Waste liquid combustion treatment system

A treatment system and waste liquid technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve problems such as deterioration of temperature conditions, waste of secondary energy, fire hazards, etc., to eliminate safety hazards, good absorption effect, and low overall cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

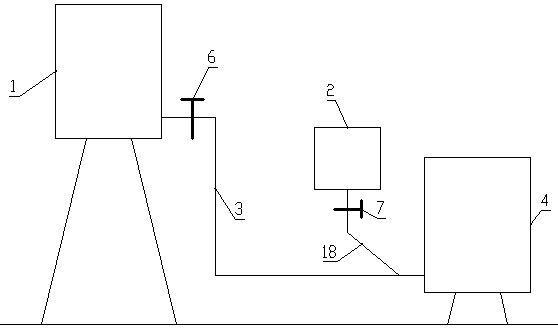

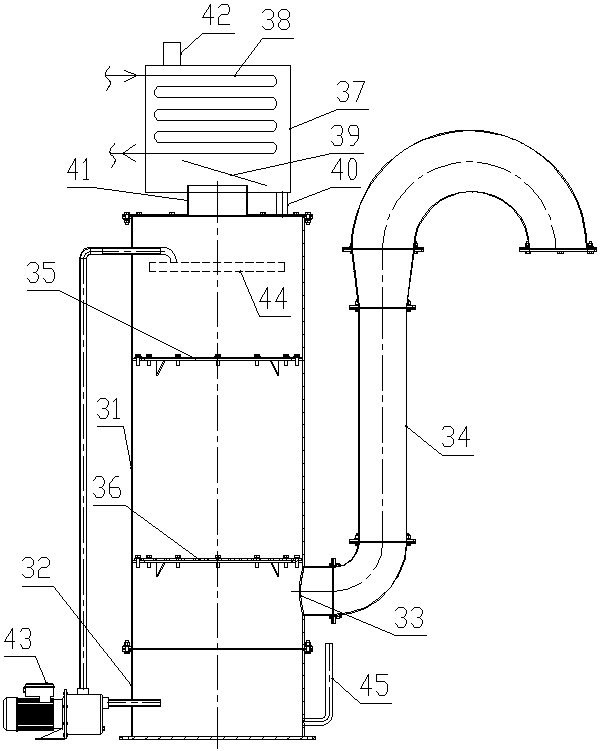

[0050] Such as Figure 1 to Figure 11 As shown, the waste liquid combustion treatment system of the present invention includes a waste liquid combustion device, a heat recovery heat exchanger and a tail gas treatment device.

[0051] Such as Figure 1 to Figure 6 As shown, the waste liquid combustion device includes a collection tank 1 for containing waste liquid fuel and a high-pressure gas source 2 for providing compressed air. The collection tank 1 is connected to a waste liquid combustion furnace through a waste liquid pipe 3; the flow of waste liquid The direction is the downstream direction;

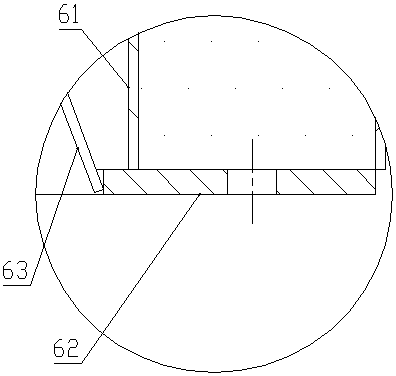

[0052] The waste liquid combustion furnace includes a furnace body 4 made of steel. The horizontal section of the furnace body 4 is circular. The inner wall of the furnace body 4 is provided with a refractory mud layer 5 so as to avoid direct heating of the furnace body 4 by high flame temperature and avoid excessive temperature of the furnace body 4. ; The lower end of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com