Roller and method for controlling local glue amount of packaging box surface paper

A packaging box and roller technology, applied in packaging, transportation and packaging, box making operations, etc., can solve problems such as weak adhesion and easy opening of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

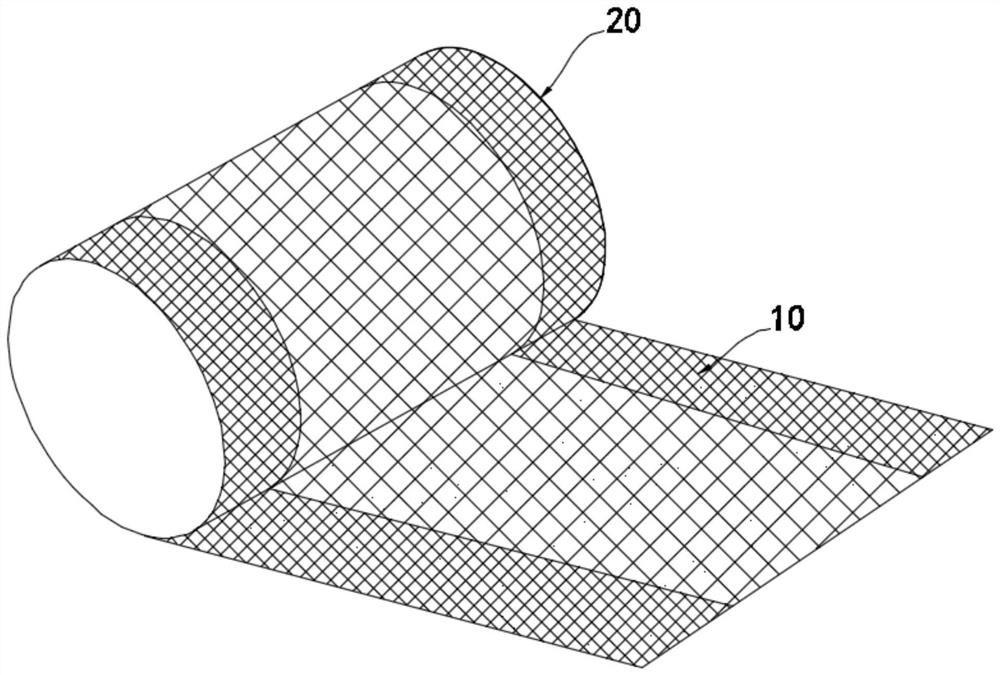

[0027] Please combine figure 1 , figure 2 and image 3 ,

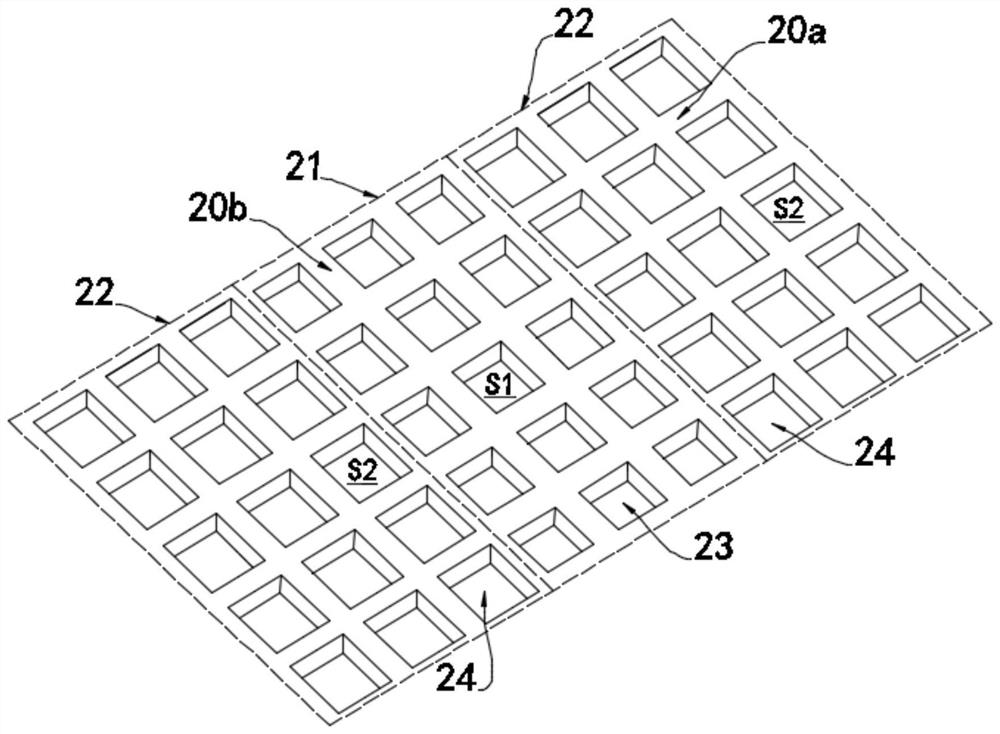

[0028] A roller 20 is formed on the roller with several mesh walls and several mesh holes, and the mesh walls are extended along at least two directions to cross to form at least two different mesh holes. When the roller is passing the glue, the roller is in contact with the glue and rotates. The surface of the roller is dipped in a large amount of glue, and the glue is scraped along the peripheral surface of the roller through the scraper so that the glue on the surface of the roller is only left in the mesh. All the glue outside the hole is scraped off; the facial paper 10 rolls along the surface of the roller, and the glue will be transferred from the mesh to the facial paper 10 . By setting different meshes on the roller, a non-continuous non-uniform over-glue will be formed on the face paper 10 .

[0029] Such as figure 2 , the direction of net wall one 20a and net wall two 20b is perpendicular to each othe...

Embodiment 2

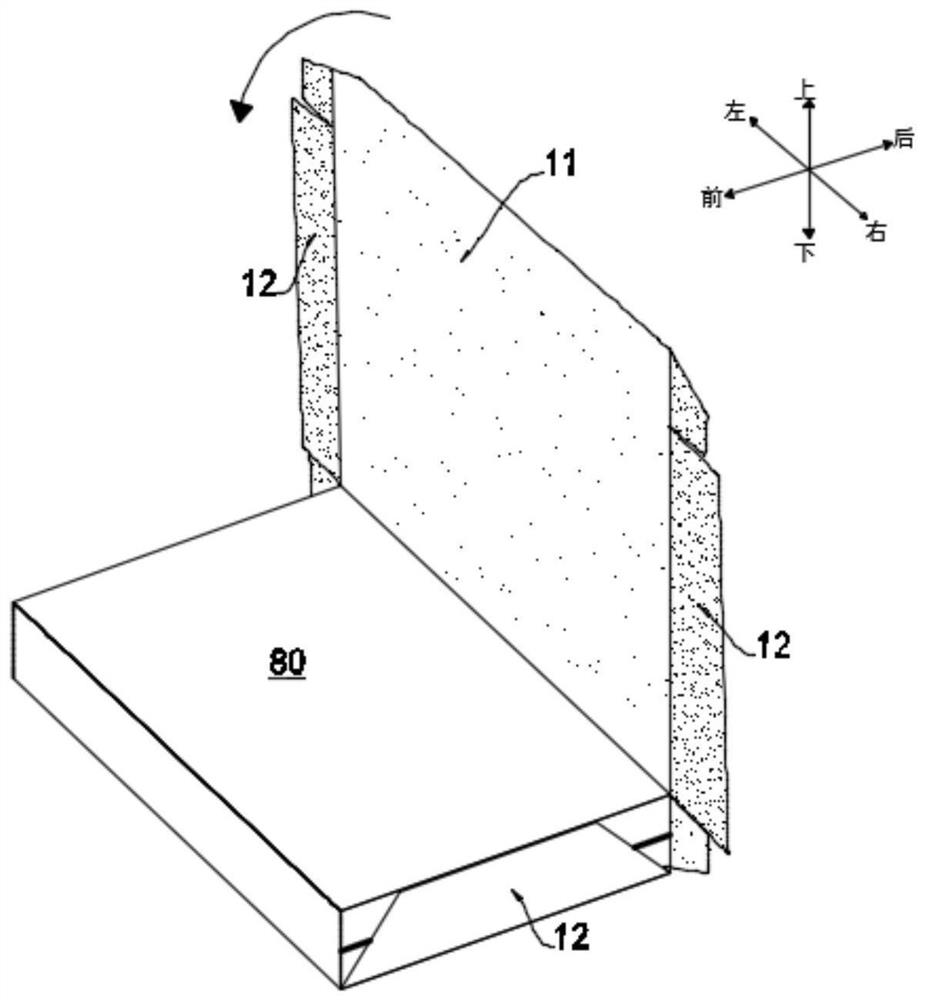

[0034] to borrow figure 1 , image 3 , when the opening of the mesh is the same, the depth of the hole is different; in this case, the mesh is also divided into at least two types, deep hole 34 and shallow hole 33, and on the roller surface, it is shown as deep hole area 32 and shallow hole District 31. The depth two D2 of deep hole 34 is greater than the depth one D1 of shallow hole 33, under the same situation of orifice, then the capacity of deep hole 34 is also greater than the capacity of shallow hole 33, that is to say the glue capacity stored in deep hole 34 is greater than Glue volume in shallow hole 33.

[0035] combine Figure 4 , further, two deep hole areas 32 and one shallow hole area 31 are set on the roller surface. Using this roller to glue the face paper 10 will still realize that the glue density of the side surface 12 is greater than the glue density of the middle surface 11.

[0036] In this case, the width of the net wall one 20a can be the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com