Rural wastewater treatment method based on recycling of landscape wetland

A technology for wastewater treatment and recycling, which is applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems that anaerobic fermentation is easy to produce sludge, affects the effect of wastewater treatment, and increases labor maintenance costs. , to achieve the effect of reducing floor space, reducing the use of chemical fertilizers, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

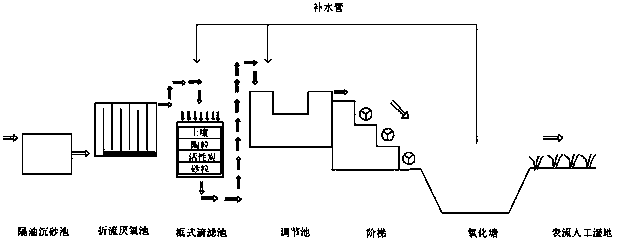

[0020] Treat rural wastewater in a mountainous area. The COD of the wastewater is 1424~1493mg / L. figure 1 The shown rural wastewater treatment facilities based on landscape wetland resources include an oil separation grit chamber, a baffle anaerobic pond, a frame trickling filter, a regulating pond, a ladder with a water wheel, an oxidation Pond and a surface flow artificial wetland, the baffle anaerobic pond is an anaerobic pond with three partitions alternately arranged on the top and bottom of the pool, and a baffle channel is formed in the baffle anaerobic pond, the distance between the partitions is 20cm, and the baffle The thickness of the activated carbon layer at the bottom of the anaerobic tank is 6cm; the frame-type trickling filter is equipped with a soil layer, a ceramsite layer, an activated carbon layer, and a sand layer from top to bottom. The thickness of the soil layer is 35cm. The thickness of the ceramsite layer is 25mm, the thickness of the ceramsite layer ...

Embodiment 2

[0025] To treat rural wastewater in a plain area, the average COD of the wastewater is 1857mg / L. figure 1 The shown rural wastewater treatment facilities based on landscape wetland resources include an oil separation grit chamber, a baffle anaerobic pond, a frame trickling filter, a regulating pond, a ladder with a water wheel, an oxidation Pond and a surface flow artificial wetland, the baffle anaerobic pond is an anaerobic pond with 5 partitions alternately arranged on the top and bottom of the pool, and a baffle channel is formed in the baffle anaerobic pond, the distance between the partitions is 15cm, and the baffle The thickness of the activated carbon layer at the bottom of the anaerobic tank is 10cm; the frame trickling filter is equipped with soil layer, ceramsite layer, activated carbon layer, and sand layer from top to bottom. The thickness of the soil layer is 40cm, and the average particle size of ceramsite in the ceramsite layer is The thickness of the ceramsite ...

Embodiment 3

[0029] Embodiment 3: Rural waste water in a certain plain area is treated, and the COD average value of this waste water is 1538mg / L, and the construction such as figure 1 The shown rural wastewater treatment facilities based on landscape wetland resources include an oil separation grit chamber, a baffle anaerobic pond, a frame trickling filter, a regulating pond, a ladder with a water wheel, an oxidation Pond and a surface flow artificial wetland, the baffle anaerobic pond is an anaerobic pond with 6 partitions alternately arranged on the top and bottom of the pool, and a baffle channel is formed in the baffle anaerobic pond, the distance between the partitions is 25cm, and the baffle The thickness of the activated carbon layer at the bottom of the anaerobic tank is 15cm; the frame trickling filter is equipped with a soil layer, a ceramsite layer, an activated carbon layer, and a sand layer from top to bottom. The thickness of the soil layer is 50cm. The average particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com