Vertical joint connection joint of steel tube concrete prefabricated shear wallboards and assembling method thereof

A technology of steel pipe concrete and prefabricated wall panels, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult connection of steel bars, difficult quality assurance, and difficult construction, so as to avoid continuous collapse, simple assembly process, and overall structure Good performance in sex and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

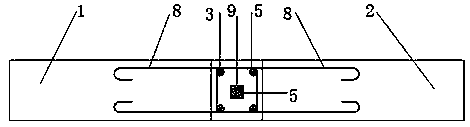

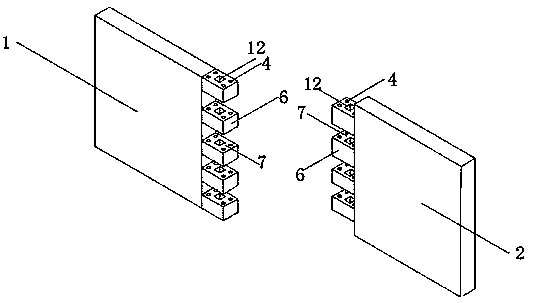

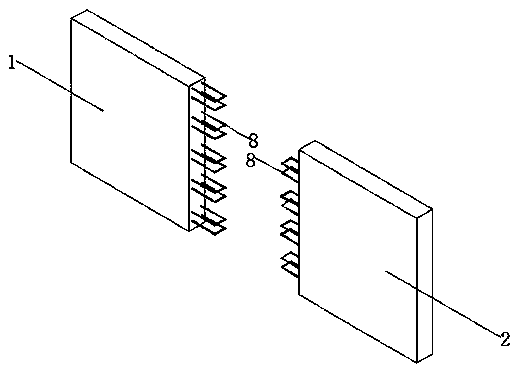

[0024] like Figure 1-4 As shown, the vertical joint connection nodes and assembly methods of concrete-filled steel pipe prefabricated shear wall panels include left prefabricated wall panel 1, right prefabricated wall panel 2, ribs 3, rib holes 4, grouting material 5, protrusions 6, and grooves 7. Pre-buried anchor bars 8, square steel pipes 9 and square steel pipe holes 12; the prefabricated wall panels are provided with two pieces, including a left prefabricated wall panel 1 and a right prefabricated wall panel 2. Set the corresponding quantity and shape according to different needs. The connection end of the prefabricated wall panel is provided with a connection groove 7 and a protrusion 6 along the vertical direction. The protrusion 6 is equipped with a pre-embedded anchor bar 8, and the pre-embedded anchor bar 8 is U-shaped. , one end holds and wraps the steel bars in the prefabricated wall panels, the other end wraps the inserted ribs 3 and the square steel pipes 9, the...

Embodiment 2

[0027] like Figure 5 As shown, the vertical joint connection node and assembly method of the prefabricated steel pipe concrete shear wall panel, including the left prefabricated wall panel 1, inserting bar 3, inserting bar hole 4, grouting material 5, protrusion 6, groove 7, and pre-embedded anchor bars 8. Square steel pipe 9, rear prefabricated wallboard 11, square steel pipe hole 12; said prefabricated wallboard is provided with two pieces, including prefabricated wallboard left 1 and rear prefabricated wallboard 11, the shape of the composition is L-shaped, can be Set the corresponding quantity and shape according to different needs. The connection end of the prefabricated wall panel is provided with a connection groove 7 and a protrusion 6 along the vertical direction. The protrusion 6 is equipped with a pre-embedded anchor bar 8, and the pre-embedded anchor bar 8 is U-shaped. , one end holds and wraps the steel bars in the prefabricated wall panels, the other end wraps t...

Embodiment 3

[0029] like Figure 6 As shown, the vertical joint connection nodes and assembly methods of concrete-filled steel pipe prefabricated shear wall panels include left prefabricated wall panel 1, right prefabricated wall panel 2, ribs 3, rib holes 4, grouting material 5, protrusions 6, and grooves 7. Embedded anchor bars 8, square steel pipes 9, rear prefabricated wallboards 11, and square steel pipe holes 12; the prefabricated wallboards are provided with three pieces, including left prefabricated wallboard 1, right prefabricated wallboard 2 and rear prefabricated wallboard 11. The shape of the composition is T-shaped, and the corresponding quantity and shape can be set according to different needs. The connection end of the prefabricated wall panel is vertically provided with a connection groove 7 and a protrusion 6, and the protrusion 6 is equipped with embedded anchors Reinforcement 8, pre-embedded anchor reinforcement 8 is U-shaped, one end holds and wraps the reinforcement i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com