A recycling process for waste emulsion

A waste emulsion and treatment process technology, which is applied in the field of waste emulsion resource treatment process, can solve the problems of unsatisfactory treatment effect, unsatisfactory evaporation of emulsion, and low cost investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The resource treatment process of embodiment 1 waste emulsion

[0031] The recycling process of waste emulsion is handled according to the following procedures:

[0032] (1) Coarse filtration → (2) Separation of organic phase → (3) First stage purification → (4) Second stage purification → (5) Third stage purification → (6) Evaporation → (7) Biochemical treatment.

Embodiment 2

[0033] The resource treatment process of embodiment 2 waste emulsion

[0034] The resource treatment process of waste emulsion is processed according to the following steps:

[0035]Step (1) Coarse filtration: Take the waste emulsion and use a grid wire mesh with a side length of 0.1-0.3 cm to perform pre-coarse filtration to obtain filtrate a;

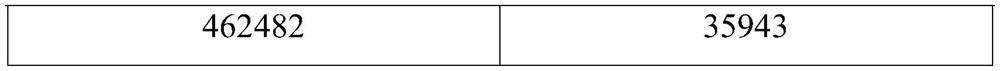

[0036] Table 1 shows the COD value and ammonia nitrogen content of the detected filtrate a.

[0037] Table 1 COD value and ammonia nitrogen content of filtrate a

[0038]

[0039]

[0040] Step (2) Separating the organic phase: stirring the filtrate a obtained in step (1) for 5 minutes, standing for more than 30 minutes and stratifying: separating the uppermost oil phase, and then the lower emulsified layer and aqueous phase liquid for standby;

[0041] Step (3) first-stage purification: the emulsified layer and the aqueous layer liquid obtained in step (2) are transferred to the reactor, and the calcium oxide equivalent to 0....

Embodiment 3

[0058] The resource treatment process of embodiment 3 waste emulsion

[0059] The resource treatment process of waste emulsion is processed according to the following steps:

[0060] Step (1) Coarse filtration: Take the waste emulsion and use a grid wire mesh with a side length of 0.1-0.3 cm to perform pre-coarse filtration to obtain filtrate a;

[0061] Table 6 shows the COD value and ammonia nitrogen content of the detected filtrate a.

[0062] Table 6 COD value and ammonia nitrogen content of filtrate a

[0063] COD (mg / l) Ammonia nitrogen (mg / l) 395868 40268

[0064] Step (2) Separating the organic phase: stirring the filtrate a obtained in step (1) for 20 minutes, standing for more than 30 minutes and stratifying: separating the uppermost oil phase, and then the lower emulsified layer and aqueous phase liquid for standby;

[0065] Step (3) first-stage purification: the emulsified layer and the aqueous phase layer liquid obtained in step (2) are tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com