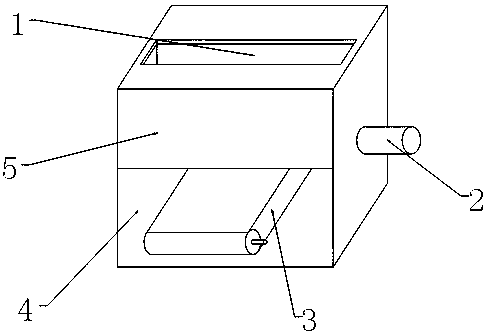

Discharging device for high-efficiency rolling noise reduction type industrial machine

A discharge device, industrial machinery technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of loud noise, noise pollution, damage to processed products, etc., and achieve the effect of solving loud noise and reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

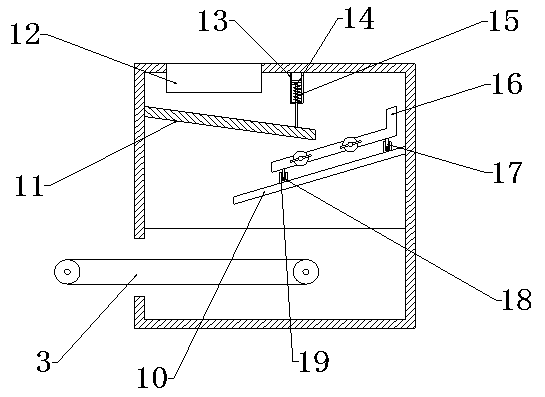

[0019] Specific implementation method: when in use, the user first turns on the motor 2, the motor 2 works to make the power shaft rotate, the power shaft rotates to make the conveyor belt 3 work, and then the externally processed product enters the inside of the hollow box 5 through the feed port 12, and then processed The product leaves the feed port 12 and falls on the upper end of the feed plate 11, and then the feed plate 11 rotates clockwise around the rotating shaft under the gravity of the processed product, and the clockwise rotation of the feed plate 11 drives the T-shaped bar-14 to move downward, T The downward movement of the bar-14 causes the spring-15 to compress and generate elastic force, and the elastic force of the spring-15 hinders the downward movement of the T-bar-14, so that the gravity of the processed product is converted into the elastic force of the spring-15, thereby preventing the product from falling to the feeding plate 11. The processed products o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com