Moving handrail guiding assembly of guardrail column part of escalator or moving walking escalator

A technology for guiding components and walking ladders, used in escalators, transportation and packaging, etc., can solve the problems of shortening the service life of handrails and bearings, incomplete filling of bearing structures, increasing personnel and labor costs, etc. The effect of dust accumulation, few parts, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. The directions involved in the description are the directions shown in the accompanying drawings, and the directions are only used to describe orientations and not to limit.

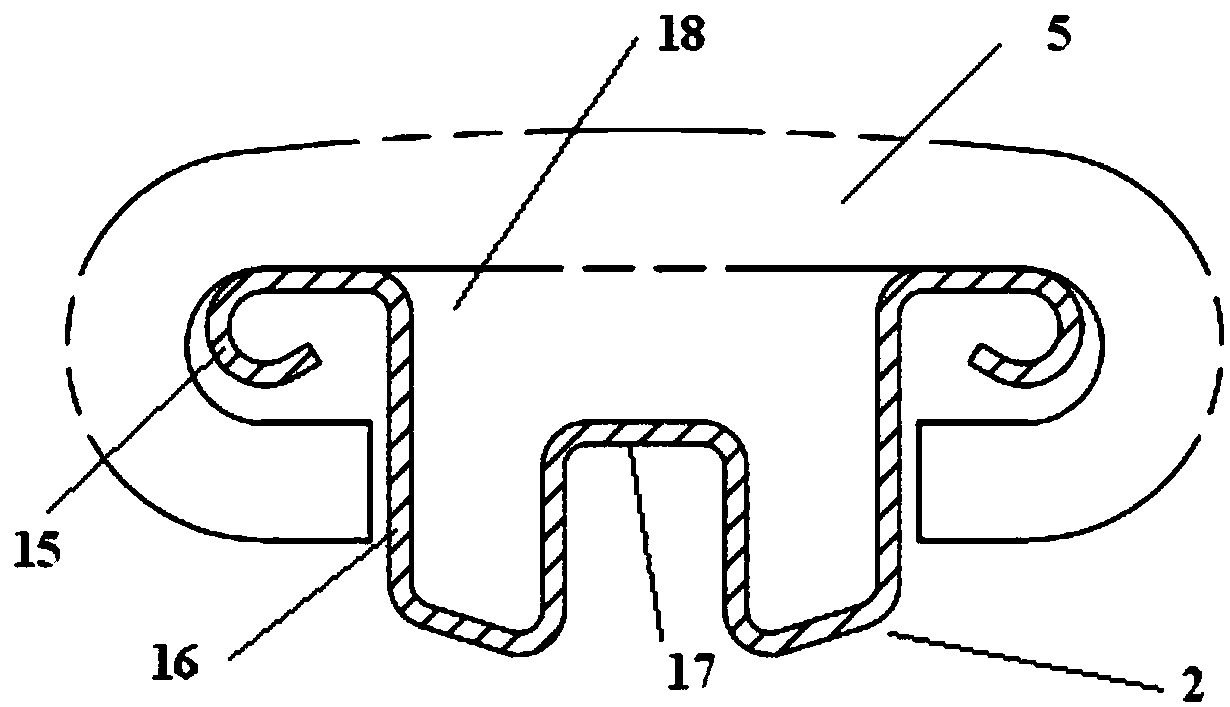

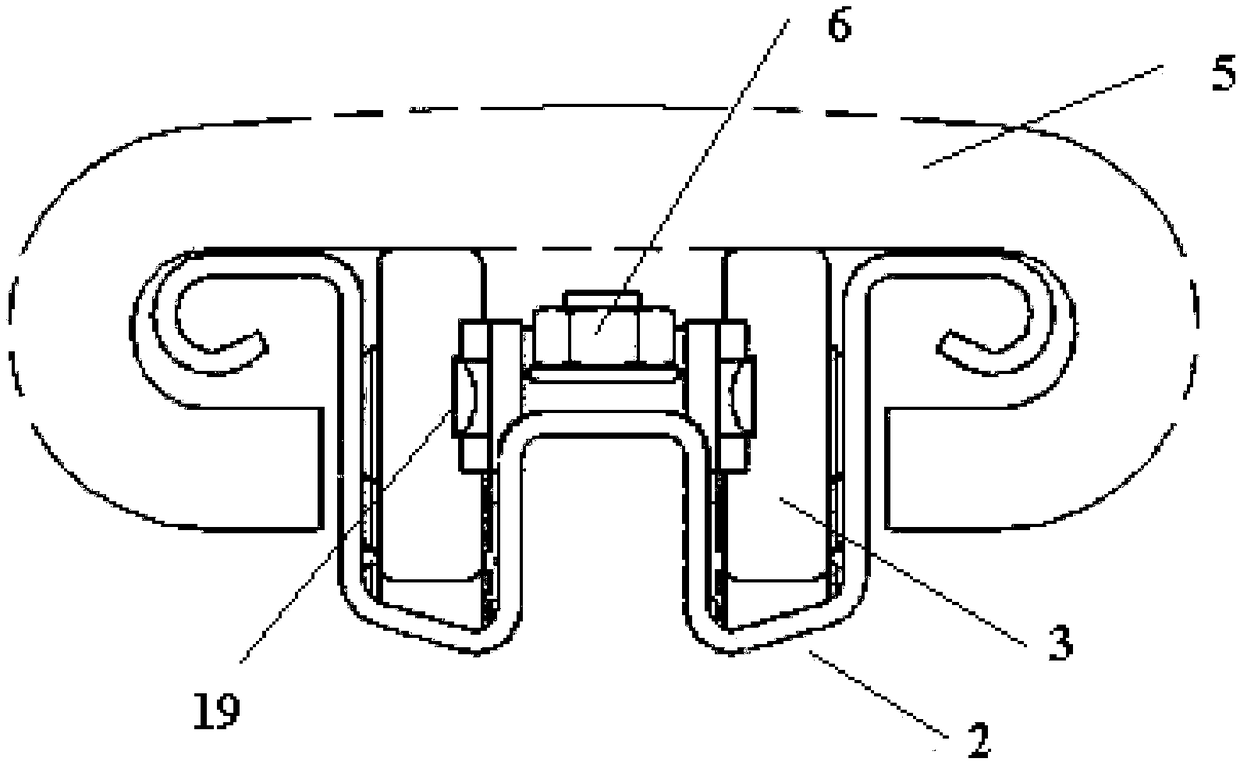

[0044] The present invention proposes a new guide assembly for a balustrade section of an escalator comprising a support profile and a low coefficient of friction part or chain of low friction subparts. The low coefficient of friction component comprises a single component, the chain of low coefficient of friction subcomponents comprises a plurality of low coefficient of friction subcomponents, the low coefficient of friction component or low coefficient of friction subcomponents are composed of a material having a low coefficient of friction.

[0045] Figure 4 is a cross-sectional view of a guide assembly according to an embodiment of the present invention taken along a direction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com