Replacement support and supporting structure of latticed shell

A technology of supporting structures and reticulated shells, which is applied to arched structures, dome structures, building components, etc., can solve the problems that bolt installation holes cannot correspond to each other, and require high precision for sliding construction, so as to reduce construction difficulty and The effect of reducing cost, shortening construction time, and reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

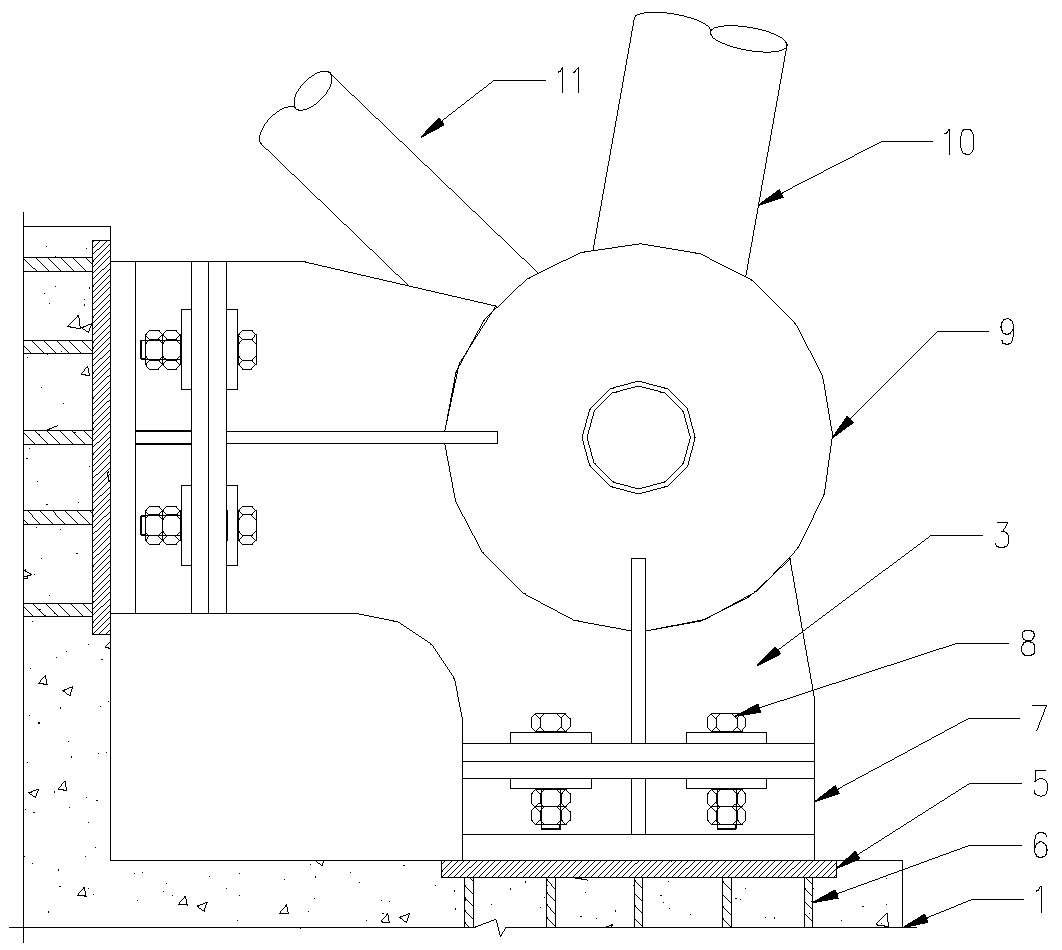

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0023] In this embodiment, in order to ensure the stability of the support structure, a lateral support structure and a vertical support structure are provided, but the two structures are the same. This embodiment only introduces the vertical support structure, and the lateral support structure No longer.

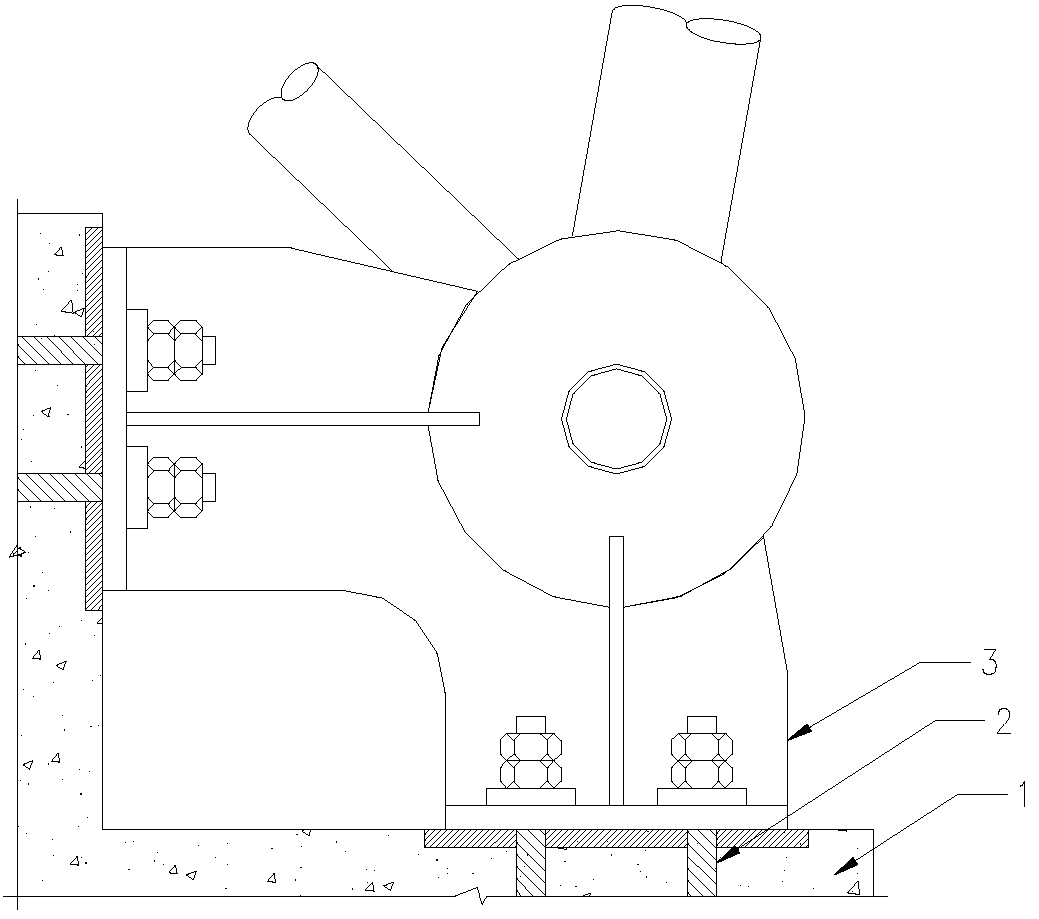

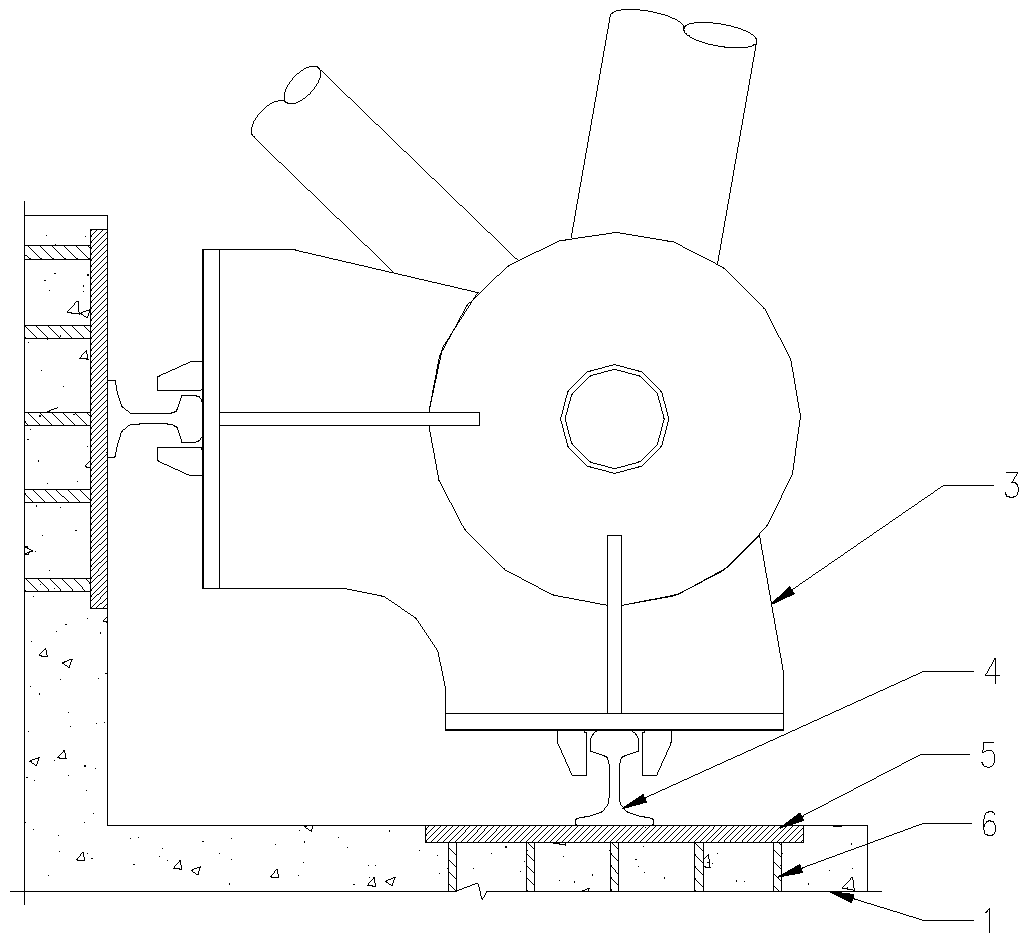

[0024] A support structure for a reticulated shell structure, comprising:

[0025] Replacement holder 7, see Figure 4~6 , which includes a top plate 701 and a bottom plate 702 arranged in parallel, and a rib plate 703 connected between the top plate 701 and the bottom plate 702, and a plurality of bolt holes 701a are opened on the top plate 701.

[0026] Support seat 3, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com