A method for rapid cooling of high-temperature flue gas

A high-temperature flue gas and flue gas technology, which is applied in the field of high-temperature flue gas cooling, can solve the problems of acetylene quality impact, energy waste, and aggravate the cost of chemical enterprises, so as to achieve the effect of reducing cost and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

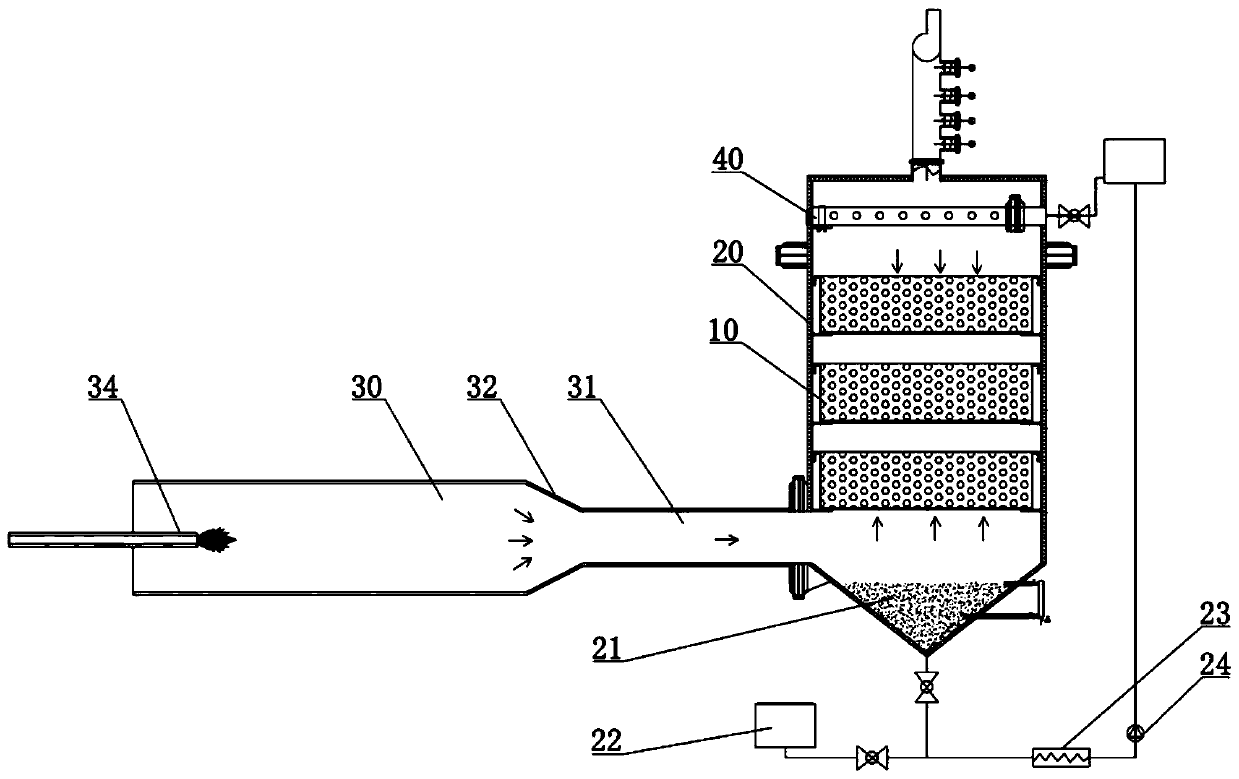

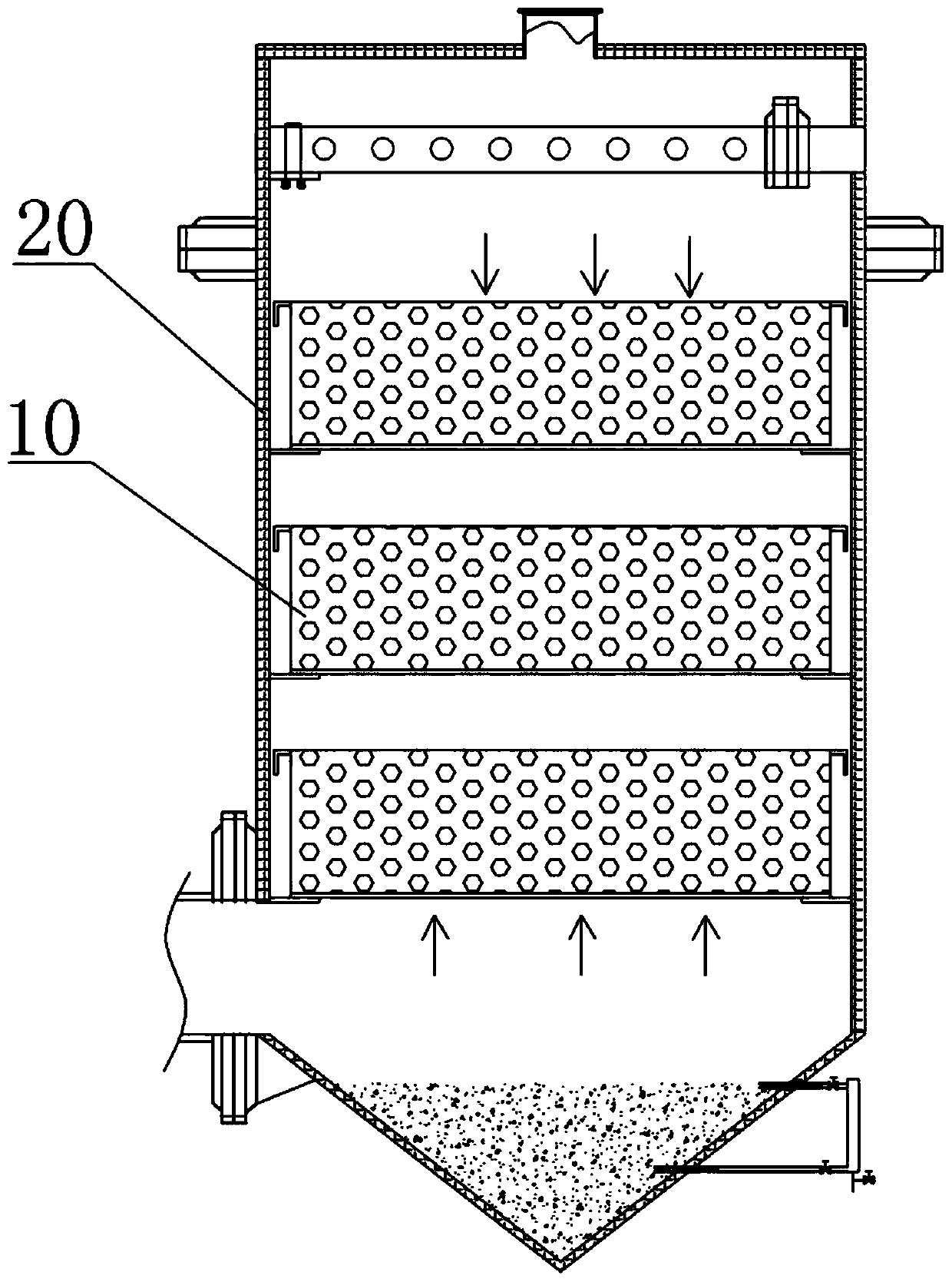

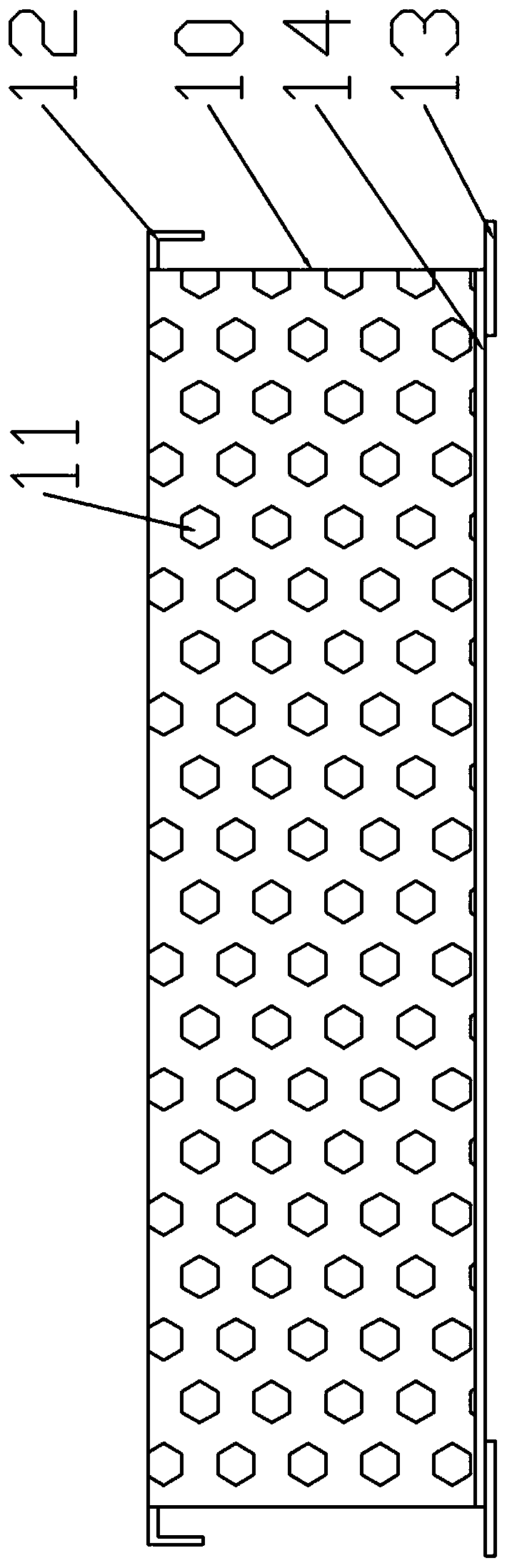

[0034] as attached figure 1 A high-temperature flue gas quenching device is shown, which includes a heat exchange furnace 20, and also includes a flue gas input mechanism and a quenching mechanism located in the heat exchange furnace. Road, the quenching mechanism includes a dispersing plate 40 arranged in the heat exchange furnace from top to bottom, a packing structure, a liquid accumulation pool 21, and a circulation unit that realizes the circulation of the quenched liquid. The circulation unit includes a heat exchanger 23 communicated with the liquid accumulation pool, The electromagnetic pump 24 that drives the flow of the quenching liquid, the liquid storage tank 1 22 connected to the effusion pool, and the liquid storage tank 2 connected to the dispersing plate and the electromagnetic pump, the setting of the liquid storage tank 1 and the liquid storage tank 2 ensures the supply of the quenching liquid , storage, which is beneficial to the high-efficiency circulation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com