Small-diameter spiral heat exchange tube magnetic flux leakage internal detection device and series-parallel detection method

A technology of spiral heat exchange tubes and detection devices, applied in the direction of material magnetic variables, etc., can solve problems such as fire accidents, safety detection difficulties, and affecting the use of heat exchange equipment, and achieve easy disassembly and replacement, low detection efficiency, and small bending stiffness Effect

Active Publication Date: 2019-07-05

NORTHEAST GASOLINEEUM UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The safety status of the spiral heat exchange tube has a crucial impact on production and operation. Once it leaks, it will cause material mixing, which will affect the normal production, and cause a fire accident if it is serious.

If the spiral heat exchange tube is corroded to a certain extent, it will affect the use of the heat exchange equipment, and it needs to be repaired and replaced. If the corrosion defect cannot be found in time, the heat exchange tube will run with hidden dangers, which will affect the safety and stability of the device. , long-term operation

However, due to the structural shape of the spiral heat exchange tube, it is difficult to implement its safety inspection

[0006] At present, the defect detection technology for straight heat exchange tubes and large-diameter spiral heat exchange tubes has become increasingly mature, but there is no relevant technology for the safety detection of small-diameter spiral heat exchange tubes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0052] Embodiment: Below in conjunction with accompanying drawing, the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

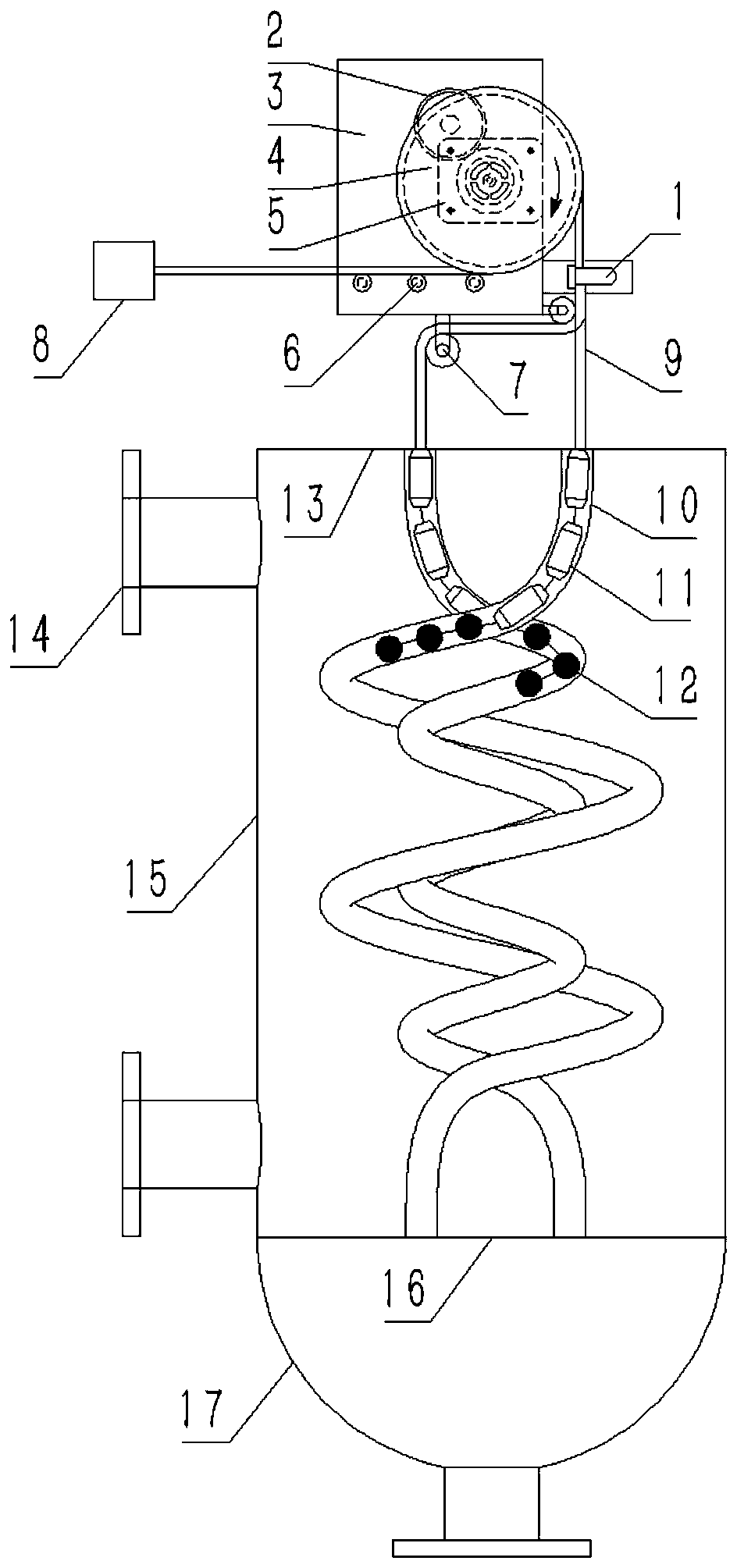

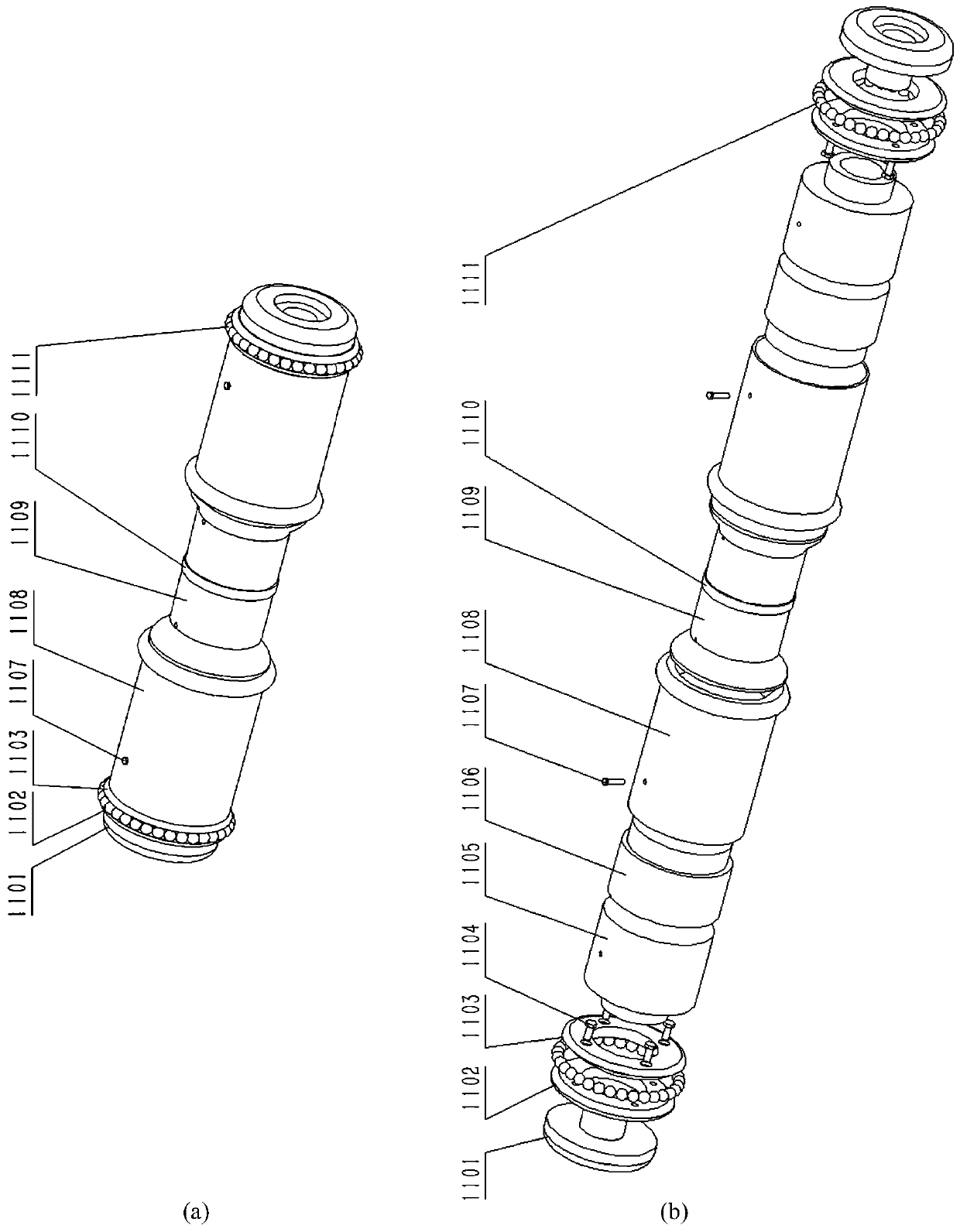

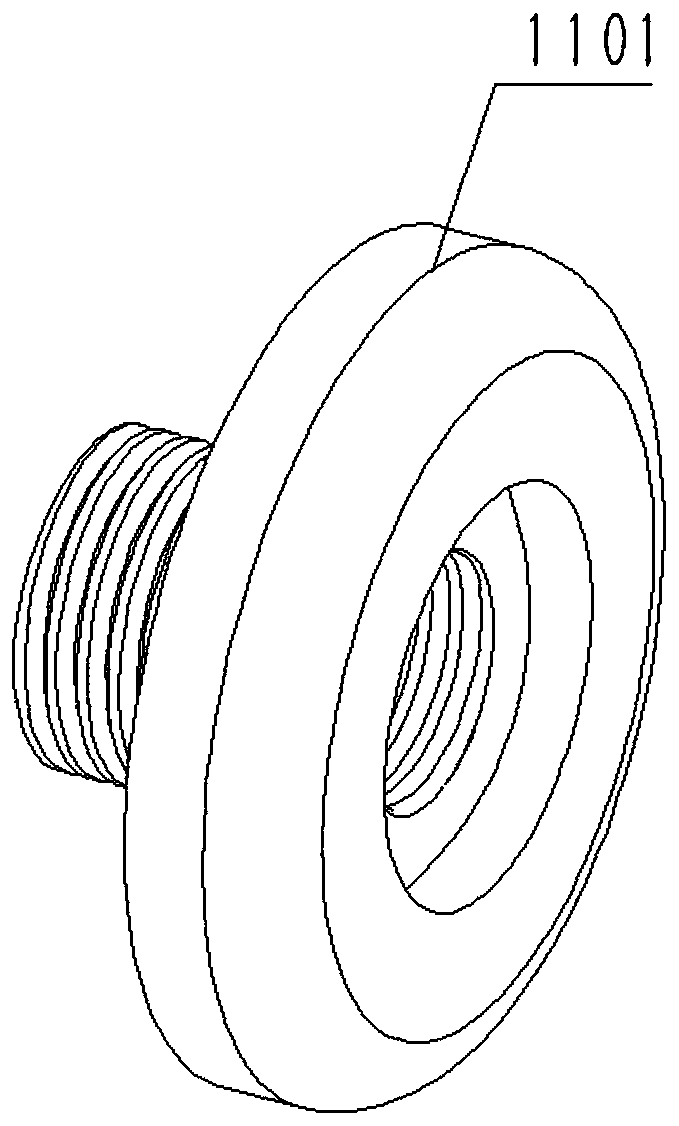

The invention discloses an internal detection device and a series-parallel detection method for magnetic flux leakage of a small-diameter spiral heat exchange tube, and relates to an internal detection technology of the magnetic flux leakage of a spiral heat exchange tube. In order to realize the internal detection of magnetic flux leakage of small diameter spiral heat exchange tubes. The device includes a probe drive mechanism and at least one detection probe; the probe drive mechanism drives the detection probe to move in the heat exchanger tube; the detection probe includes an intermediate connecting body, and magnetized bodies and steel balls that are coaxially arranged at both ends of the intermediate connecting body in turn. Support body, end connecting body; each magnetized body includes an armature, a magnet and a steel tube cylinder arranged on the peripheral axis; choose to connect multiple detection probes in series in a single tube, and then connect the previous series detection in multiple tubes. The probes are used in parallel to detect multiple pipes at the same time, which greatly improves the detection efficiency and saves time and manpower.

Description

technical field [0001] The invention relates to a magnetic flux leakage internal detection device and a detection method of a spiral heat exchange tube, in particular to an internal detection device and a detection method for a series-parallel connection of a small-diameter spiral heat exchange tube magnetic flux leakage. [0002] Background of the invention [0003] In today's world, energy is one of the most important issues faced by human beings. The development, conversion and utilization of energy is an important issue for all countries. Heat exchangers are widely used in chemical industry, metallurgy, transportation, aviation and aerospace and other departments, and are one of the indispensable equipment in the process of energy utilization. About 40% of the equipment in oil refining and chemical plants are heat exchangers, accounting for 30% to 45% of the total investment. The heat exchanger is not only expensive to invest, but also the quality of the heat exchanger i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N27/83

CPCG01N27/83

Inventor 崔巍张强孙凯王珂宋日悬张煜杭

Owner NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com