Bearing type hinge

A technology of hinges and bearings, applied to hinges with pins, door/window accessories, hinges, etc., can solve the problems of low reliability, complex structure, high reliability, etc., and achieve convenient connection, simple structure, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

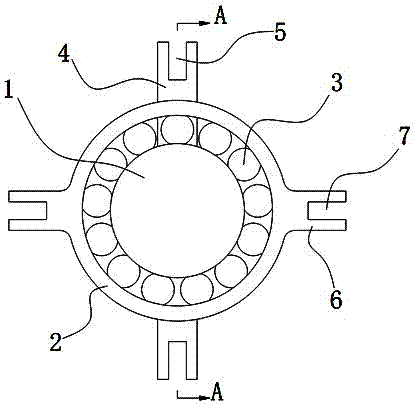

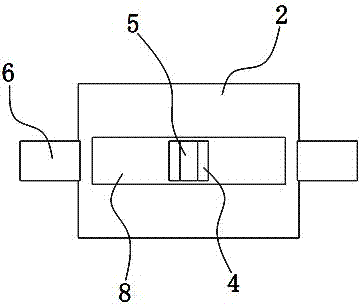

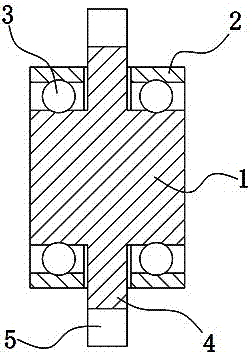

[0020] like Figure 1 to Figure 3 As shown, the bearing hinge includes a mandrel 1, a sleeve 2 and a ball 3, the mandrel 1 is coaxially set in the sleeve 2, and a plurality of balls 3 are installed between the mandrel 1 and the sleeve 2, and the sleeve 2. It can rotate coaxially with respect to the mandrel 1. On the side wall of the mandrel 1, a first pendulum plate 4 is arranged symmetrically. On the side wall of the sleeve 2, a pendulum groove 8 is symmetrically opened along its circumference. The plate 4 protrudes from the swing groove 8 , and a second swing plate 6 is symmetrically arranged on the outer wall of the sleeve 2 .

[0021] Further, a first swing plate opening 5 is provided at the end of the first swing plate 4, and the first swing plate opening 5 is a U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com