Waterborne high temperature resistant paint and preparation method thereof

A high-temperature-resistant, water-based technology, applied in the direction of anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of high-temperature resistance that needs to be further improved, poor thermal hardness and other physical properties, and serious environmental pollution, so as to alleviate VOC volatilization problems, excellent corrosion resistance, and the effect of improving the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] The preparation method of the present invention not only has the advantages of cleanliness, high efficiency, and low cost, but also has good stability of the prepared product, and is easy to operate, environmentally friendly, mild in preparation conditions, low in investment, low in energy consumption, and does not need to use complicated equipment systems, and is easy to It realizes industrialized mass production and has industrial applicability.

[0092] In a preferred embodiment, the preparation method of this water-based high temperature resistant paint comprises the following steps:

[0093] Take each component according to the mass parts;

[0094] First put the water-based modified silicone resin and water-based aluminum silver paste in the reaction kettle, and stir at a low speed; then add deionized water into the reaction kettle, and stir at a low speed; then add other additives into the reaction kettle, and stir and mix evenly. The water-based high temperature...

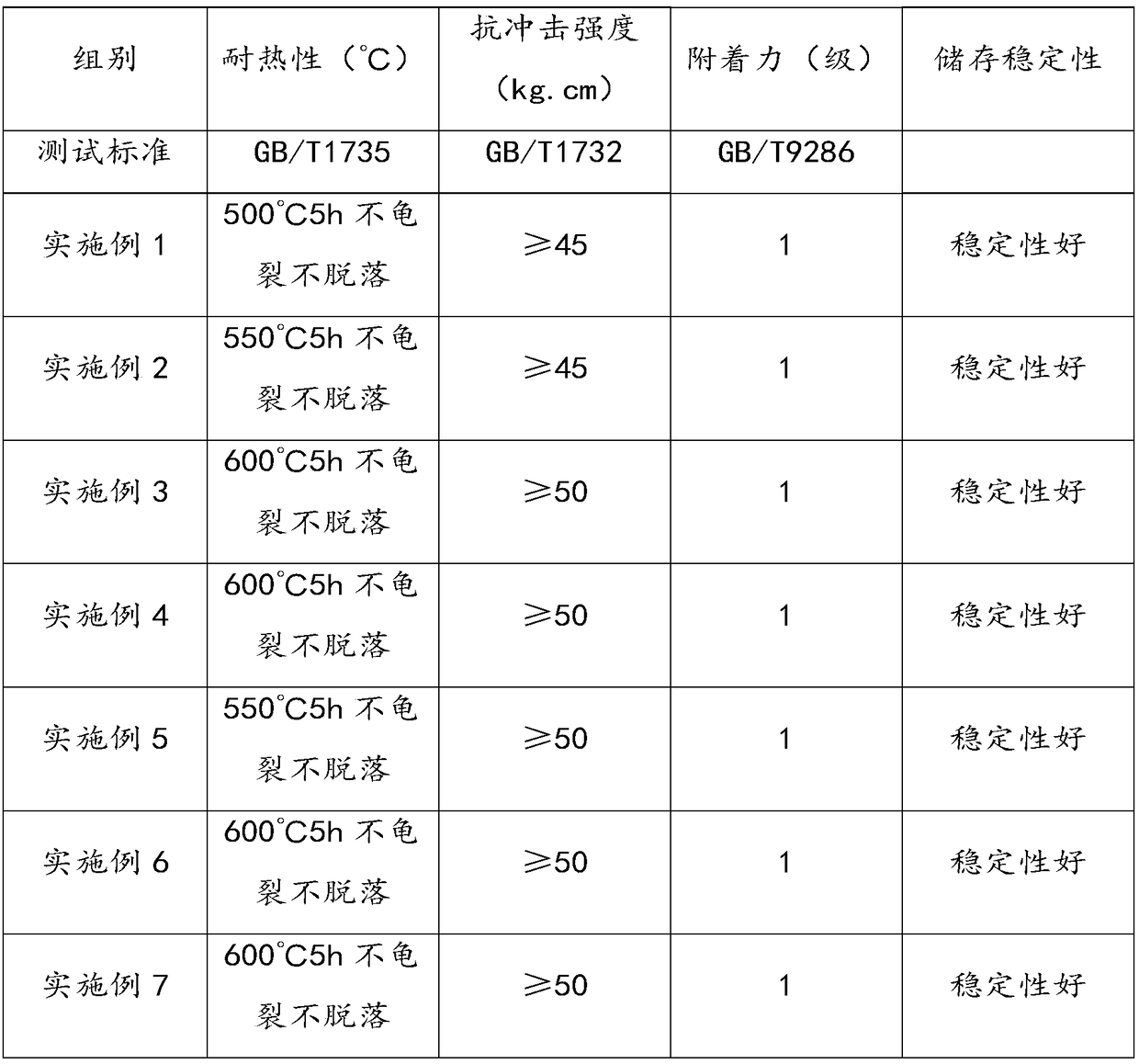

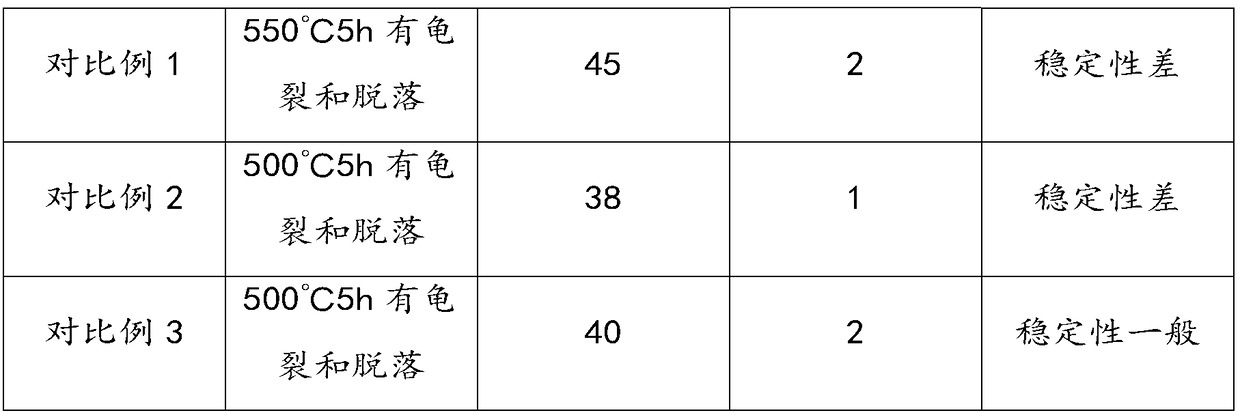

Embodiment 1

[0098] A water-based heat-resistant paint, comprising the following components in parts by mass:

[0099] 65 parts of water-based modified silicone resin, 16 parts of water-based aluminum silver paste, 6 parts of drier, 2 parts of leveling agent, 2 parts of dispersant and 9 parts of water.

Embodiment 2

[0101] A water-based heat-resistant paint, comprising the following components in parts by mass:

[0102] 56 parts of water-based modified silicone resin, 28 parts of water-based aluminum silver paste, 1 part of drier, 2 parts of leveling agent, 2 parts of dispersant and 11 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com