High-concentration sludge coal slurry, preparation method and application thereof

A high-concentration, sludge technology, applied in the manufacture of combustible gas, gasification process, petroleum industry, etc., can solve the problems of high energy consumption and low efficiency, and achieve low energy consumption, simple process flow and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

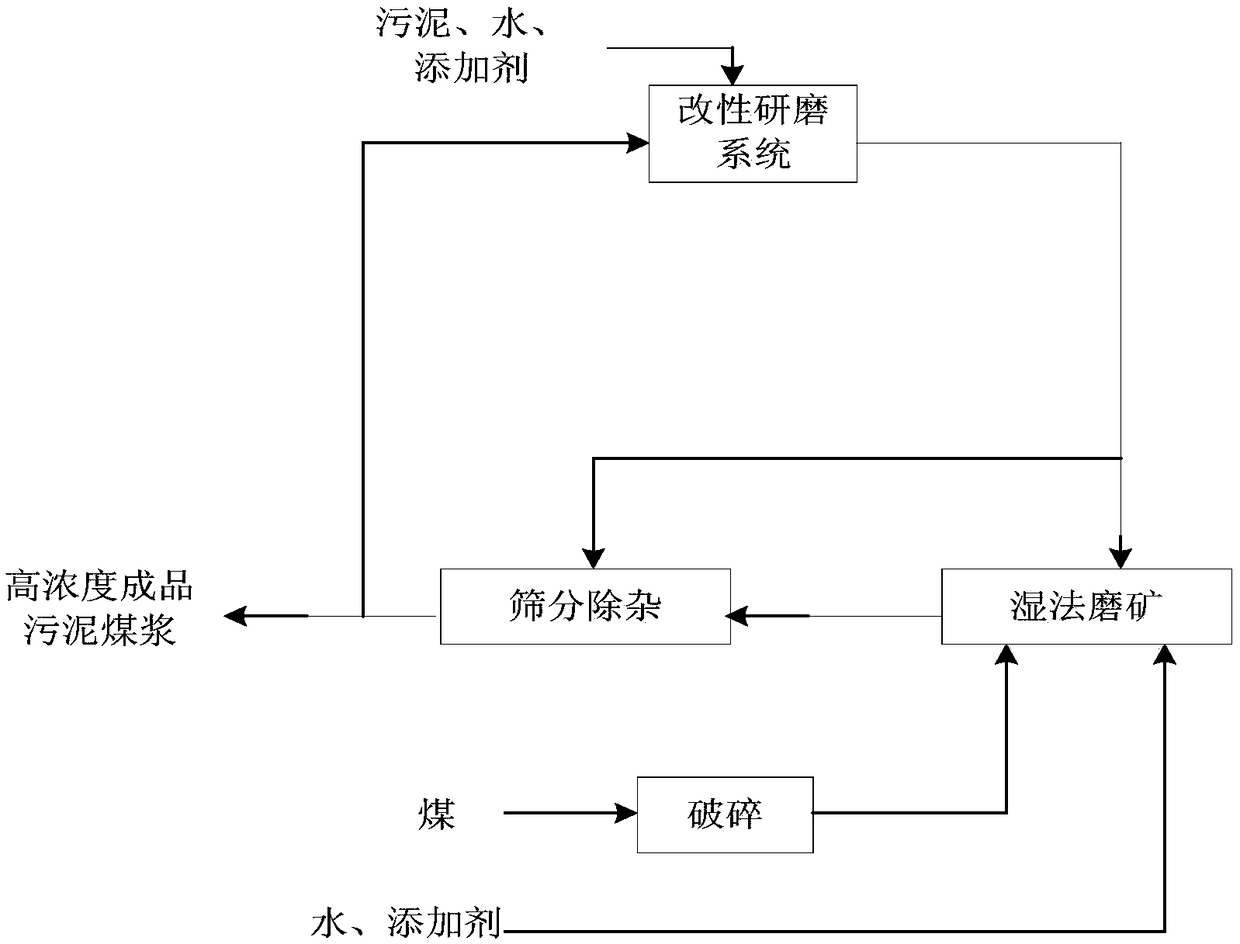

[0059] A kind of preparation method of high concentration sludge coal slurry, such as figure 1 shown, including the following steps:

[0060] (1) Carrying out shear refinement of the coal-water slurry, modified sludge, water and additives to obtain the first slurry;

[0061] (2) Carrying out shearing and thinning raw coal, water, additives and part of the first slurry to obtain the second slurry;

[0062] (3) Screening and removing impurities from the remaining first slurry and the second slurry to obtain the third slurry, part of the third slurry is returned to step (1) for replacing the coal water slurry in step (1), The remaining third slurry is the high concentration sludge coal slurry.

Embodiment 1

[0064] The raw coal used for the finished coal slurry and the crushed coal is low-rank coal in Yulin, Shaanxi, where the analytical water Mad is 2.32%, the total water Mt is 11.2%, the ash Aad is 9.89%, and the volatile Vdaf is 38.93%. The sludge used was produced by a sewage treatment plant of a coal chemical enterprise in Yulin, in which the analysis water Mad was 11.92%, the total water Mt was 81.63%, the ash content Ad was 52.72%, and the calorific value Qgr,d was 10.75MJ kg -1 .

[0065] Finished coal slurry is raw coal crushed to ≤6mm, mixed with water and additives at a ratio of 122:76:0.2 and then wet-grinded; the mass concentration of finished coal slurry is 61%, and its maximum particle size is ≤2.4mm. The fluidity index of slurry is 12cm. The fluidity index test of coal slurry refers to the test method of "fluidity of cement paste" in the industry standard of "GB / T8077-2012 Concrete Admixture Homogeneity Test Method" of cement. The stability of coal slurry is 2 Hou...

Embodiment 2

[0071] The raw coal used for the finished coal slurry and the crushed coal is low-rank coal in Yulin, Shaanxi, where the analytical water Mad is 2.32%, the total water Mt is 11.2%, the ash Aad is 9.89%, and the volatile Vdaf is 38.93%. The sludge used was produced by a sewage treatment plant of a coal chemical enterprise in Yulin, in which the analysis water Mad was 11.92%, the total water Mt was 81.63%, the ash content Ad was 52.72%, and the calorific value Qgr,d was 10.75MJ kg -1 .

[0072] Finished coal slurry is raw coal crushed to ≤6mm, mixed with water and additives in a ratio of 113.8:76:0.2 and then wet-grinded; the mass concentration of finished coal slurry is 60%, and its maximum particle size is ≤3.0mm. The fluidity index of slurry is 12cm. The fluidity index test of coal slurry refers to the test method of "fluidity of cement paste" in the industry standard of "GB / T8077-2012 Concrete Admixture Homogeneity Test Method" of cement. The stability of coal slurry is 2 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com