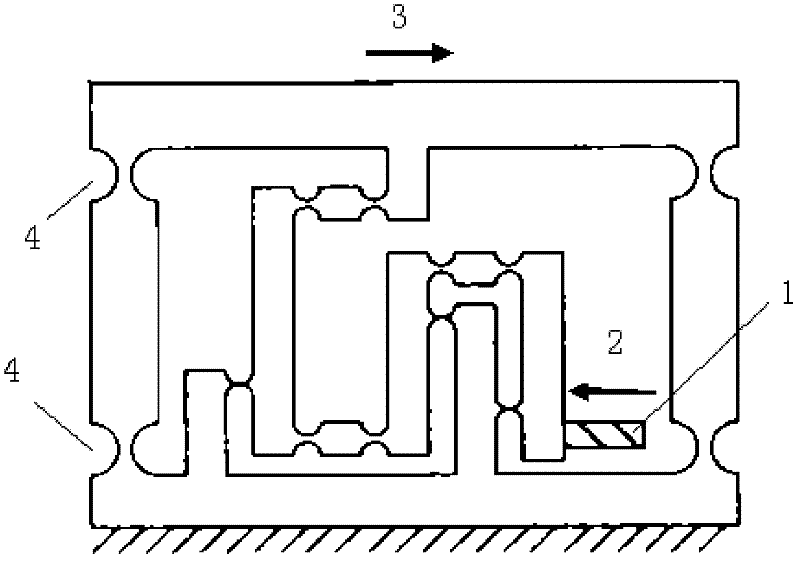

[0031] Embodiment 1, two-stage micro-displacement amplification mechanism, refer to Figure 4~Figure 7 : There are two triangle displacement scalers, which are respectively the first-level triangle displacement scaler 6-A and the second-level triangle displacement scaler 6-B; each triangle displacement scaler consists of four hypotenuses 6-1, 6- 2, 6-3, 6-4 are formed; the input end 2 of the first-stage triangular displacement scaler 6-A is connected with the drive element 1; the output end 3 of the first-stage triangular displacement scaler 6-A is connected to the second-stage triangle The input 2 of the displacement scaler 6-B is connected. The connection between the four hypotenuses 6-1, 6-2, 6-3, 6-4 of the triangle displacement scaler and the displacement input terminal 2, and the four hypotenuses 6-1, 6-2, 6-3, 6- 4 and the displacement output end 3 are all provided with flexible hinges 4; the displacement input end of each triangular displacement scaler is provided wit...

Embodiment 2

[0032] Example 2, in Figure 8 In the embodiment of the invention, the driving element 1 and the single-stage micro-displacement amplification mechanism 6 can be glued together directly. When in use, when the driving element 1 outputs displacement, through the amplification effect of the single-stage micro-displacement amplifying mechanism 6, an amplified displacement output can be obtained at the output end of the single-stage micro-displacement amplifying mechanism 6.

Embodiment 3

[0033] Example 3, in Figure 9 , Figure 10 In the embodiment of the present invention, the drive element 1 is first connected to the single-stage micro-displacement amplification mechanism 6-A, and then the single-stage micro-displacement amplification mechanism 6-A is connected to the single-stage micro-displacement amplification mechanism 6-B, and the two are orthogonal Join placement. The method of use is the same as that of the single-stage micro-displacement amplification mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com