Siphon oil discharging device and method for oil tank truck

A technology of oil tanker and siphon, applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc. It can solve the problems of long working time, oil leakage, complicated process of disassembling and assembling pipelines, etc., and achieves convenience for personnel Effects of operation and speeding up the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

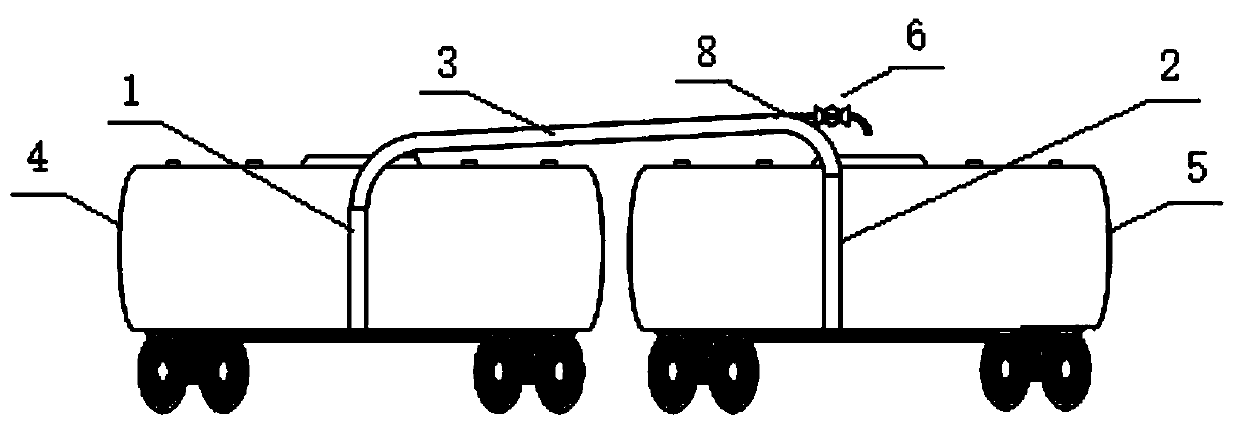

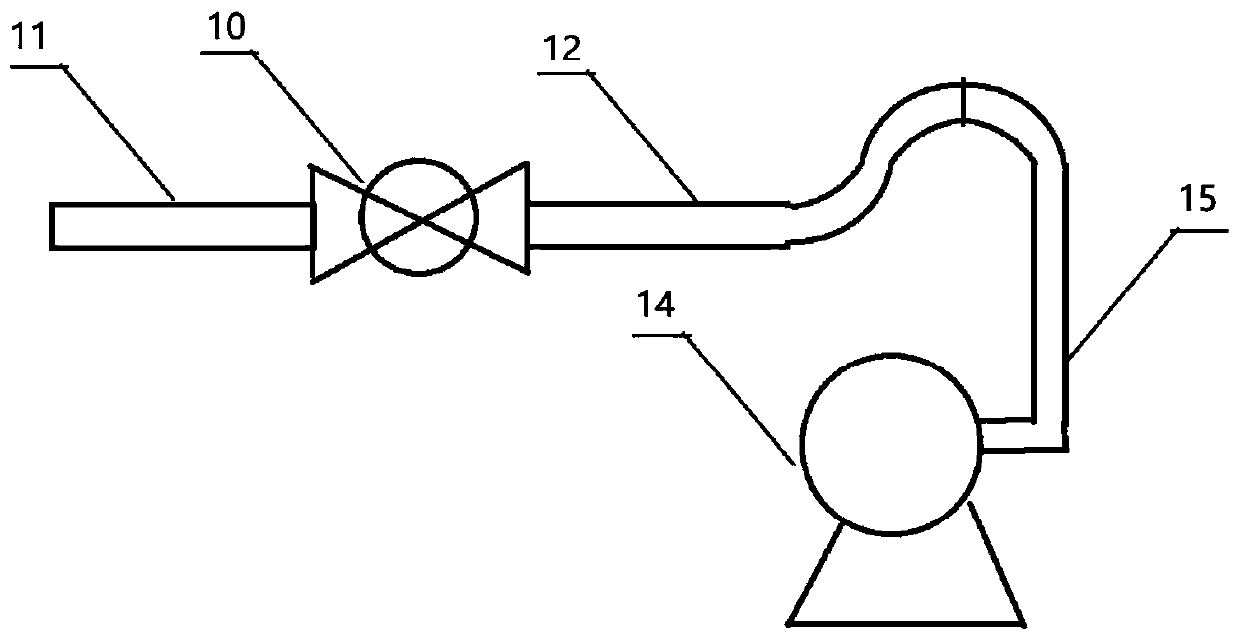

[0024] Such as Figure 1-2 As shown, the tank car siphon oil unloading device of the present invention generally includes a main oil unloading joint 2, one end of the main unloading oil joint 2 extends into the main unloading tank car 4; One end of the oil connection pipe extends into the secondary oil unloading tank car 5; a connecting pipe 3, the two ends of the connecting pipe 3 are respectively sealed and connected with the other end of the main oil unloading pipe 2 and the other end of the secondary oil unloading pipe 1 through the top quick connector , the connecting pipe 3 is provided with an exhaust pipe interface 8 near the end of the main unloading tank car 4; an exhaust assembly 6, the exhaust assembly 6 is connected to the exhaust pipe interface 8, and is used for the inside of the siphon oil unloading device discharge of the initial gas.

[0025] In order to obtain a better exhaust and oil introduction effect, in one embodiment of the present invention, the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com